Patents

Literature

34 results about "CD1" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CD1 (cluster of differentiation 1) is a family of glycoproteins expressed on the surface of various human antigen-presenting cells. They are related to the class I MHC molecules, and are involved in the presentation of lipid antigens to T cells. However their precise function is unknown.

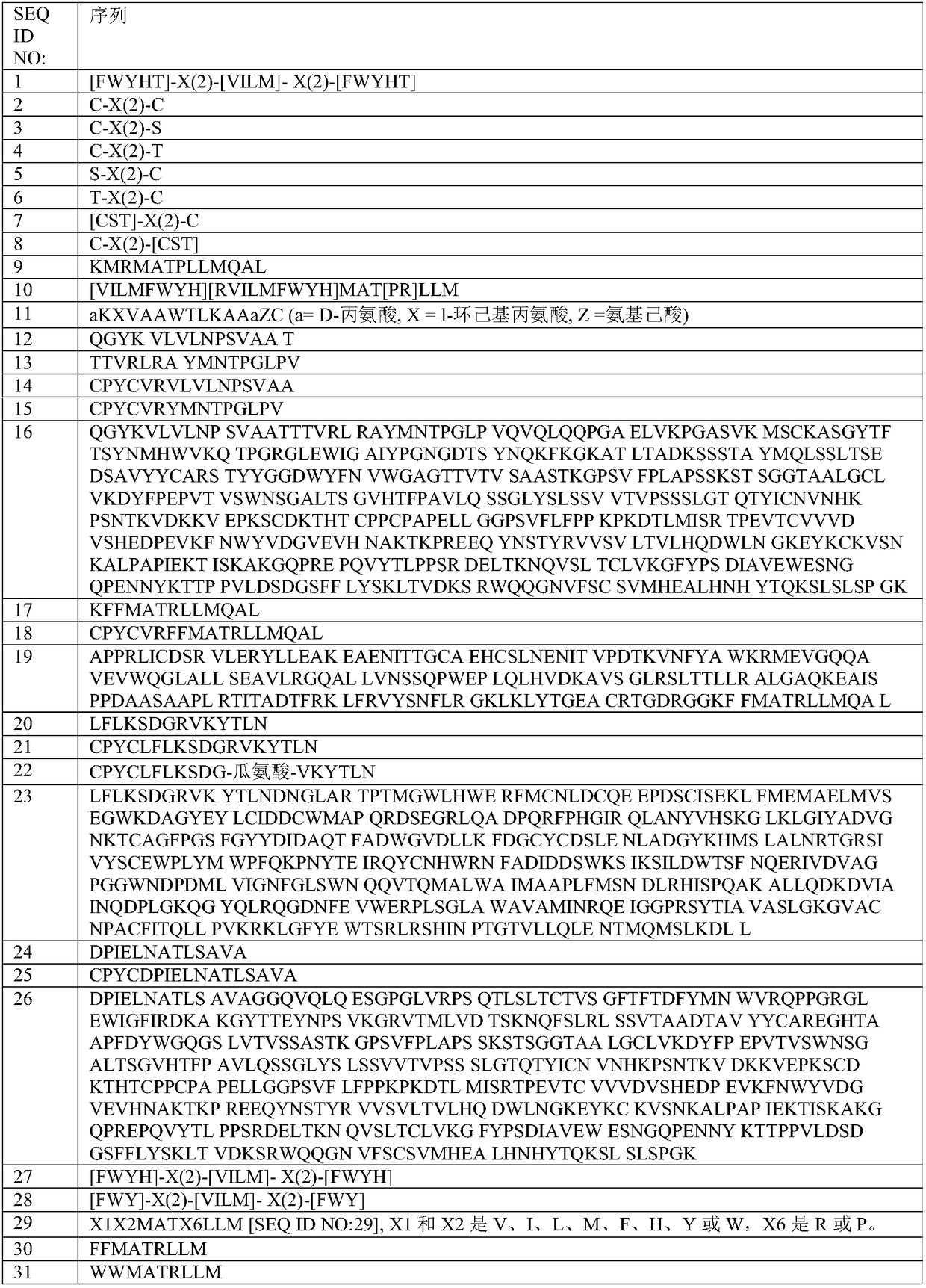

Modified soluble T cell receptor

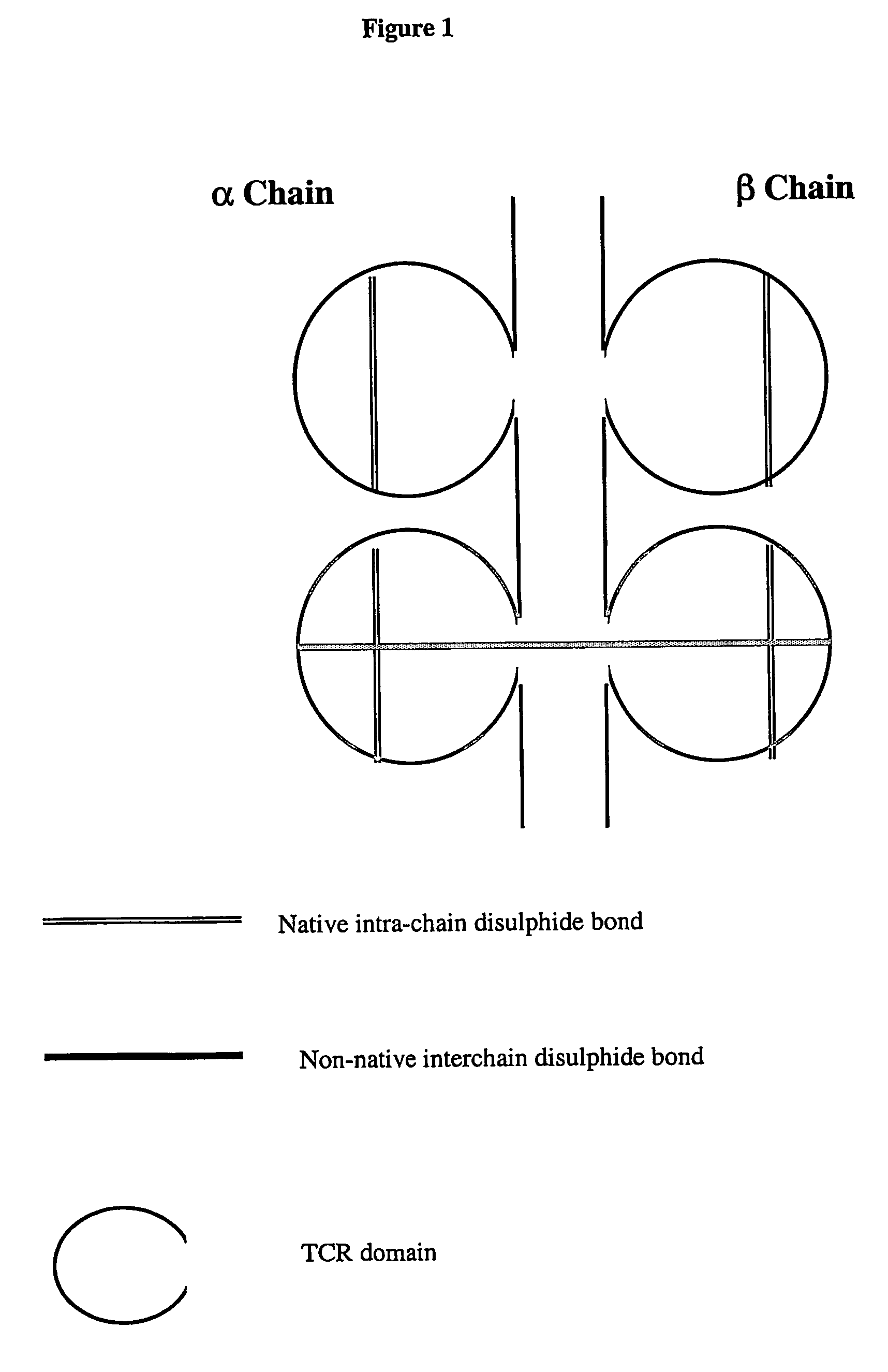

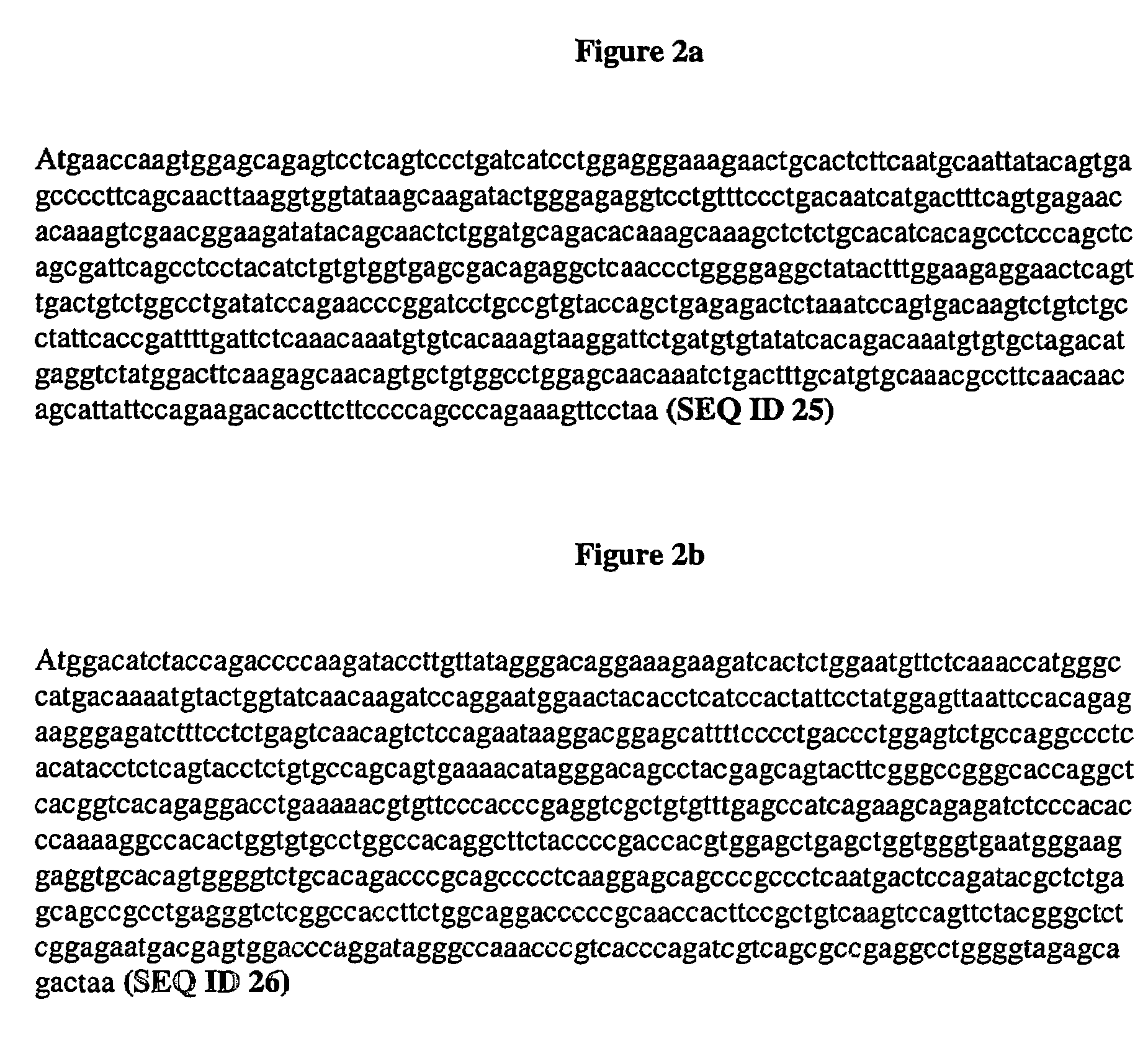

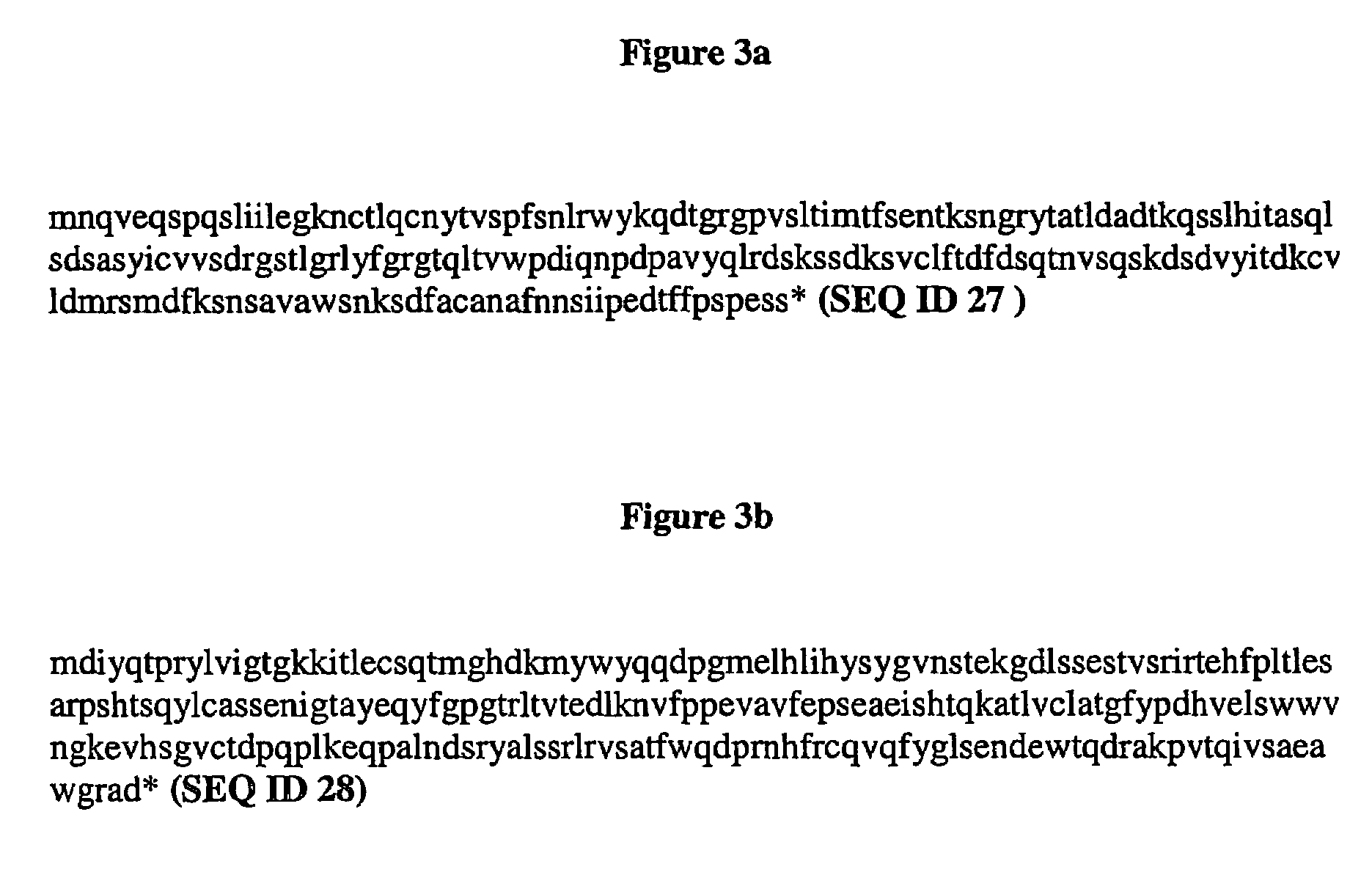

The present invention provides a soluble T cell receptor (sTCR), which comprises (i) all or part of a TCR $g(a) chain, except the transmembrane domain thereof, and (ii) all or part of a TCR $g(b) chain, except the transmembrane domain thereof. (i) and (ii) each comprise a functional variable domain and at least a part of the constant domain of the TCR chain, and are linked by a disulphide bond between constant domain residues which is not present in native TCR, characterized in that the sTCR recognizes a CD1-antigen complex, a bacterial superantigen or a peptide-MHC / superantigen complex.

