Unit type flexo printing machine driving system

A transmission system, flexo printing press technology, applied in printing, printing presses, rotary printing presses, etc., can solve problems such as difficulty in ensuring high-precision and high-quality printing results, increased control complexity, easy shaking or wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

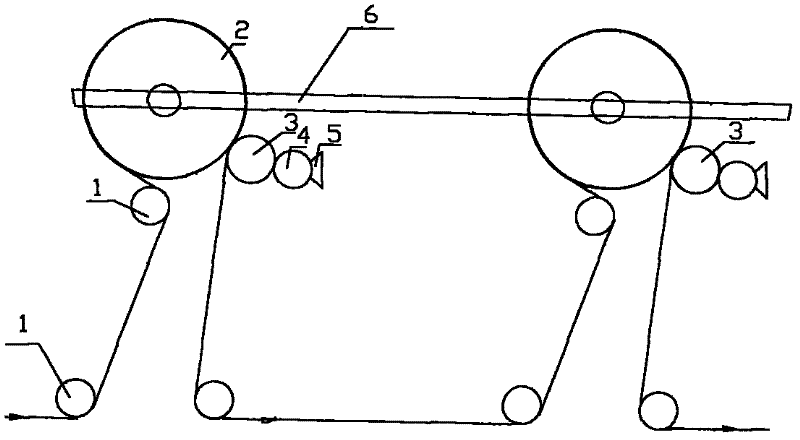

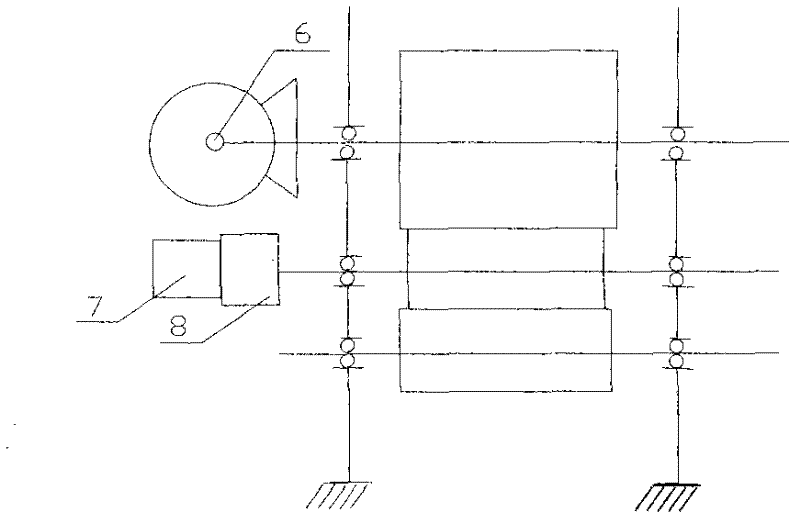

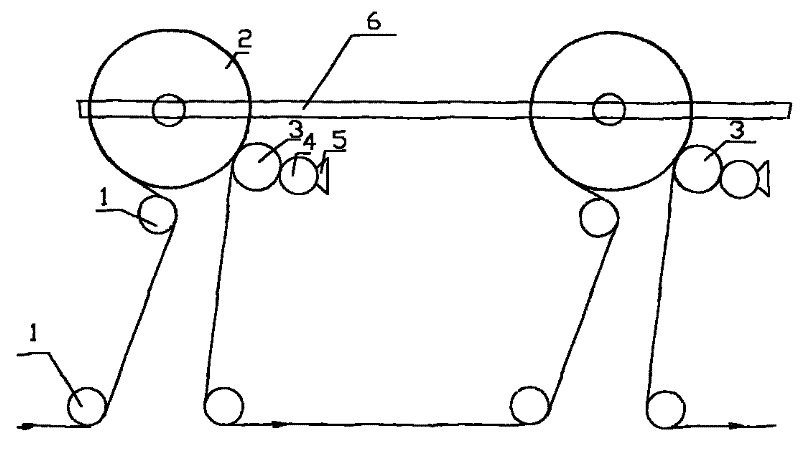

[0017] The transmission system of this unit type flexo printing machine includes the main drive shaft 6, embossing roller 2, motor 7, gearbox 8, plate roller 3, transmission timing belt or gear, anilox roller, scraping mechanism 5, etc., embossing roller 2 Driven coaxially by the transmission spindle 6, the version roller 3 is driven separately by the motor 7, so that the surface speed of the version roller 3 and the embossing roller 2 are synchronized and consistent; the driving power of the anilox roller 4 can be driven by the version roller provided by the motor, or by the drive spindle.

[0018] The driving motor 7 of the version roller 3 can be any one of servo motor, synchronous motor and frequency conversion motor. When the machine is working, the surface line speed of the version roller and the embossing roller can be consistent. When an overprint error occurs, the motor sends a signal through the controller. Superimpose a correction amount to quickly correct the error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com