Gradation design method of tailing autoclaved bricks

A design method and technology of autoclaved bricks, applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of increased labor intensity, low utilization rate of tailings, fine particle size, etc., and reduce labor Strength, high utilization rate of tailings, and the effect of reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

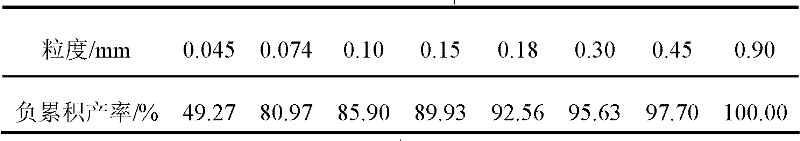

[0020] A gradation design method for tailings autoclaved bricks. The tailings storage capacity of a hematite mine is about to reach the maximum storage capacity and service life of the design. In order to solve the problem of comprehensive utilization of tailings, reduce the amount of tailings in the storage, and prolong the life of the existing tailings storage, hematite tailings Prepare autoclaved bricks as the main raw material. The mine has no requirements on the utilization rate of the tailings pond, and the particle size characteristics of the tailings are shown in Table 1.

[0021] Table 1 The particle size characteristics of a certain hematite tailings

[0022]

[0023] The gradation design steps of the tailings autoclaved brick of the present embodiment are:

[0024] Combined with the particle size characteristics of the hematite tailings shown in Table 1, select the maximum particle size d of the aggregate max = 5.0 mm.

[0025] Then determine the gradation co...

Embodiment example 2

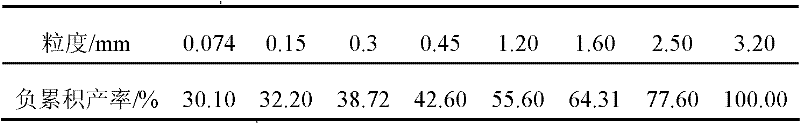

[0047] A gradation design method for tailings autoclaved bricks. The tailings storage capacity of a gold mine is about to reach the maximum storage capacity and service life of the design. In order to solve the comprehensive utilization of tailings, reduce the amount of tailings in the storage, and prolong the life of the existing tailings storage, the gold mine tailings are used as the The main raw material is to prepare autoclaved bricks. The mine has no requirements on the utilization rate of the tailings, and the particle size characteristics of the tailings are shown in Table 2.

[0048] Table 2 Particle size characteristics of a gold mine tailings

[0049]

[0050] The gradation design steps of the tailings autoclaved brick of the present embodiment are:

[0051] Combined with the particle size characteristics of the gold mine tailings shown in Table 2, select the maximum particle size d max = 5.0 mm.

[0052] Then determine the gradation correction index K: the m...

Embodiment example 3

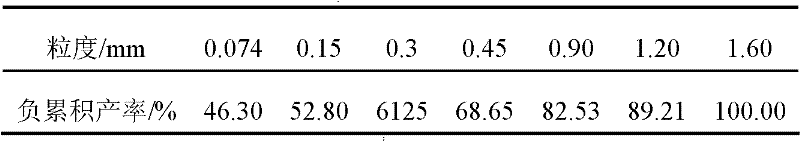

[0075]A gradation design method for tailings autoclaved bricks. The tailings storage capacity of a copper mine is about to reach the maximum storage capacity and service life of the design. In order to solve the comprehensive utilization of tailings, reduce the amount of tailings in the storage, and prolong the life of the existing tailings storage, the copper mine tailings are used as the The main raw material is to prepare autoclaved bricks. The mine requires a tailings utilization rate of 80%, and the tailings particle size characteristics are shown in Table 3 below.

[0076] Table 3 Particle size characteristics of a copper mine tailings

[0077]

[0078] The gradation design steps of the tailings autoclaved brick of the present embodiment are:

[0079] Combined with the particle size characteristics of the copper ore tailings shown in Table 3, select the maximum particle size d of the aggregate max = 2.5 mm.

[0080] Then determine the grading correction index K: S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com