Owner:IMMUNOCORE LTD +1

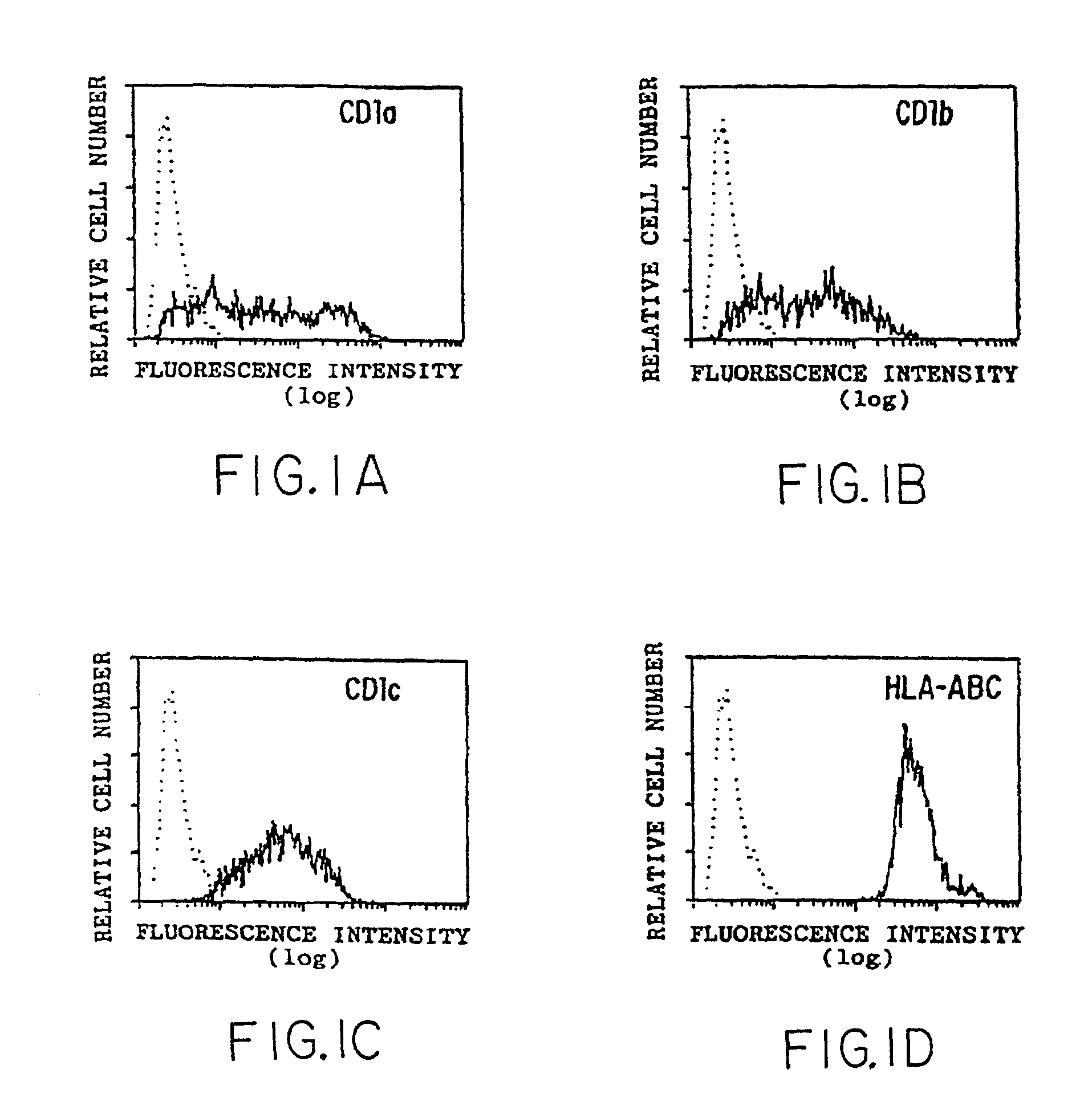

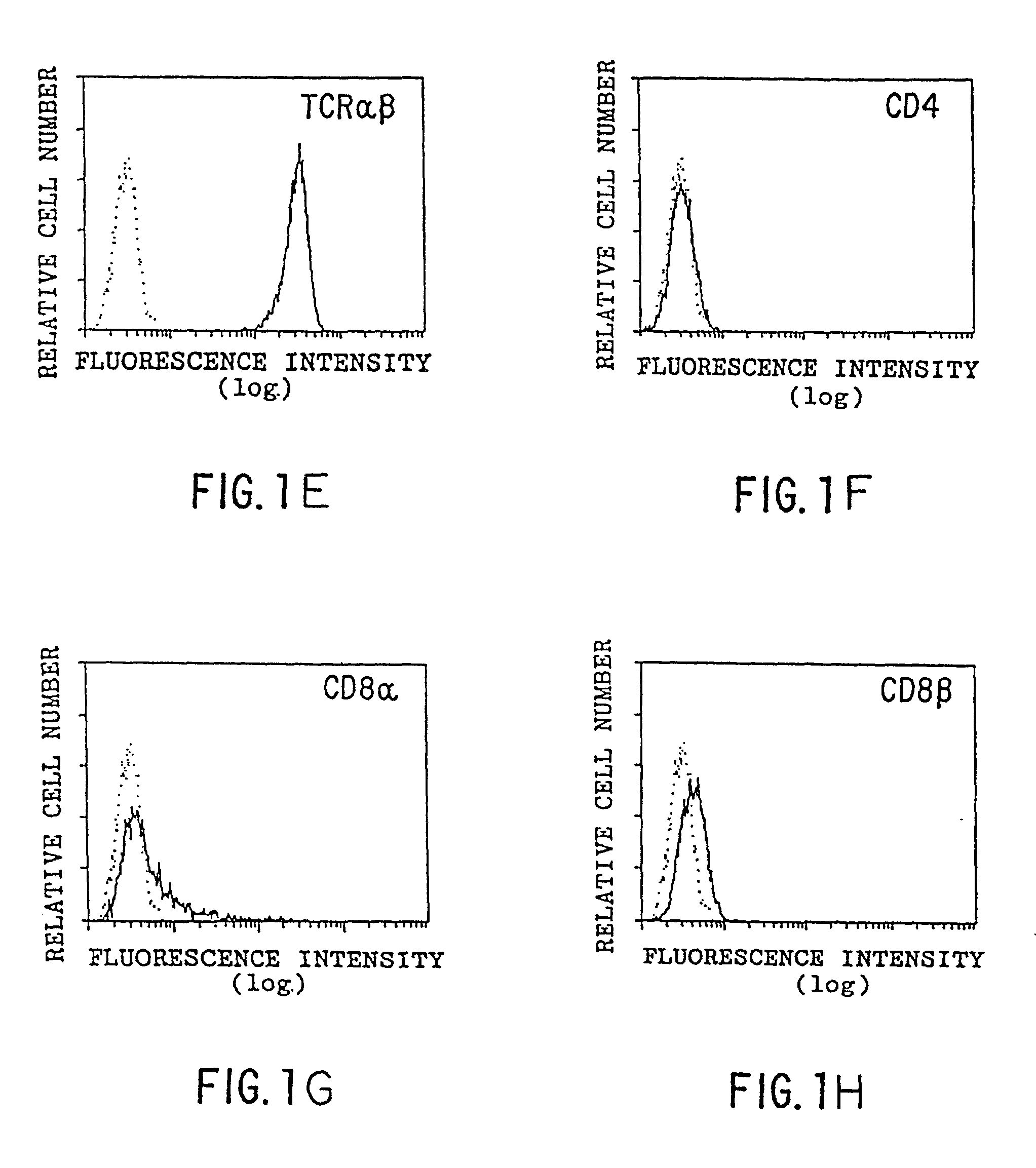

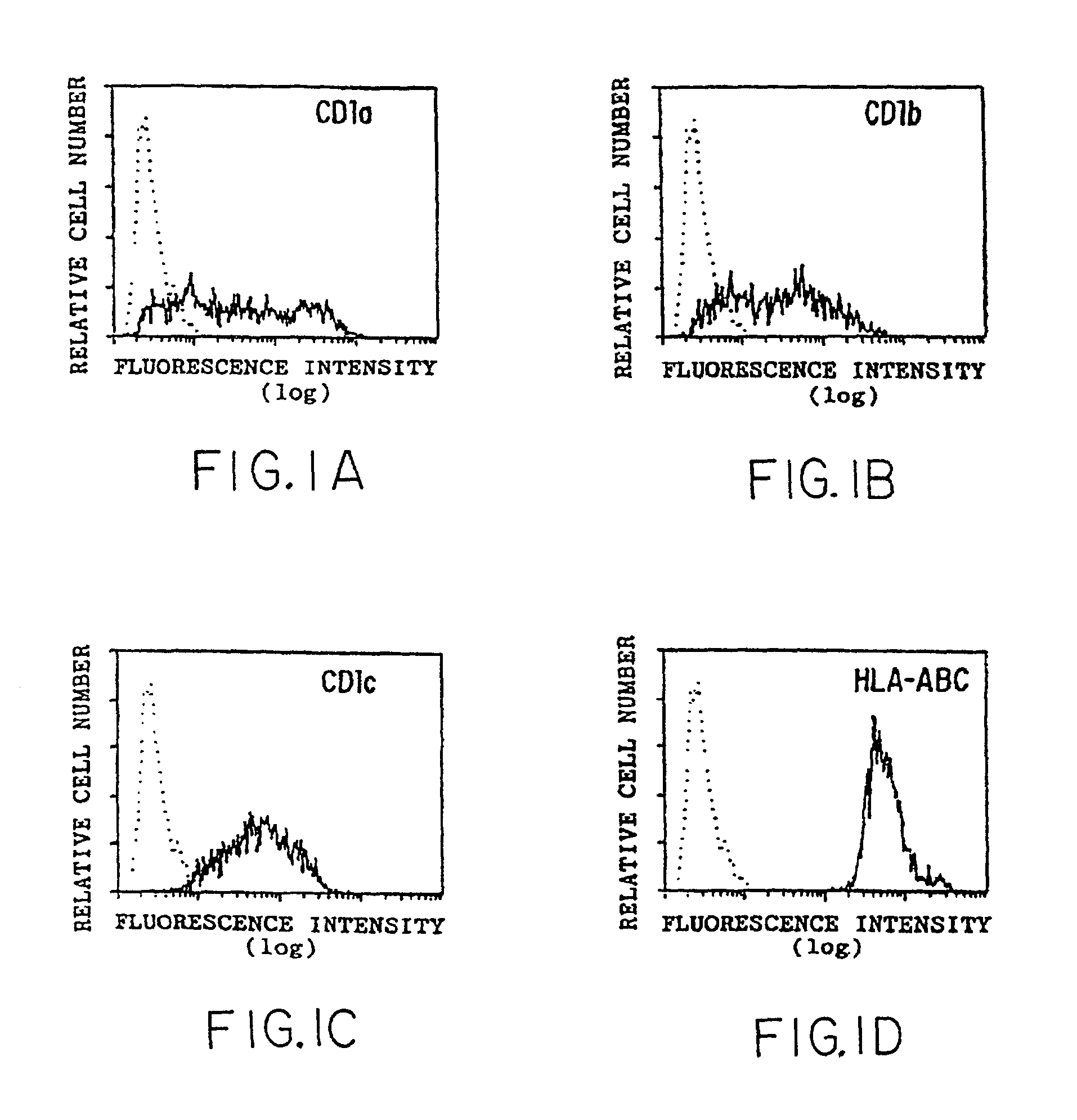

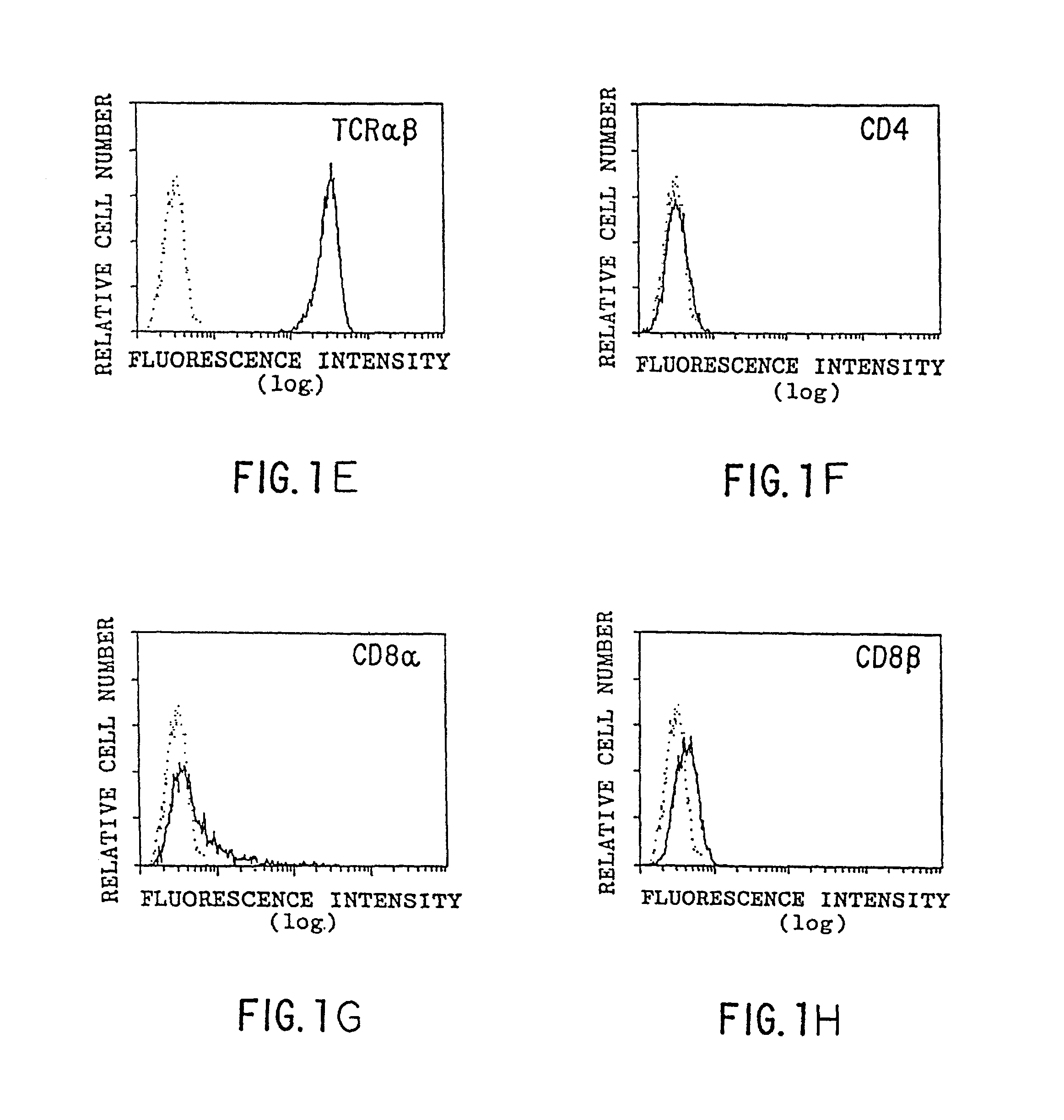

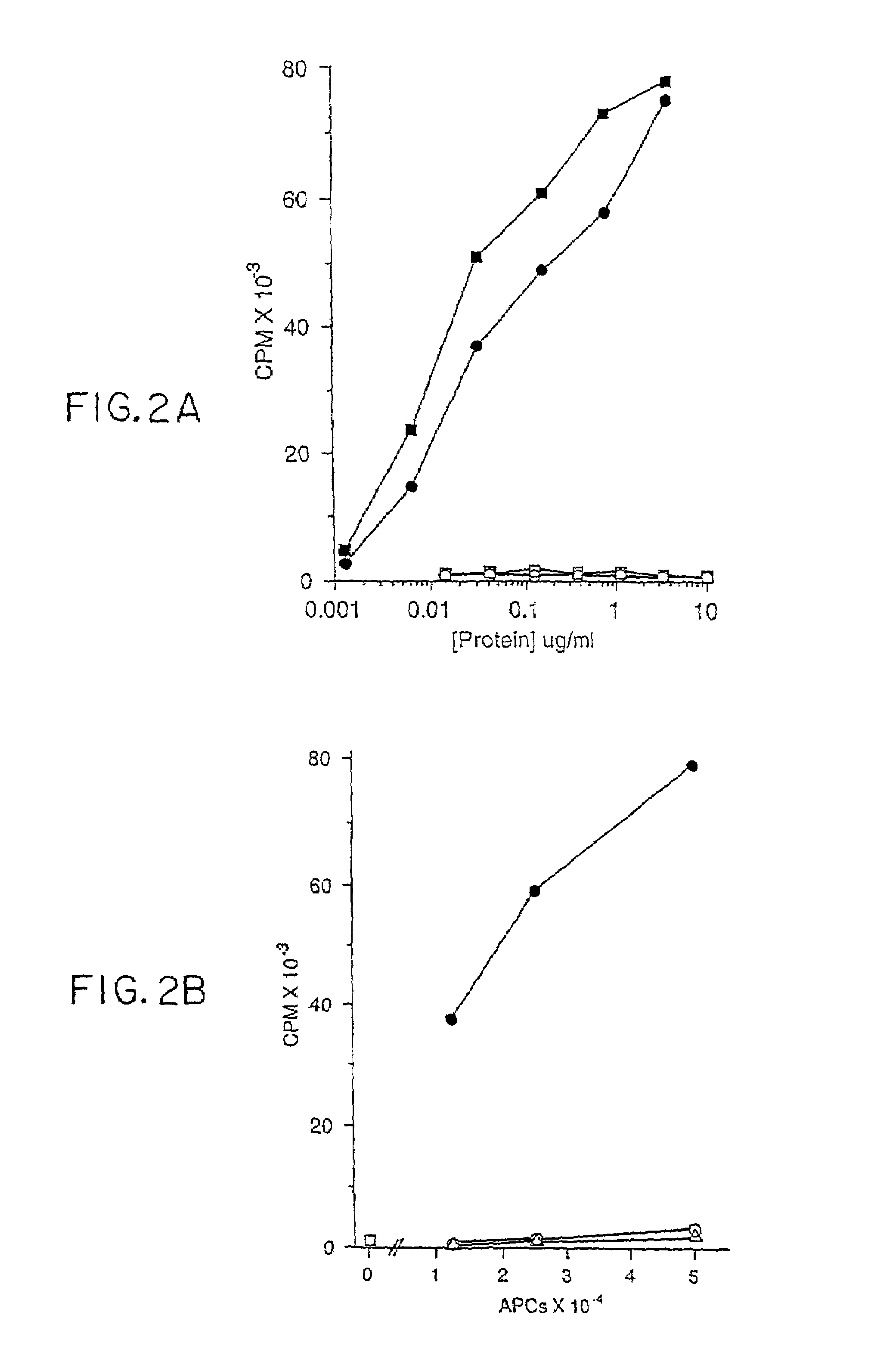

Presentation of hydrophobic antigens to T-cells by CD1 molecules

InactiveUS6238676B1Bacterial antigen ingredientsImmunoglobulins against cell receptors/antigens/surface-determinantsAntigenVaccination

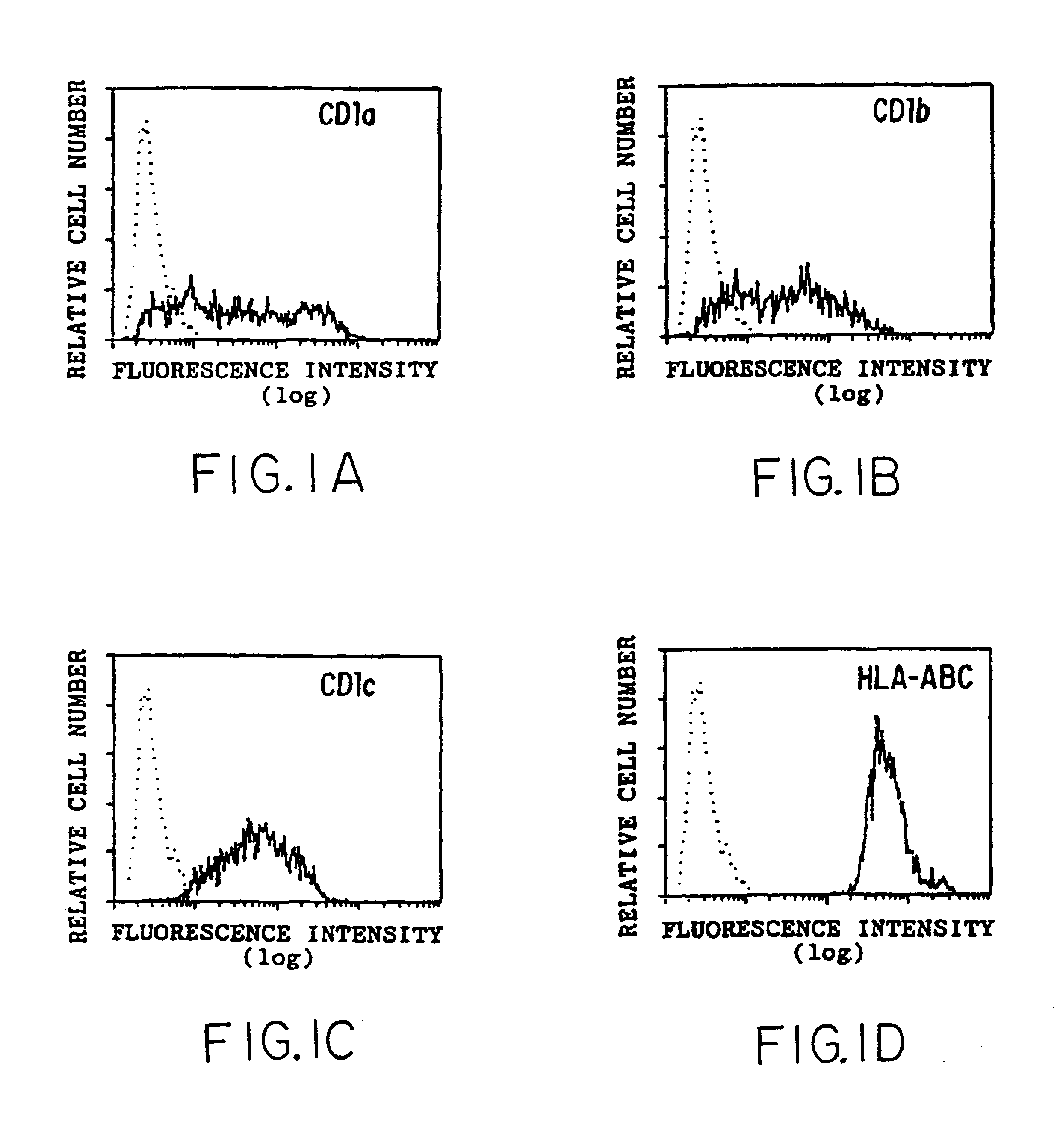

Provided are CD-1 presented antigens, compositions, cells, inhibitors and methods relating to the use of hydrophobic antigen presentation by CD1 molecules, including:methods for detecting the presence of a CD1-presented hydrophobic antigen in a sample;methods for isolating such CD1-presented antigens and the isolated antigens;vaccines containing CD1-presented antigens and vaccination methods;methods of blocking CD1 antigen presentation;methods of identifying and / or isolating CD1 blocking agents and the isolated CD1 blocking agents;methods of inducing CD1 expression; andT-cells for use in the methods disclosed.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

