Production of lactams and carboxylic acid amides by beckman rearrangement of oximes in the presence of nb catalysts

A technology of Beckmann rearrangement and catalyst, which is applied in the field of preparing lactam and carboxylic acid amide through Beckmann rearrangement of oxime in the presence of Nb catalyst, which can solve the problems of salt pollution, catalyst deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

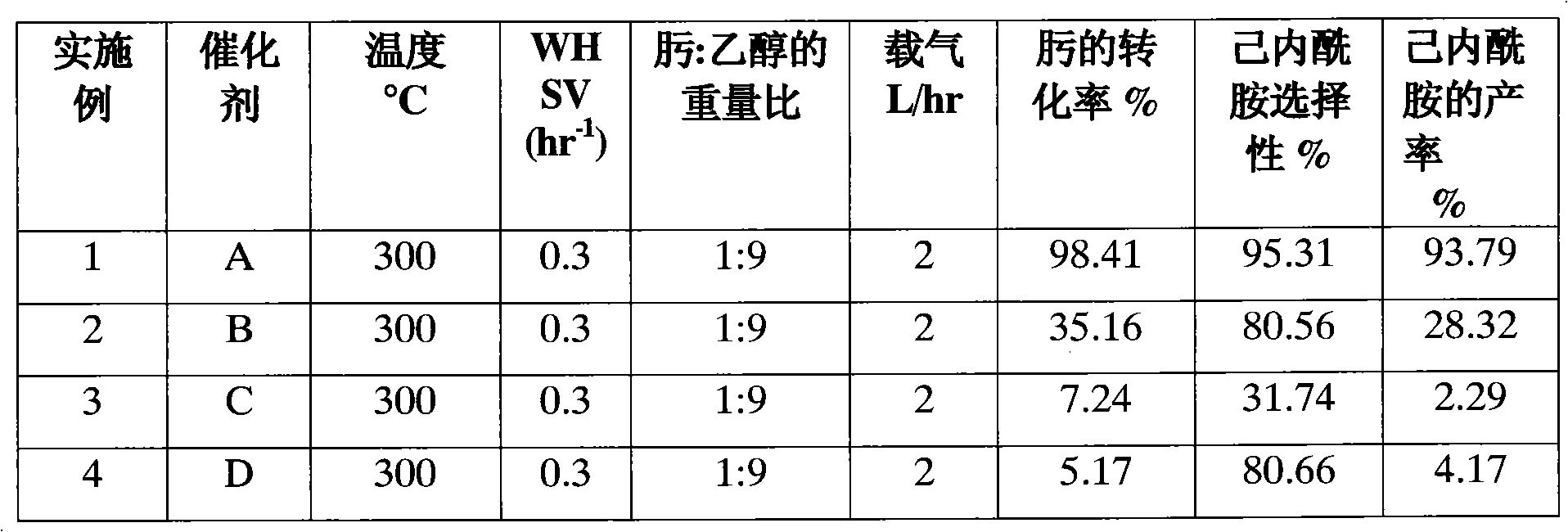

[0065] Example 1: Catalyst A

[0066] SiO 2 The Nb on the support is prepared by the impregnation method. The catalyst is synthesized by the following method: DAVICAT SP 550-10021 (surface area = ~ 300m 2 / g) is used as a silica carrier. By using NbCl 5 Impregnation to prepare Nb / SiO 2 . During its preparation, first add an appropriate amount of NbCl 5 Dissolve in 100ml isopropanol. Add 10g SiO to this solution 2 Carrier material. The mixture obtained therefrom was stirred at 110°C until the isopropanol had evaporated. After impregnation, the sample was dried at 110°C for 4 hours and calcined in an air stream at 400°C for 4 hours.

Embodiment 2

[0067] Example 2: Catalyst B

[0068] SiO 2 -Al 2 O 3 The Nb on the support material was prepared by the same synthesis method as in Example 1. In this embodiment, SiO 2 -Al 2 O 3 (60:40) SASOL SIRAL-40 (BET area = 520m 2 / g) is used as a carrier material.

Embodiment 3

[0069] Example 3: Catalyst C

[0070] TiO 2 The Nb on the support material was also prepared by the impregnation method as in Example 1, except that TiO 2 Instead of SiO 2 As a carrier material. Hombicat II type from Sachtleben company is used as TiO 2 Source, its BET surface area is m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com