Compaction tool for filter core of oil filter

A technology of oil filter and filter element, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problem of no plant powder or particles found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

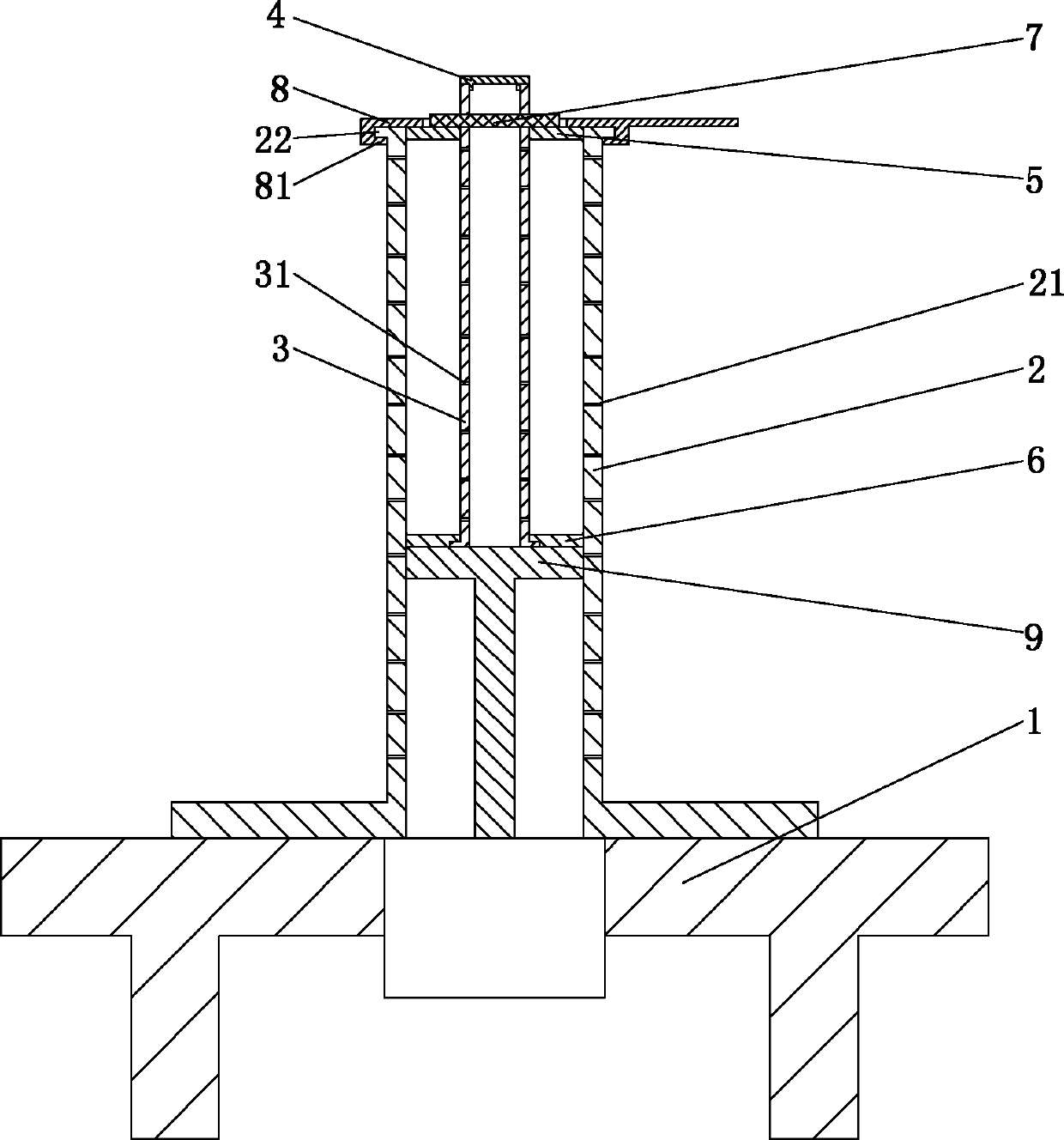

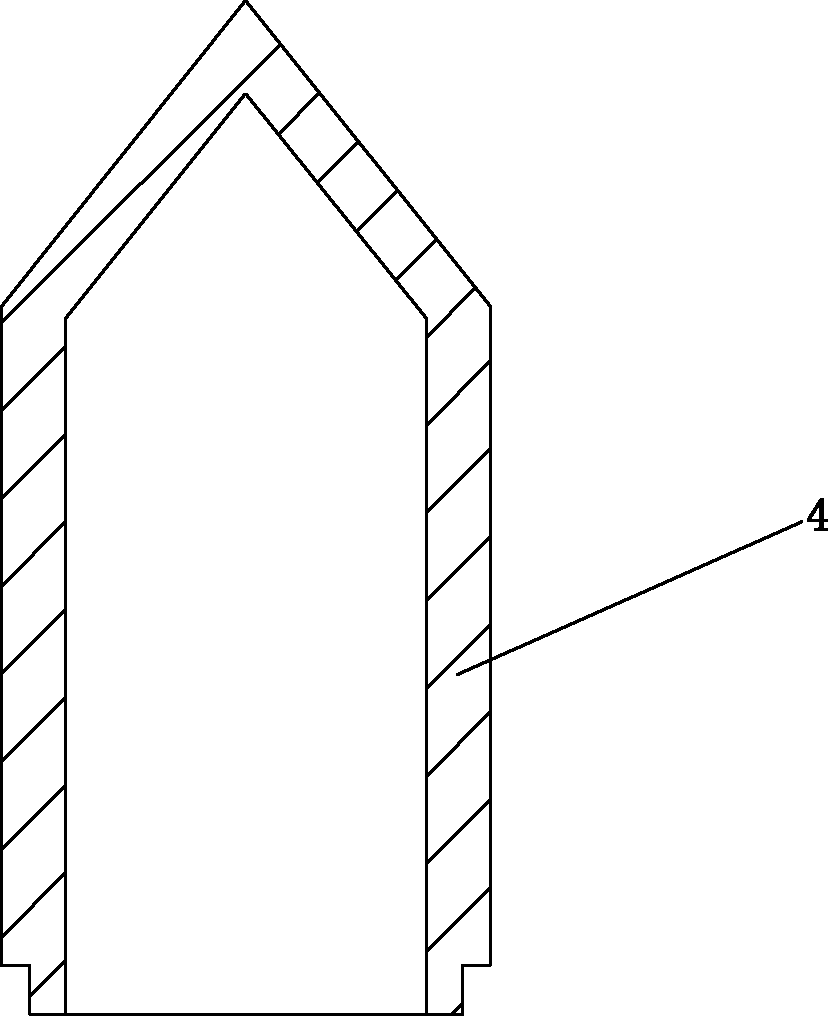

[0022] Such as Figure 1-6 As shown in one, the present invention comprises a frame 1, which also includes an outer grinding cylinder 2, an inner cylinder 3, an inner cylinder cover 4, an inner cylinder upper cover 5, an inner cylinder lower cover 6 and a pressing plate 8, and the outer grinding cylinder 2 is Hollow cylindrical, which is fixed on the frame 1, and the inner sleeve is provided with a hydraulically driven top pressure plate 9; Put it into the outer grinding cylinder 2 and press against the top pressure plate 9; the upper end of the inner cylinder 3 is provided with an inner cylinder cover 4; when compacting the filter element of the oil filter, the material for preparing the filter element is filled in the outer grinding cylinder 2 and the In the gap between the inner cylinders 3, the inner cylinder upper cover 5 is sleeved on the upper part of the inner cylinder 3 against the material for preparing the filter element; the pressure plate 8 is inserted from the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com