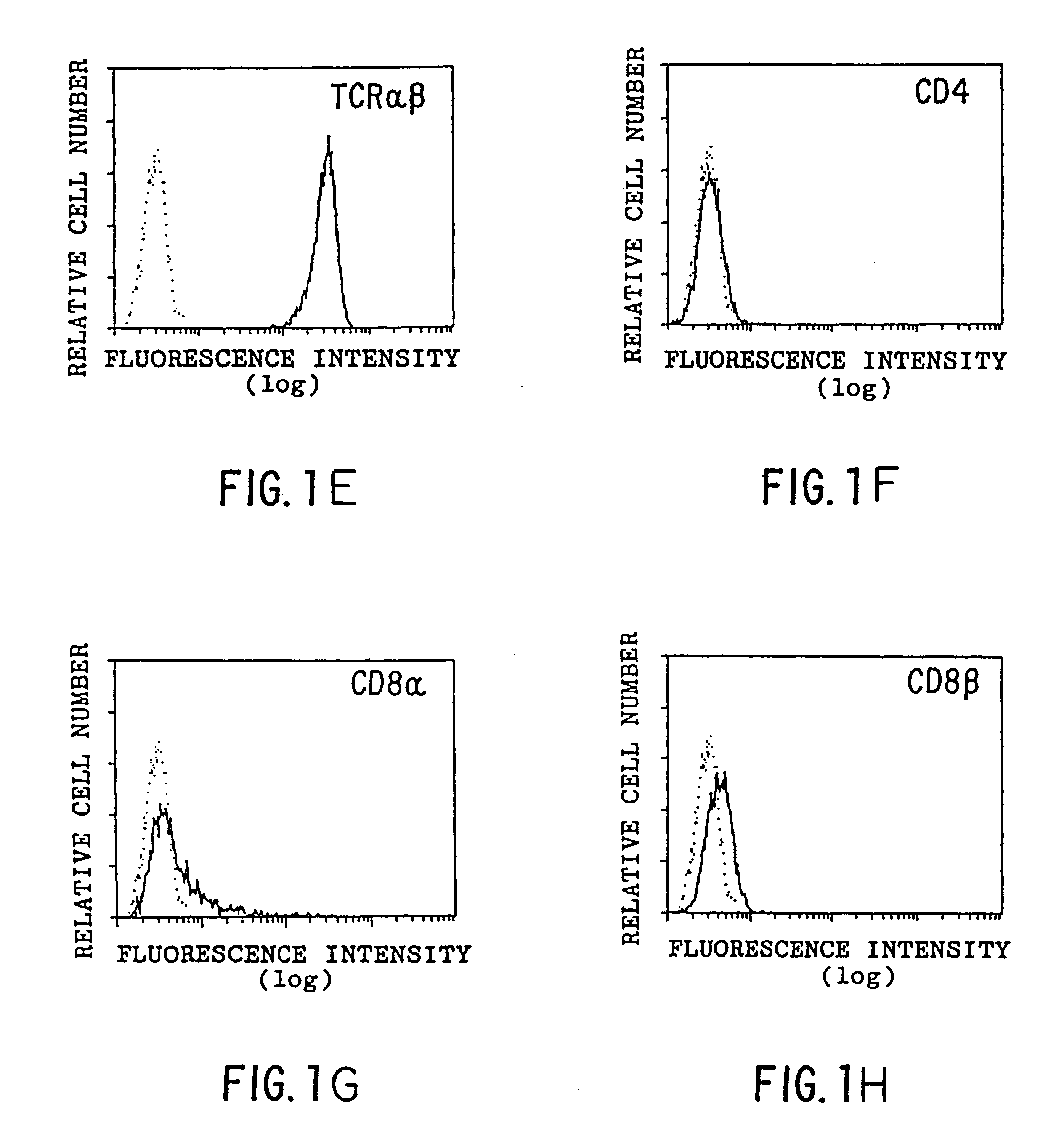

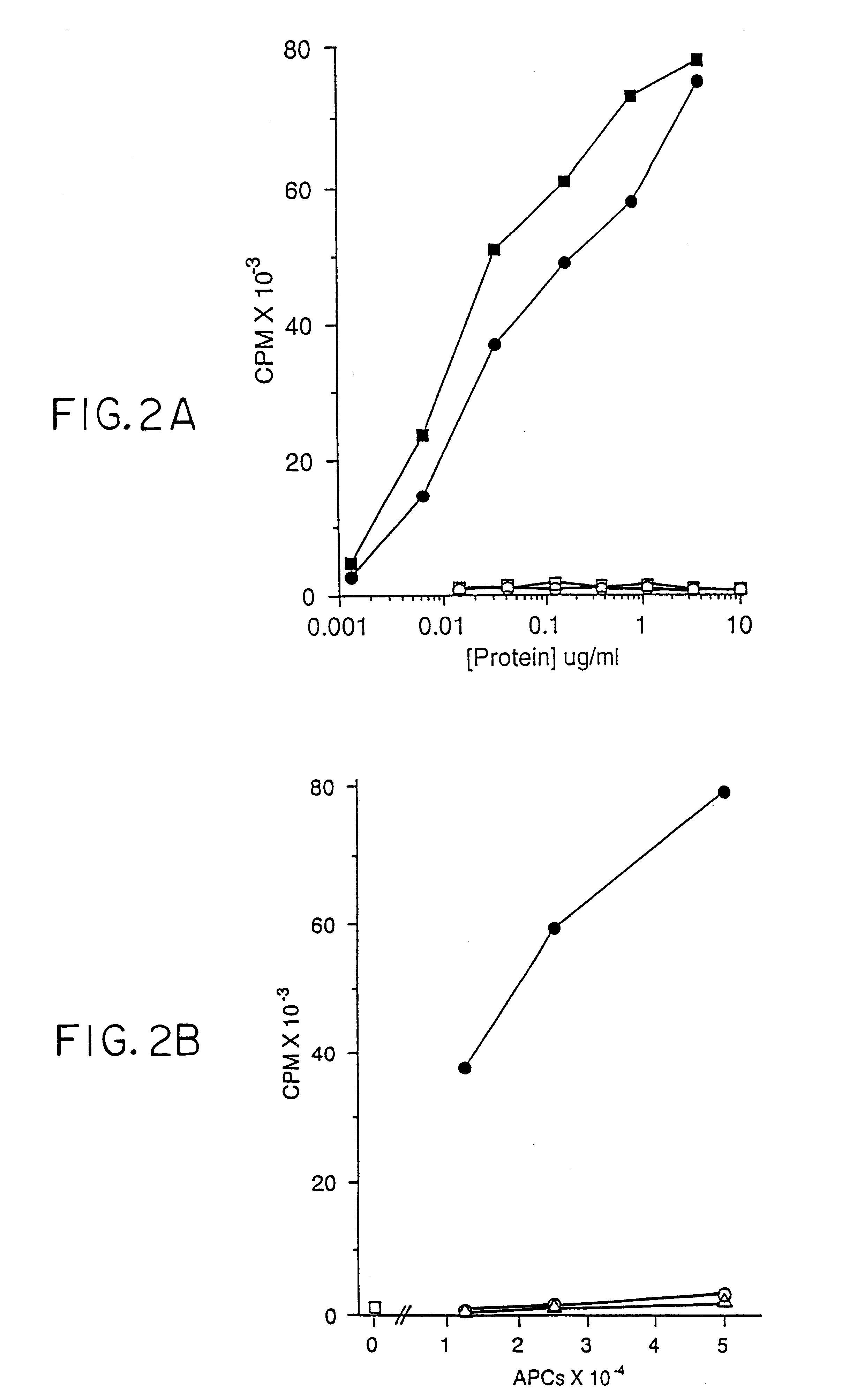

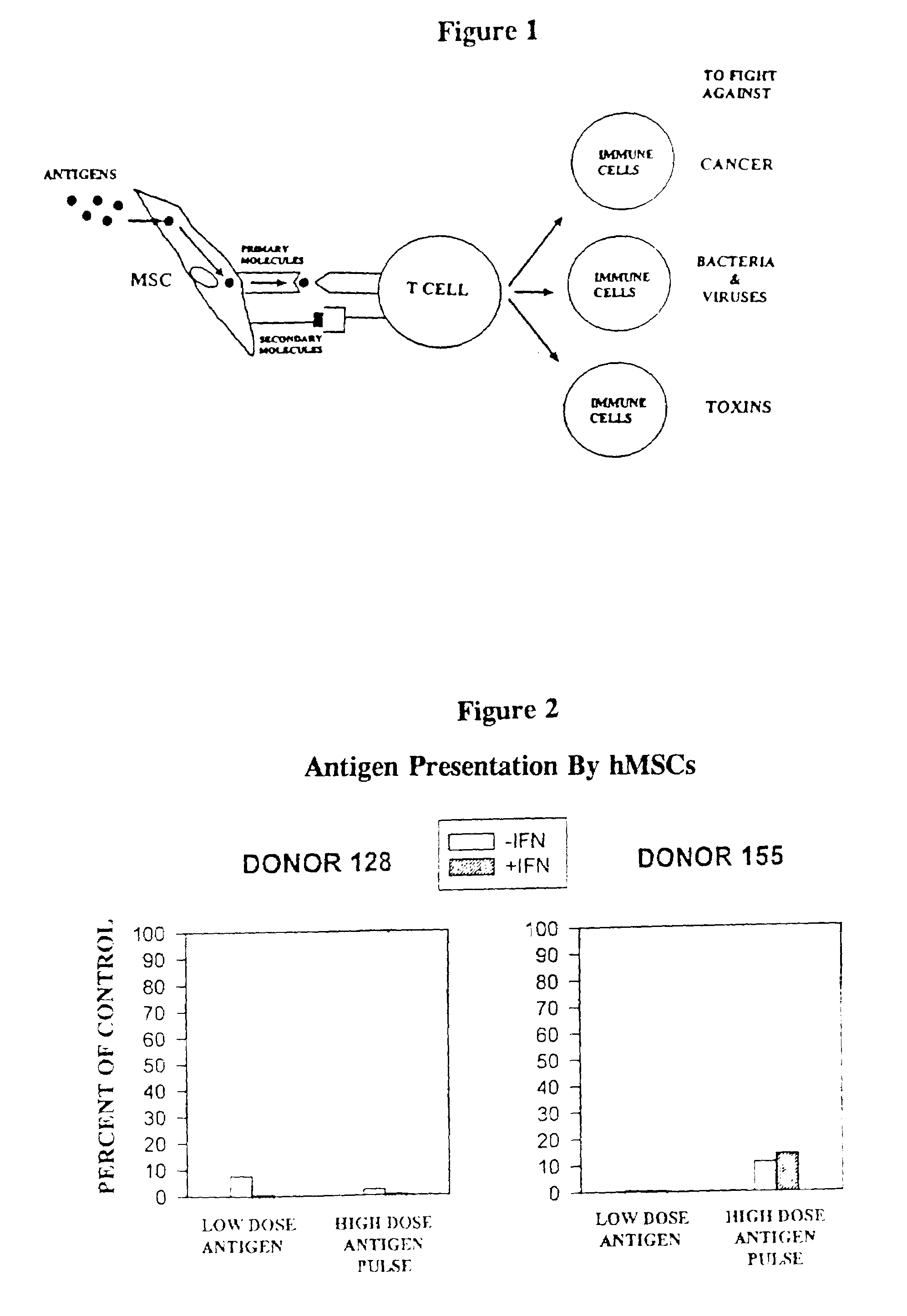

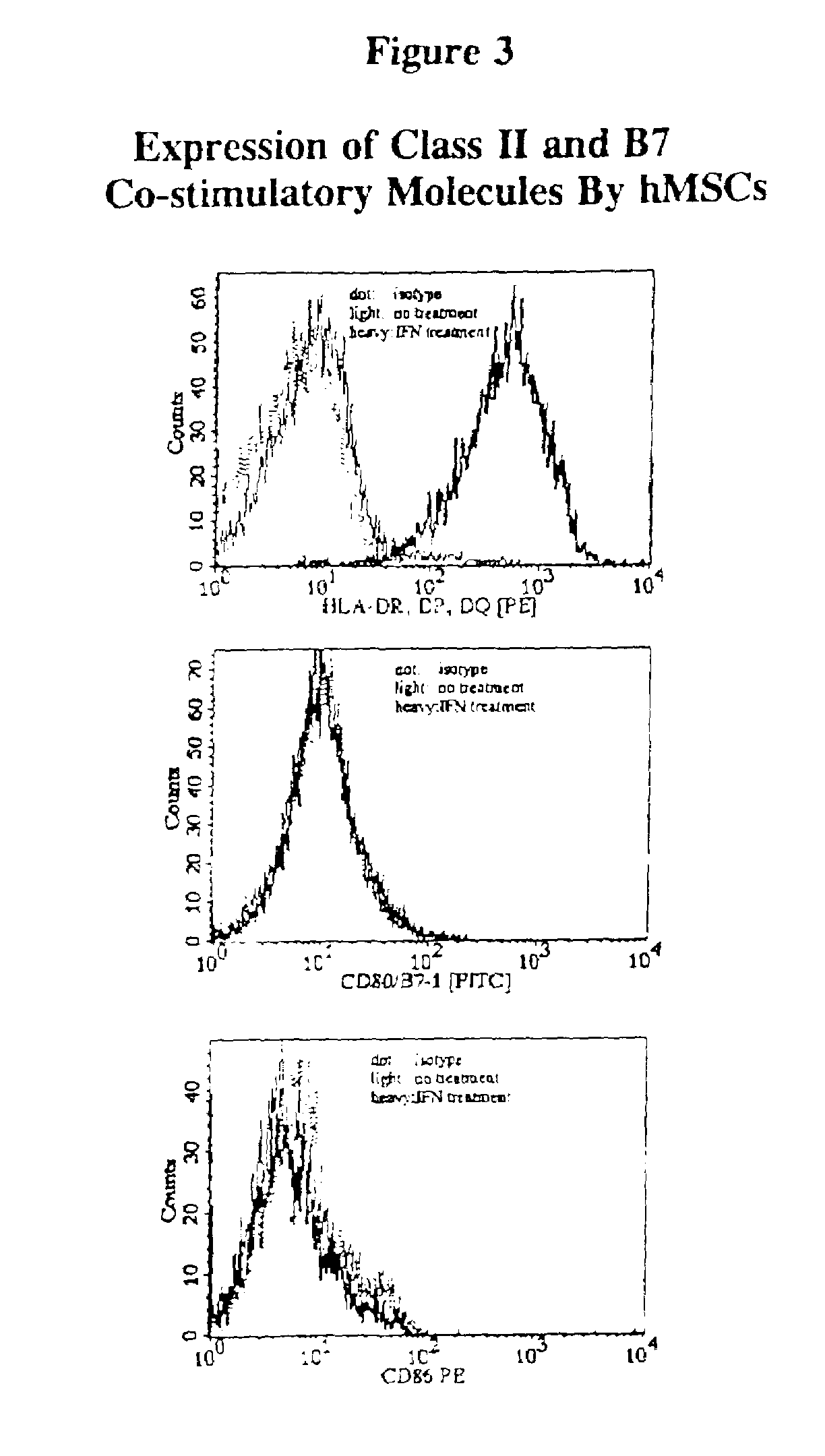

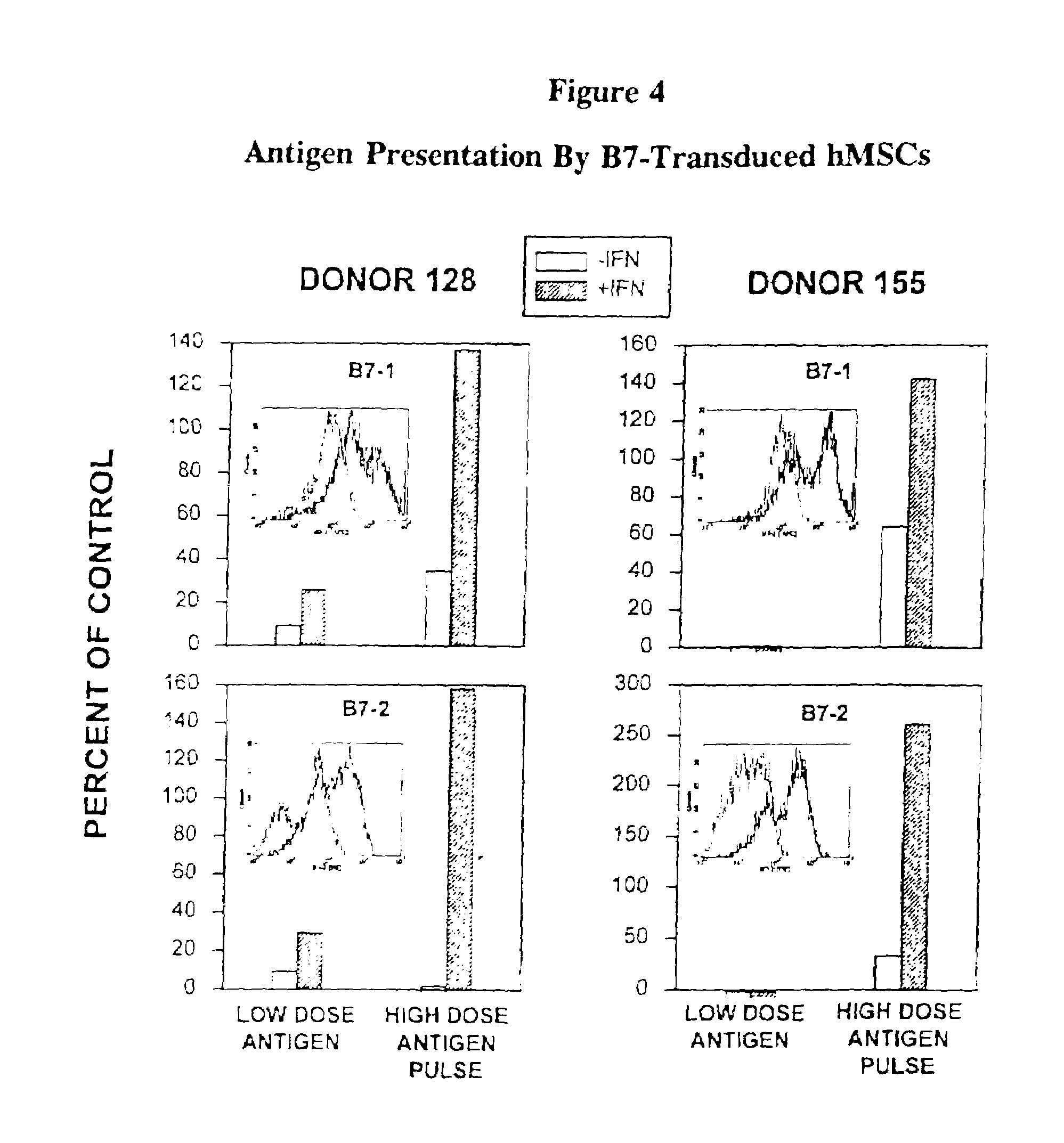

Antigen presenting mesenchymal stem cells

Disclosed is a mesenchymal stem cell and / or cell of the adipocyte lineage that (i) has been modified to have at least one exogenous antigen bound to at least one primary surface molecule of said cell such that said at least one antigen can initiate an immune response and (ii) also expresses at least one co-stimulatory molecule. The antigen is preferably a protein, polypeptide, lipid or glycolipid. The primary surface molecule is MHC I, MHC II or CD1. Also disclosed is a method for stimulating presentation of at least one exogenous antigen fragment on a mesenchymal stem cell primary surface molecule by contacting a mesenchymal stem cell that is capable of expressing at least one co-stimulatory molecule with (i) an exogenous antigen or (ii) genetic material that codes for the exogenous antigen which the mesenchymal stem cell processes into at least one antigen fragment. The method can further include contacting the mesenchymal stem cell with interferon-γ. Also disclosed are a method for determining the state of activation of a T lymphocyte population and a method for the treatment or prevention of a disease in an animal.

