Continuous sand filtration apparatus

A continuous type, sand filtration technology, applied in the direction of filtration separation, filtration circuit, gravity filter, etc., can solve the problems of unstable water output and water quality, and achieve the effect of stable water volume, stable water quality and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

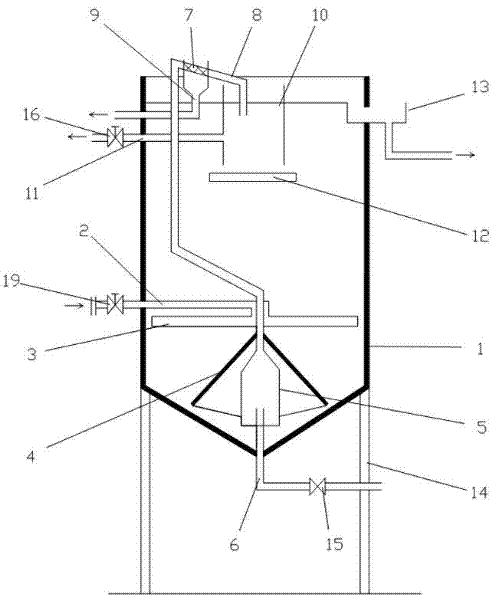

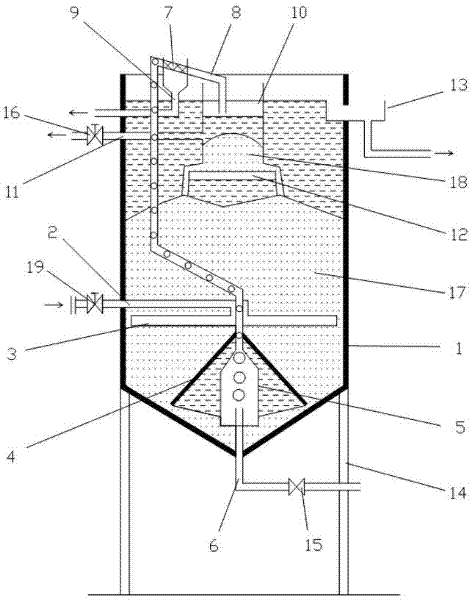

[0038] Please refer to figure 1 and figure 2 , a continuous sand filter equipment, including a cylinder 1 and a sand filter device, the bottom of the cylinder 1 is conical. In the present invention, the upper part of the cylinder 1 is a straight wall, and the lower part is a cone, but the upper part of the cylinder 1 of the present invention is not limited thereto. The sand filter device is arranged in the cylinder body 1, wherein the sand filter device includes a sand bed 17, an air inlet pipe 6, an air lift pipe 5, a water filtration flow channel 7, a raw water distribution deflector 3, a grit chamber 10, and a floating support plate 12 and clean water outlet weir 13:

[0039] The sand bed 17 is used for filtering sewage, the sand bed 17 is located in the cylinder body 1, and the sand bed 17 is formed by filter sand. That is, filter sand is injected into the cylinder body 1 , and the upper plane of the filter sand (that is, the upper plane of the sand bed 17 ) is below t...

Embodiment 2

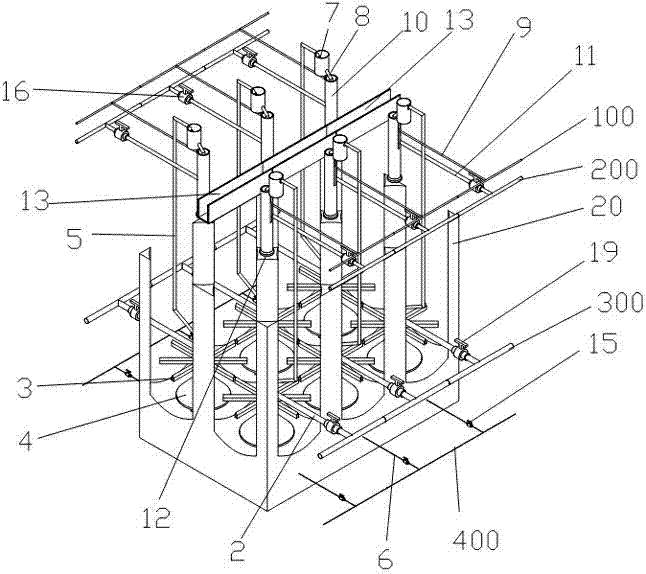

[0054] Please refer to image 3 , a continuous type sand filter equipment, including a filter tank and several sand filter devices, the sand filter device in this embodiment has the same structure as the sand filter device in Embodiment 1, therefore, the labels of the internal parts of the sand filter device in this embodiment What is indicated in Embodiment 1 is used, and will not be described in detail below. The bottom of the filter tank includes several cone-shaped bottoms, which are evenly arranged at the bottom of the pool. Of course, it is also possible that some cone-shaped bottoms are not evenly arranged at the bottom of the pool. The present invention does not limit this. For ease of use and the convenience of maintenance, in this embodiment, several conical bottoms are evenly arranged at the bottom of the filter tank. Several columns 20 are also arranged in the filter tank, and the columns 20 are arranged between each conical bottom to prevent the filter sand from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com