Liquid crystal display panel and production method thereof

A technology of liquid crystal display panel and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., and can solve the problems of decreased storage capacitance value and poor capacitance effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

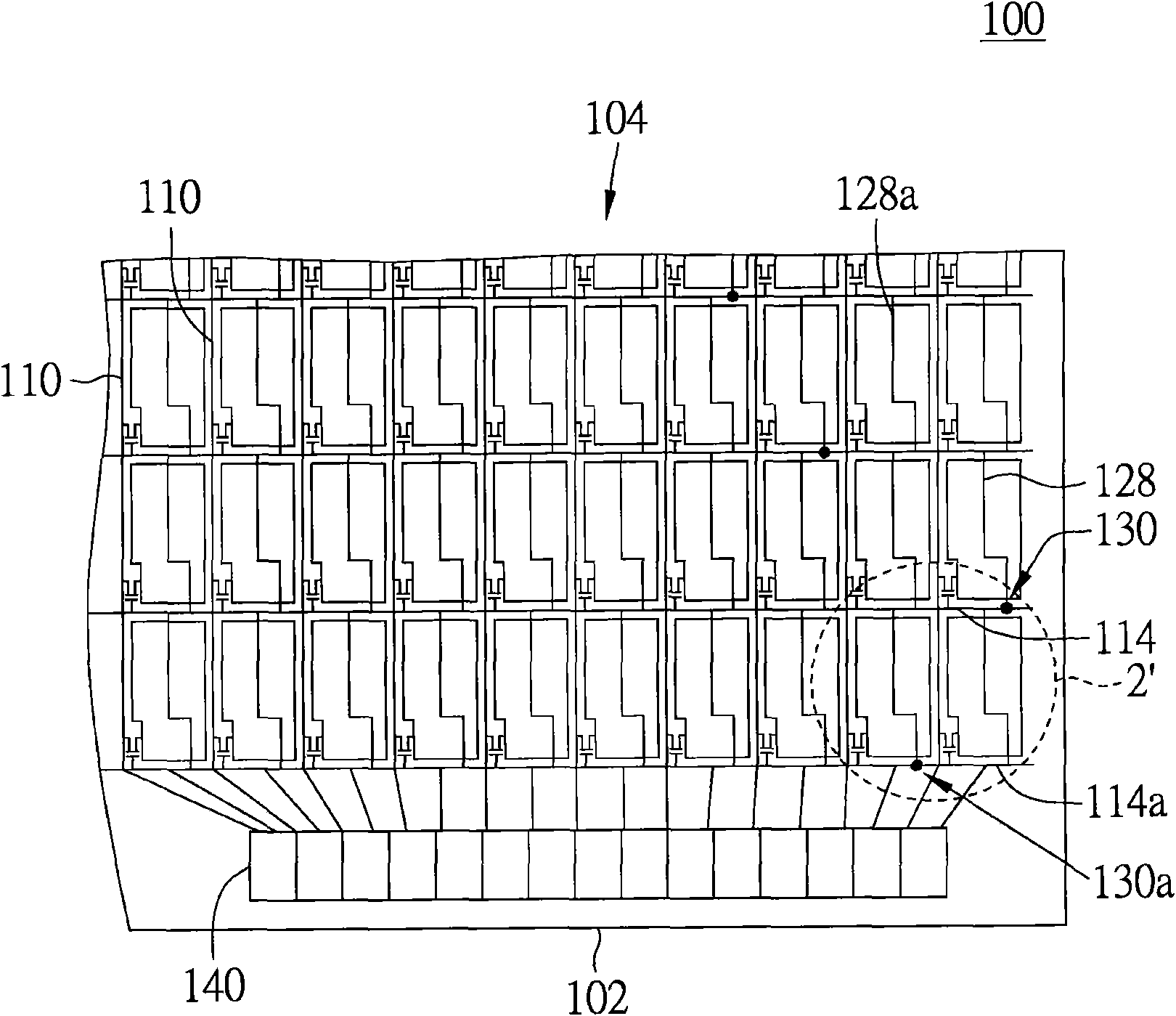

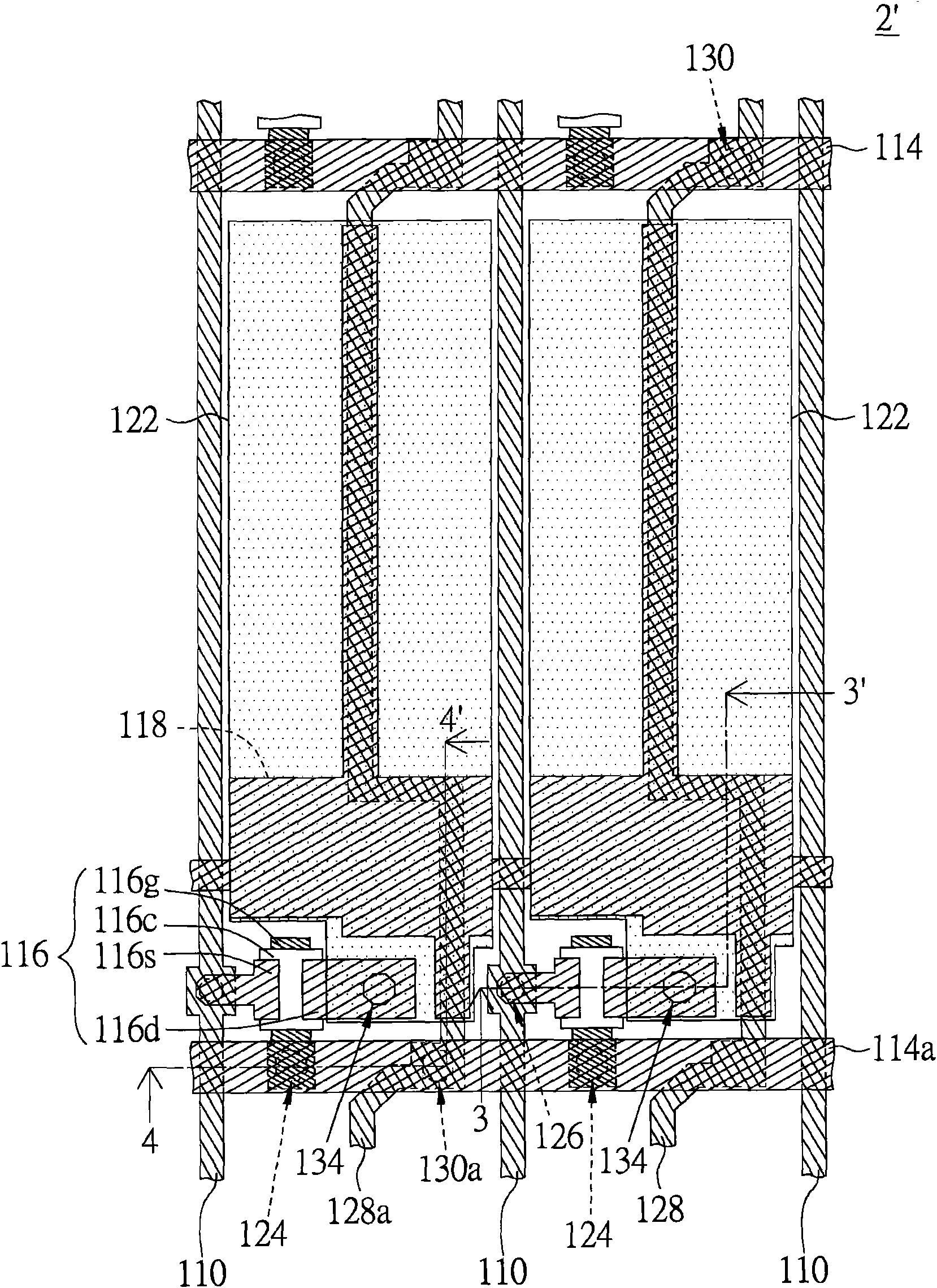

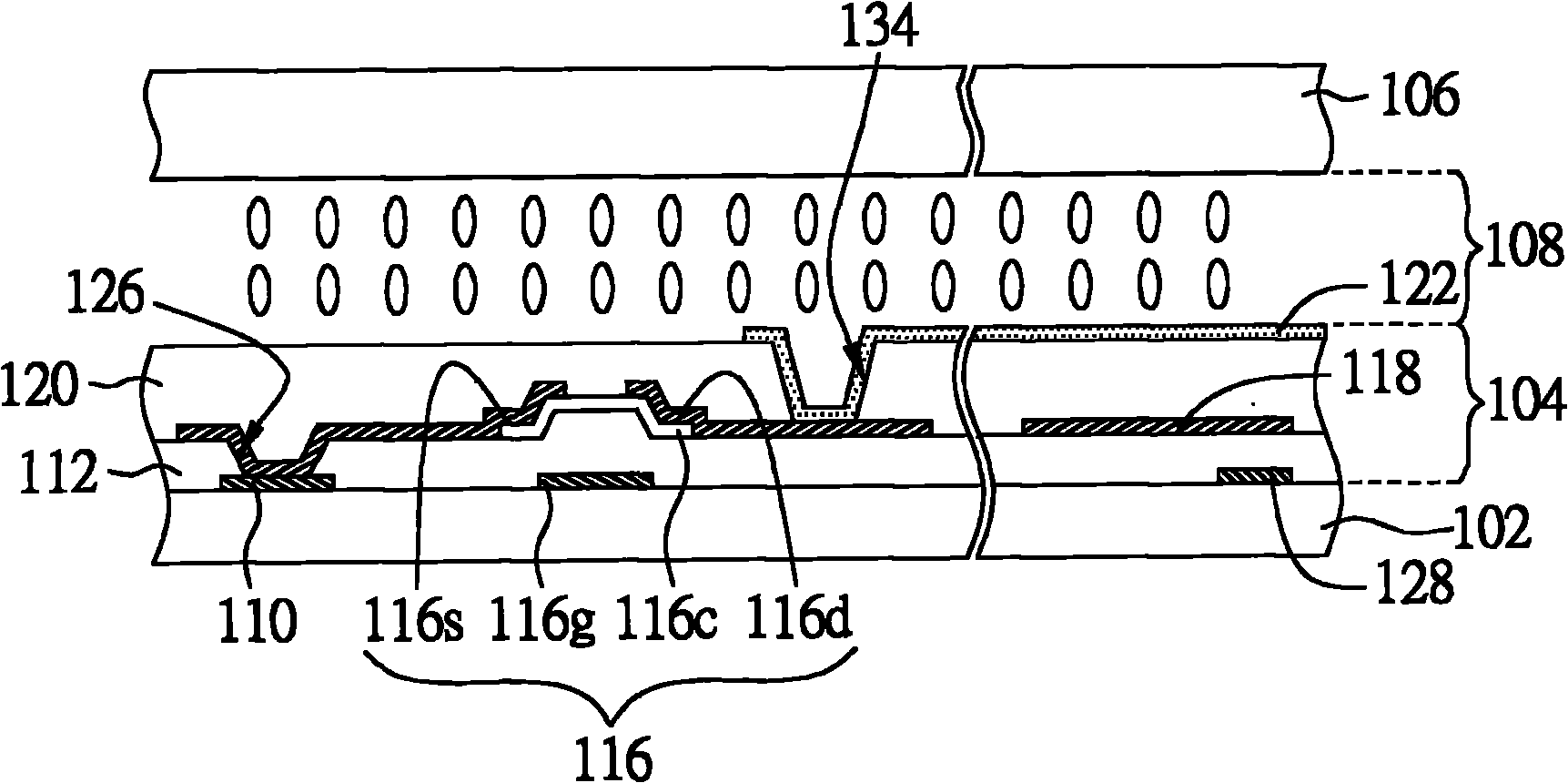

[0044] Please refer to Figure 1 to Figure 3 , figure 1 A partial schematic diagram of a liquid crystal display panel according to a first embodiment of the present invention is shown, figure 2 draw figure 1 The enlarged schematic diagram of the middle part 2', image 3 draw figure 2 Sectional view of 3-3' in the middle direction. Such as figure 1 , the liquid crystal display panel 100 