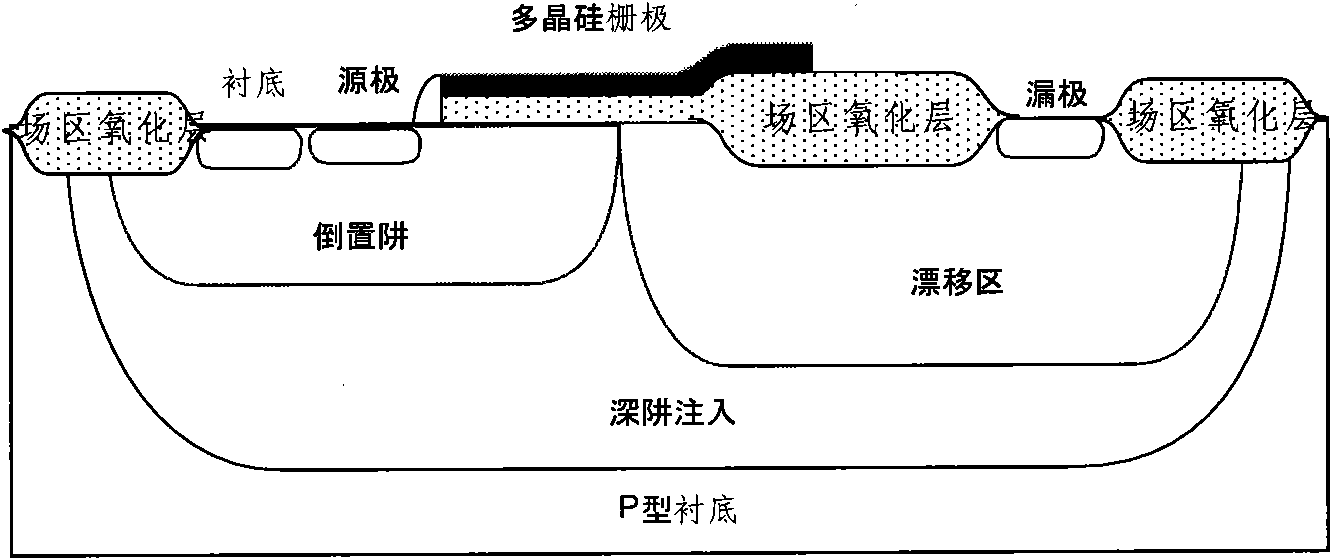

Method of improving consistence and stability of LDMOS (Laterally Diffused Metal Oxide Semiconductor) performance

A consistent and stable technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting device performance consistency, etc., to improve consistency and stability, improve uniformity, and reduce width. effect of difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