Owner:MESOBLAST INT

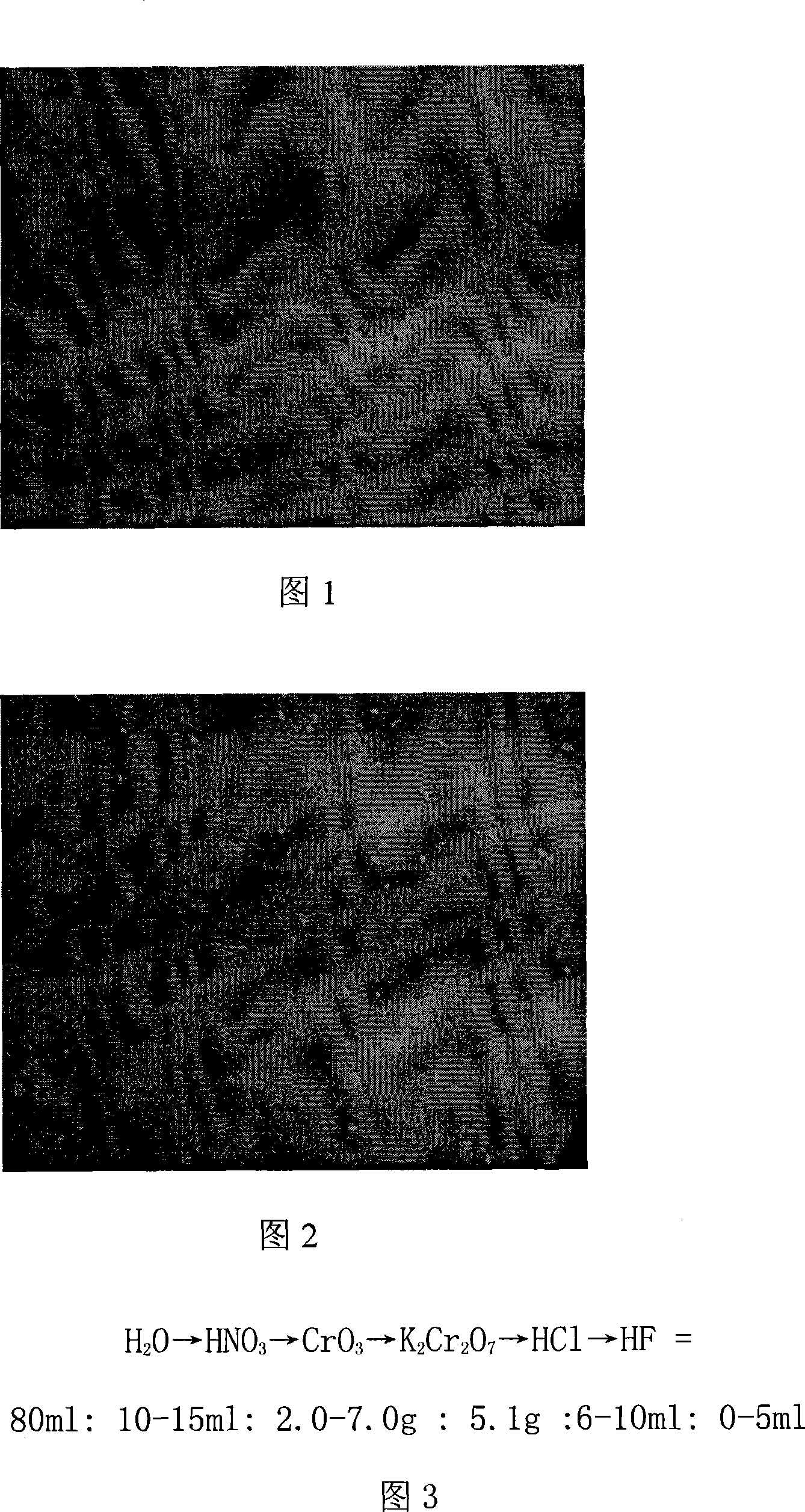

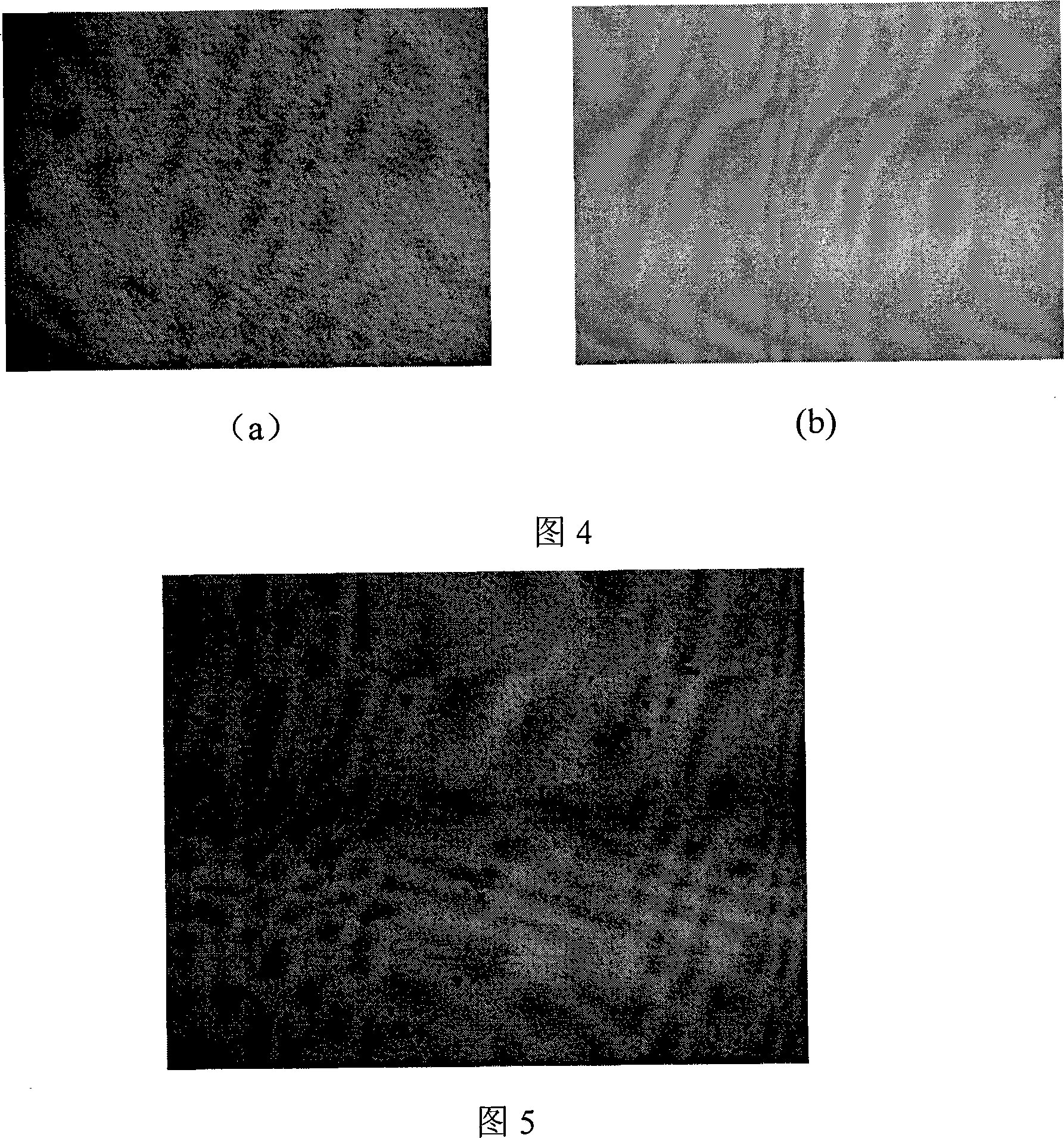

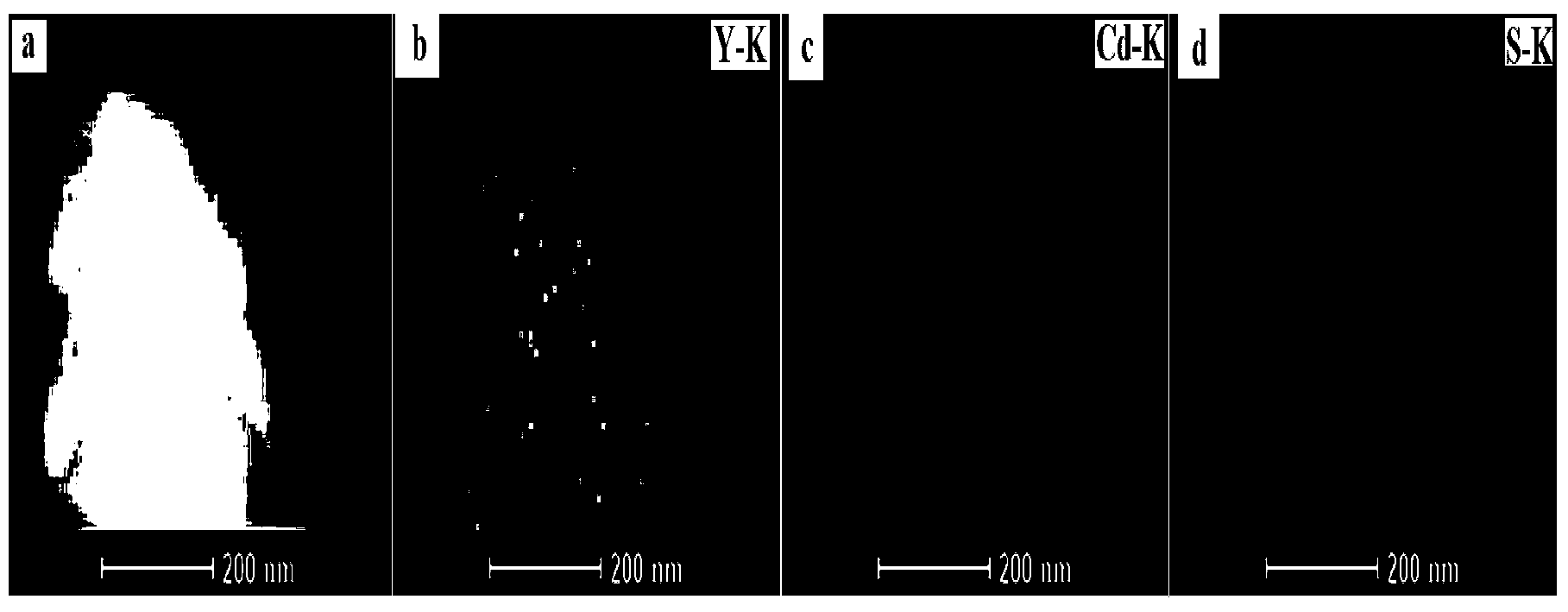

Corrosive agent and corrosion method for II-VI family semiconductor material line defect display

The invention discloses a corrosive agent which is used for showing the dislocation of II-VI group semiconductor materials and the corrosive agent is provided with the component ratio of 80ml: 6 to 10ml: 10 to 15ml: 0 to 5ml: 5.1g: 2.0 to 7.0g of H2O to HCl to HNO 3 to HF to K2Cr2O7 to CrO3; wherein, the II-VI group semiconductor materials are ZnyCd1-yTe materials and Hg1-xCdxTe thin film materials which develop by taking the ZnyCd1-yTe materials as the substrate extension; the corrosion method comprises the pretreatment of the eroded samples, the dislocation erosion and the post treatment of the eroded samples; compared with two present common Schaake and Chen corrosive agents specially used for showing the dislocation of the Hg1-xCdxTe thin film materials, the invention has the advantages of bigger shape of a corrosive pit and clear rules and background, and showing the dislocation corrosive pit of the substrate materials Cd1-yZnyTe, which has great significance in the study of the dislocation corresponding relations of the extension and the substrate.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Presentation of hydrophobic antigens to T-cells by CD1 molecules

Provided are CD-1 presented antigens, compositions, cells, inhibitors and methods relating to the use of hydrophobic antigen presentation by CD1 molecules, including: methods for detecting the presence of a CD1-presented hydrophobic antigen in a sample; methods for isolating such CD1-presented antigens and the isolated antigens; vaccines containing CD1-presented antigens and vaccination methods; methods of blocking CD1 antigen presentation; methods of identifying and / or isolating CD1 blocking agents and the isolated CD1 blocking agents; methods of inducing CD1 expression; and T-cells for use in the methods disclosed herein.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

