Feeding cabin with composite air ventilation structure

A ventilation structure and feeding bin technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of not giving the structural characteristics and dimensions of the main part of the container and the bottom unloading device, etc., to improve the mass flow rate of the discharge , smooth discharge and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

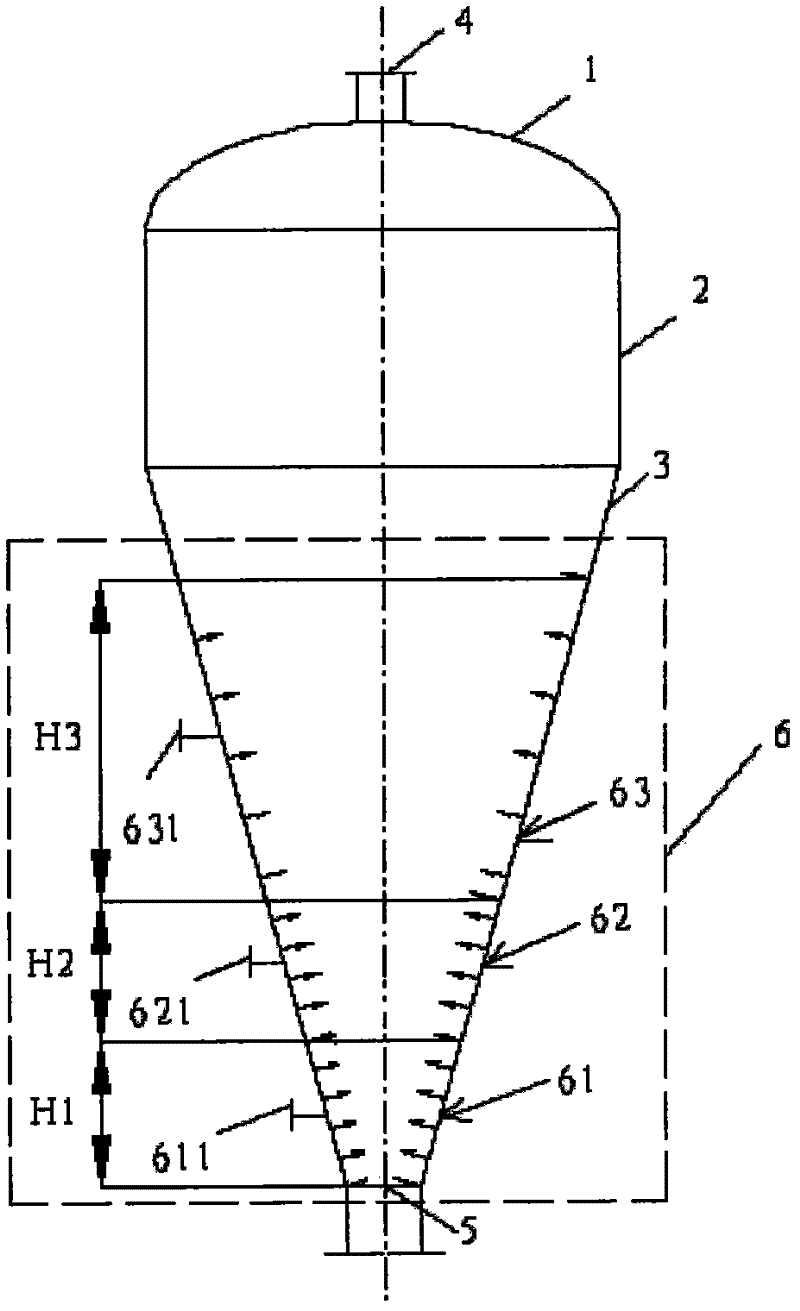

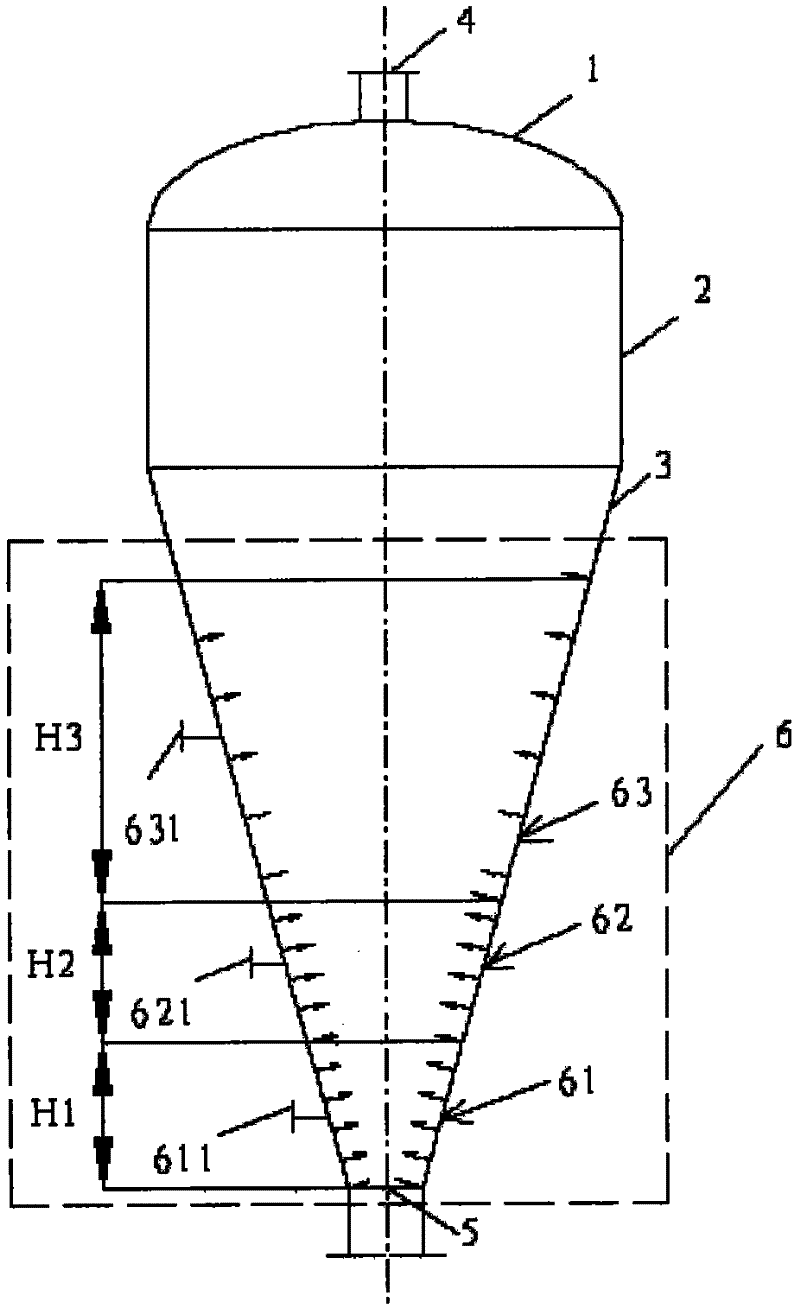

[0025] Such as figure 1 Described, the feeding bin with compound ventilation structure of the present invention comprises a cone angle and is the conical container 3 of 30 °, and the bottom of this conical container 3 has a discharge opening 5, and the diameter of this discharge opening 5 is 300mm. A cylindrical container 2 connected with the conical container 3 is arranged above the conical container 3 , and a sealing head 1 is arranged above the cylindrical container 2 , and a feed inlet 4 is provided on the sealing head 1 .

[0026] On the inner wall of the conical container 3 is an inflator 6 . The inflation device 6 includes a first inflation mechanism 61 near the position of the discharge opening 5, the first inflation mechanism 61 extends upwards to a height H1 based on the discharge opening, and the height H1 is 0.87 times the diameter of the discharge opening 5, That is, H1=261mm. An air inlet 611 is provided on the side wall of the conical container 3 correspondin...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 lies in that the cone angle of the conical container 3 is 40°, and the diameter of the discharge opening 5 is 200 mm. The height H1 of the first inflatable mechanism 61 is 1.6 times of the diameter of the discharge port, that is, H1=320mm; the height H2 of the second inflatable mechanism 62 is 1.1 times of the diameter of the discharge port, that is, H2=220mm; the third inflatable mechanism 63 The height H3 is 9.6 times of the diameter of the discharge opening, that is, H3=1920mm.

[0034]Taking pulverized coal as an example, nitrogen gas is input into the conical container 3 . When the feed pressure is 0.8MPa and the temperature is 80°C, the apparent gas velocity of the side wall of the first inflator 61 is about 55mm / s, and the ventilation volume is about 480Nm 3 / h The superficial gas velocity of the side wall of the second inflatable mechanism 62 is about 45mm / s, and the ventilation volume is about 425Nm 3 / h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com