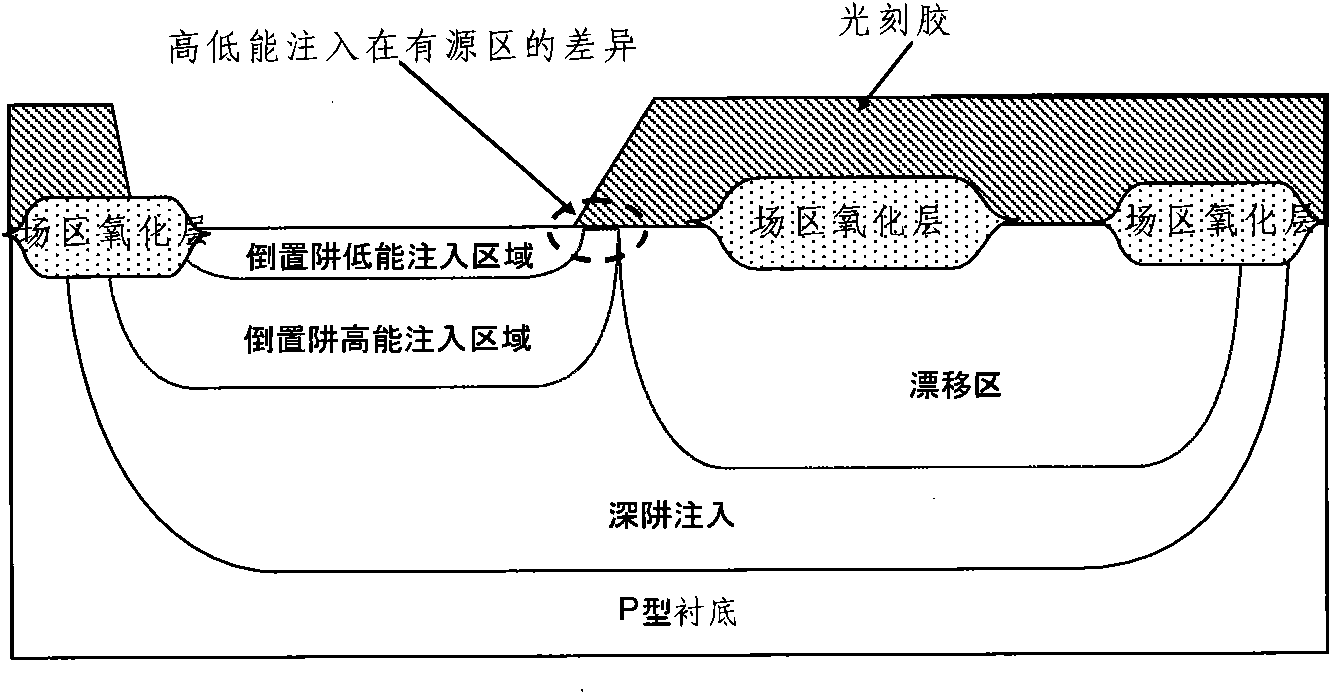

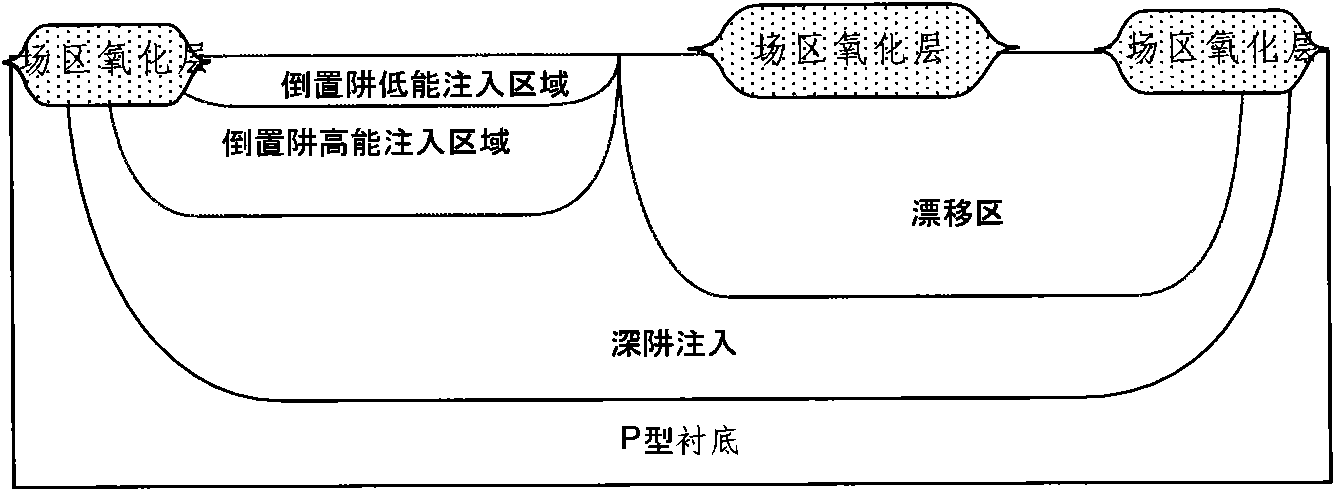

[0035] Such as image 3 As shown, the key of the present invention is to adjust the size of the photolithography window between high-energy and low-energy implantation, narrow the difference in width between high-energy and low-energy implantation, and improve the uniformity of impurity distribution in the LDMOS channel. Therefore, the consistency and stability of the performance of the LDMOS device are improved.

[0036] Such as Figure 4-Figure 7 As shown, a method for improving the consistency and stability of laterally diffused metal oxide semiconductor device performance by using plasma etching to adjust the size of the photolithographic window for protecting between high-energy and low-energy implants according to the present invention includes: :

[0037] Step 1, using photolithography to form an inverted well and inject a photoresist window;

[0038] Step 2, high-energy ion implantation;

[0039] Step 3, using plasma etching to expand the photoresist window;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com