Method for purifying injection sodium chloride

A purification method and sodium chloride technology, applied in the field of pharmaceutical preparation, can solve the problems of increased reagent cost, high energy consumption, complicated operation, etc., and achieve the effects of avoiding solid waste, stable effluent quality, and low impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

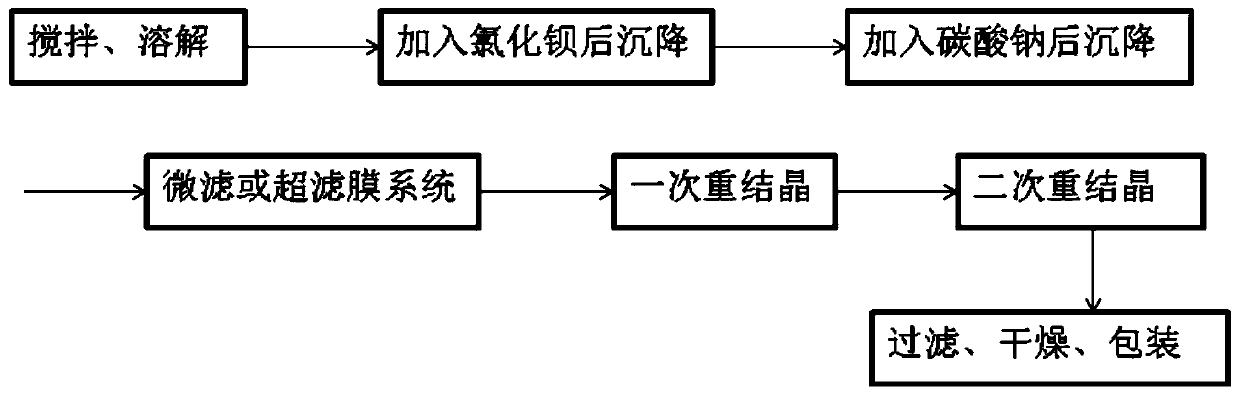

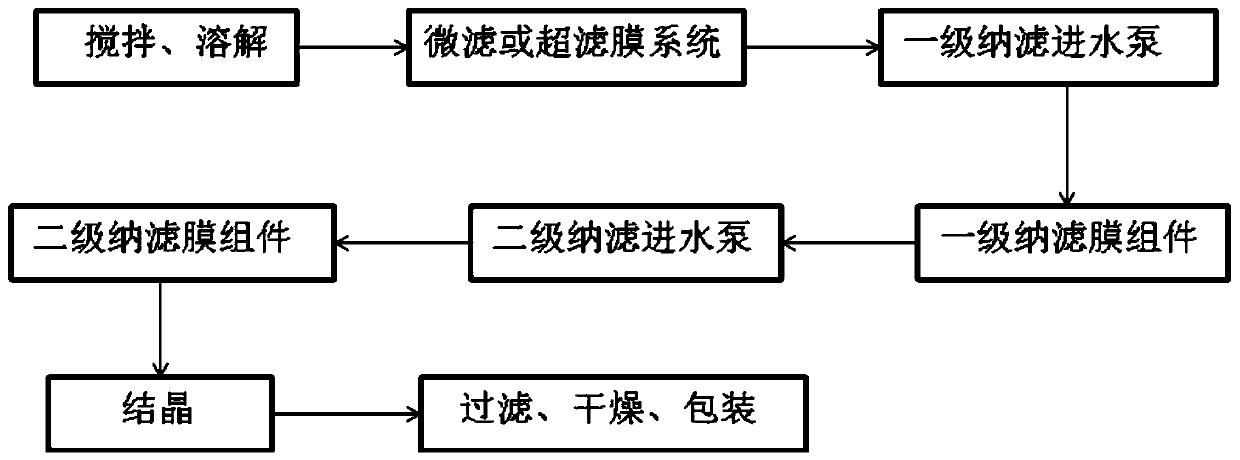

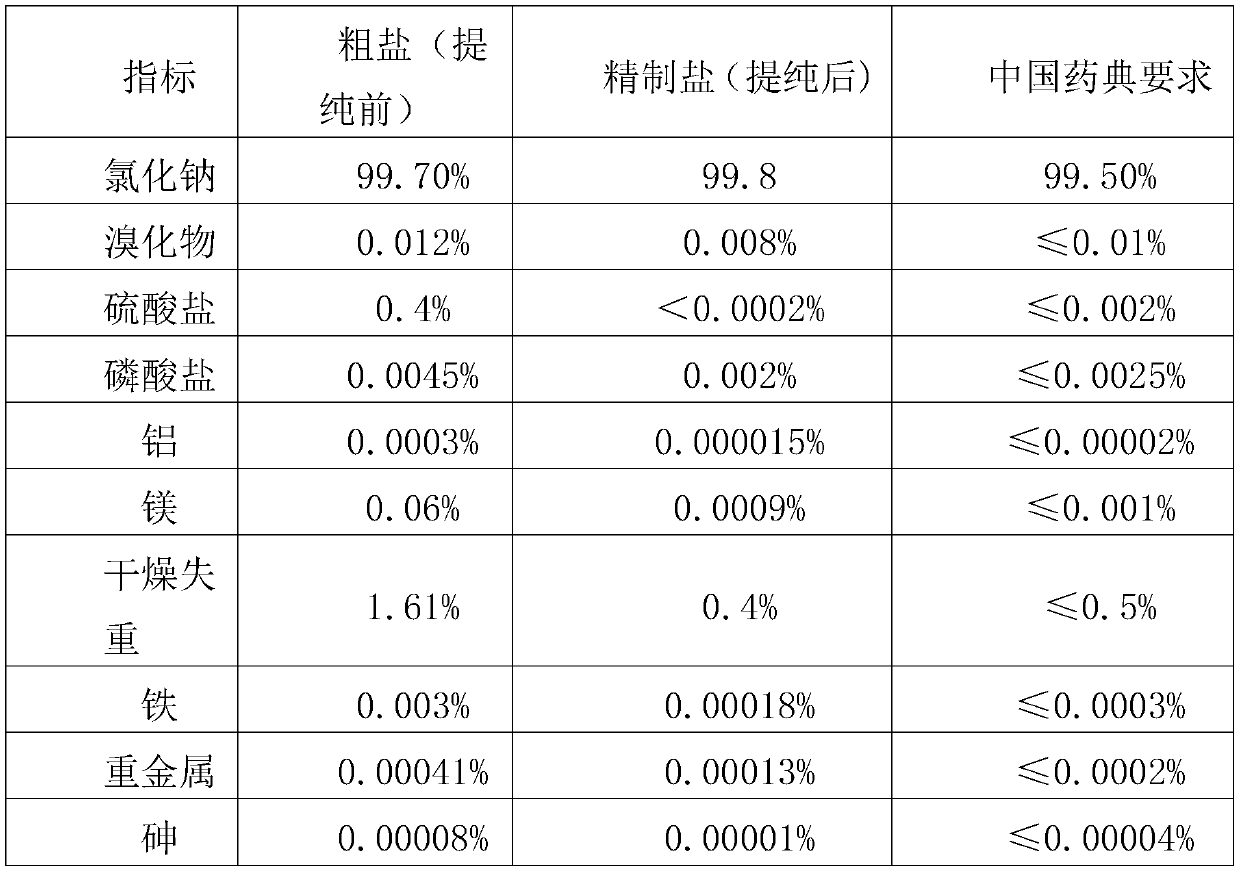

[0019] Such as figure 1 Shown, a kind of injection sodium chloride purification process specifically comprises the following steps:

[0020] (1) Add crude salt into pure water, heat and stir to make it fully dissolved, and dissolve into a 300g / L sodium chloride solution. In addition to calcium, magnesium, iron and some heavy metal elements, the solution also contains about 2g / L of sodium sulfate, this solution is pre-filtered, the pre-filtration adopts a microfiltration or ultrafiltration system, the filter membrane used is polysulfone, polyethersulfone or polyvinylidene fluoride, and the feed water pressure is <10bar. The recovery rate of the solution is higher than 99%, and it can filter out particles with a particle size of 0.01-0.1μm. The molecular weight cut-off is 1000-30000Da, which is used to remove suspended solids in the solution, so that the turbidity of the solution after filtration is <0.5NT. Can greatly reduce nanofiltration membrane fouling in subsequent proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com