includes a first substrate 102, a pixel array 104, and a second substrate 106 (shown in image 3 ), liquid crystal layer 108 (shown in image 3 ) and drive circuit 140. The liquid crystal layer 108 is disposed between the first substrate 102 and the second substrate 106 .

[0045] Please also refer to figure 2 and image 3 The pixel array 104 is formed on the first substrate 102 and includes several data lines 110, several scan lines 114, several active elements 116, several capacitor electrodes 118, several pixel electrodes 122 and several gate lines 128 . Among them, adjacent ca...

no. 2 example

[0067] Please refer to Figure 7 , which shows a partial schematic diagram of a liquid crystal display panel according to a second embodiment of the present invention. The parts in the second embodiment that are the same as those in the first embodiment use the same reference numerals, which will not be repeated here. The difference between the liquid crystal display panel 200 of the second embodiment and the liquid crystal display panel 100 of the first embodiment is that the liquid crystal display panel 200 does not include the gate lines 128 and the scan line openings 130 .

[0068] Please refer to Figure 8 , which shows Figure 7 Sectional view in the middle direction 8-8'. The liquid crystal display panel 200 includes a first substrate 102 , a pixel array 204 , a second substrate 106 and a liquid crystal layer 108 .

[0069] The pixel array 204 includes several data lines 210 , a first insulating layer 212 , several scan lines 214 , several active elements 216 , seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com