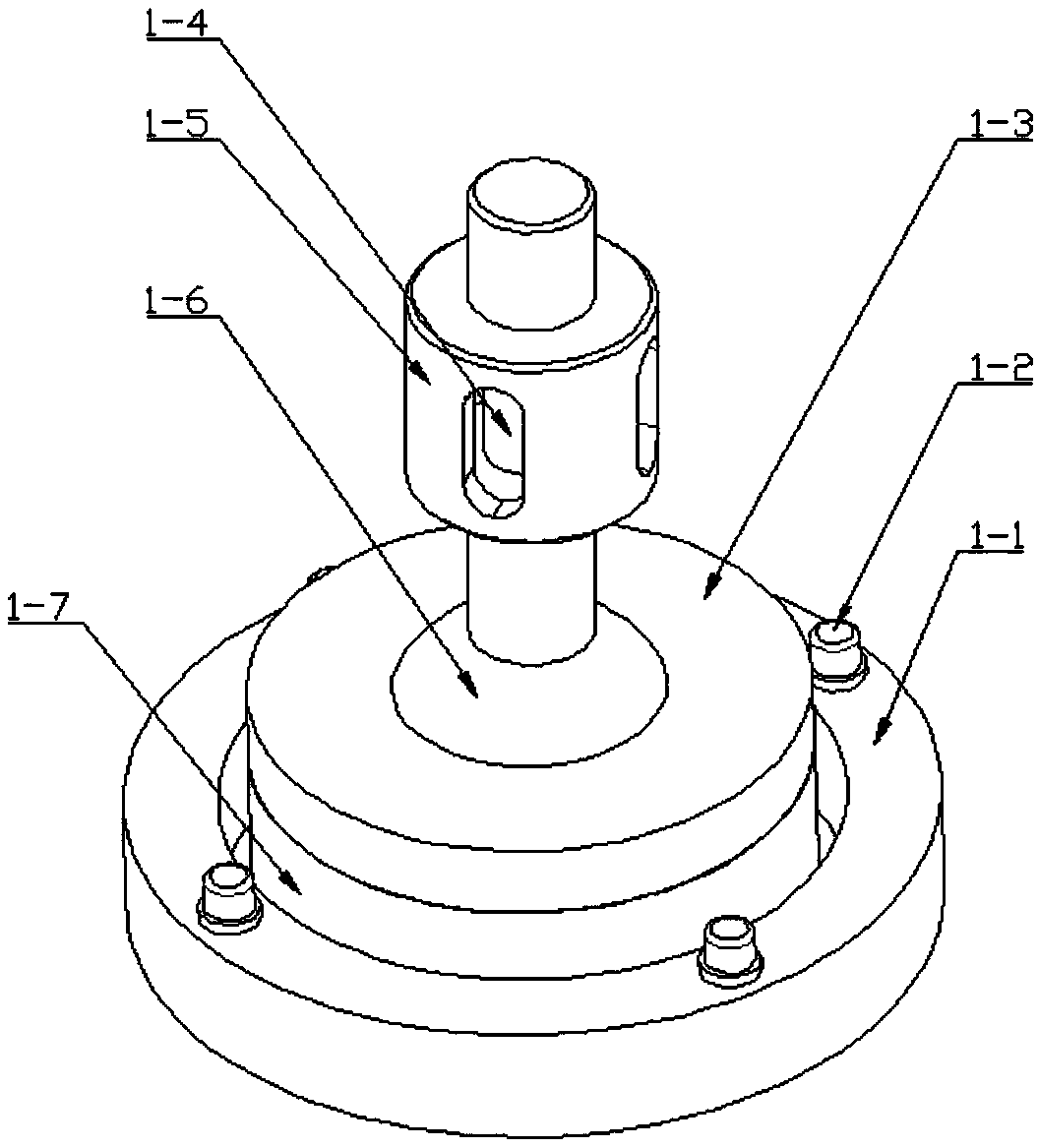

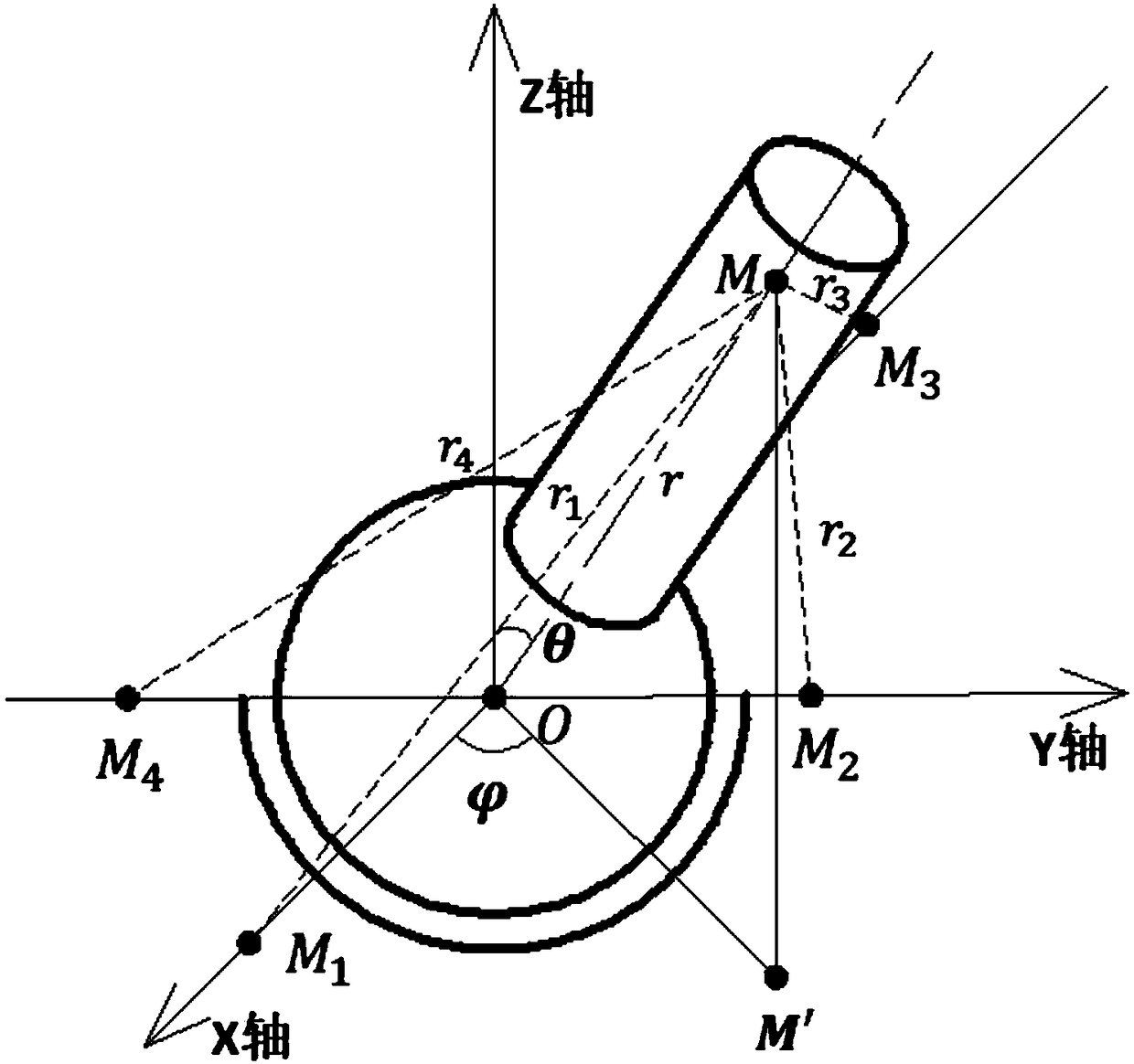

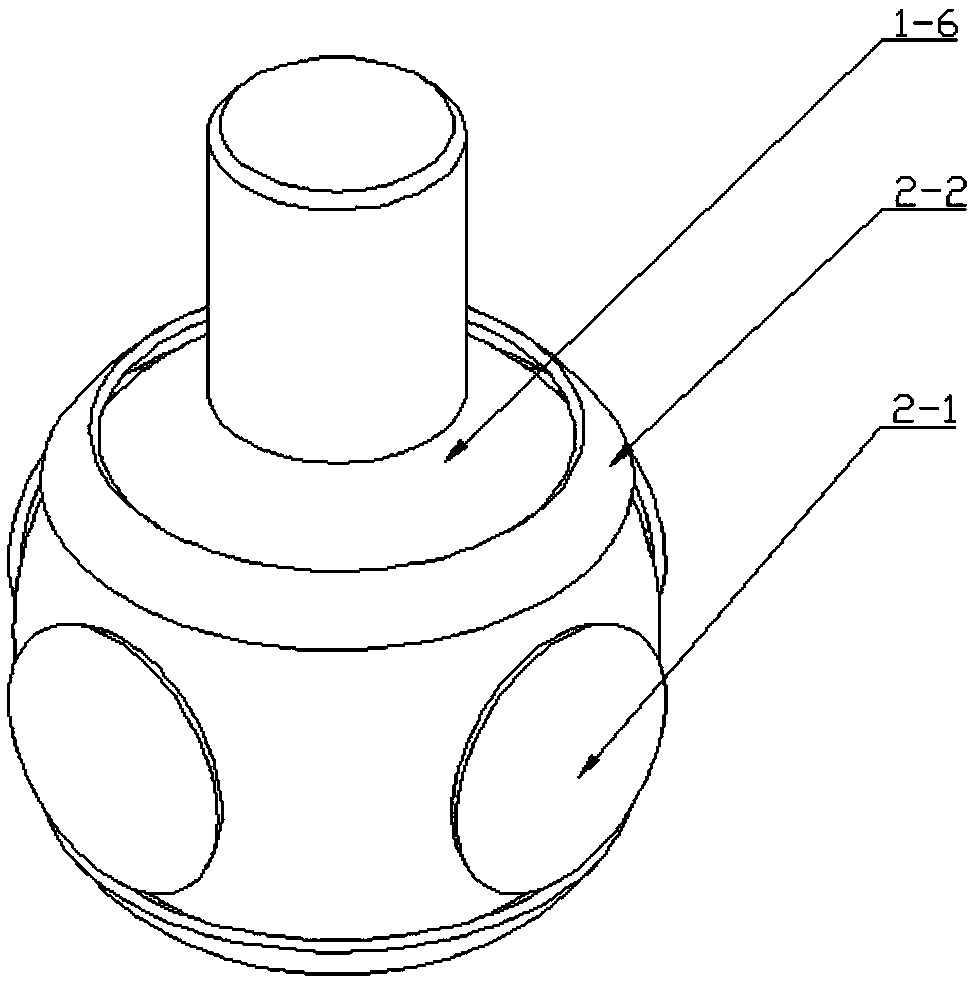

Method for simultaneously detecting precise ball hinge ball-head eccentricity and ball arm space attitude

ActiveCN109211152ARealize real-time detectionRealize non-contact detectionUsing subsonic/sonic/ultrasonic vibration meansUsing electrical meansCapacitanceEngineering

The invention discloses a method for simultaneously detecting precise ball hinge ball-head eccentricity and ball arm space attitude. At present, the method for effectively measuring ball hinge ball-head eccentricity and ball arm space attitude is few. The method comprises the following steps: acquiring distance between an emitting point of an ultrasonic emitter and a receiving point of each of four ultrasonic receivers, decoupling an included angle between a bar arm central axis and an Z axle and the included angle between a projection line of the bar arm central axis on an XOY plane and a X axle through a geometric principle; detecting capacitance CG1 of a spherical-crown electrode G1 and the capacitance CG3 of the spherical-crown electrode G3 to obtain the differential capacitance therebetween; detecting capacitance CG2 of a spherical-crown electrode G2 and the capacitance CG4 of the spherical-crown electrode G4 to obtain the differential capacitance therebetween; detecting the capacitance CD1 of the spherical-crown electrode D1 and the capacitance C2 of the spherical-crown electrode D2 to obtain the differential capacitance therebetween; and obtaining X, Y and Z values of the ball eccentricity. The ball arm space attitude of the ball hinge is acquired in real time based on the ultrasonic ranging principle, and the eccentricity of ball head of the ball hinge ball-head can beaccurately acquired based on the spherical capacitance principle.

Owner:HANGZHOU DIANZI UNIV

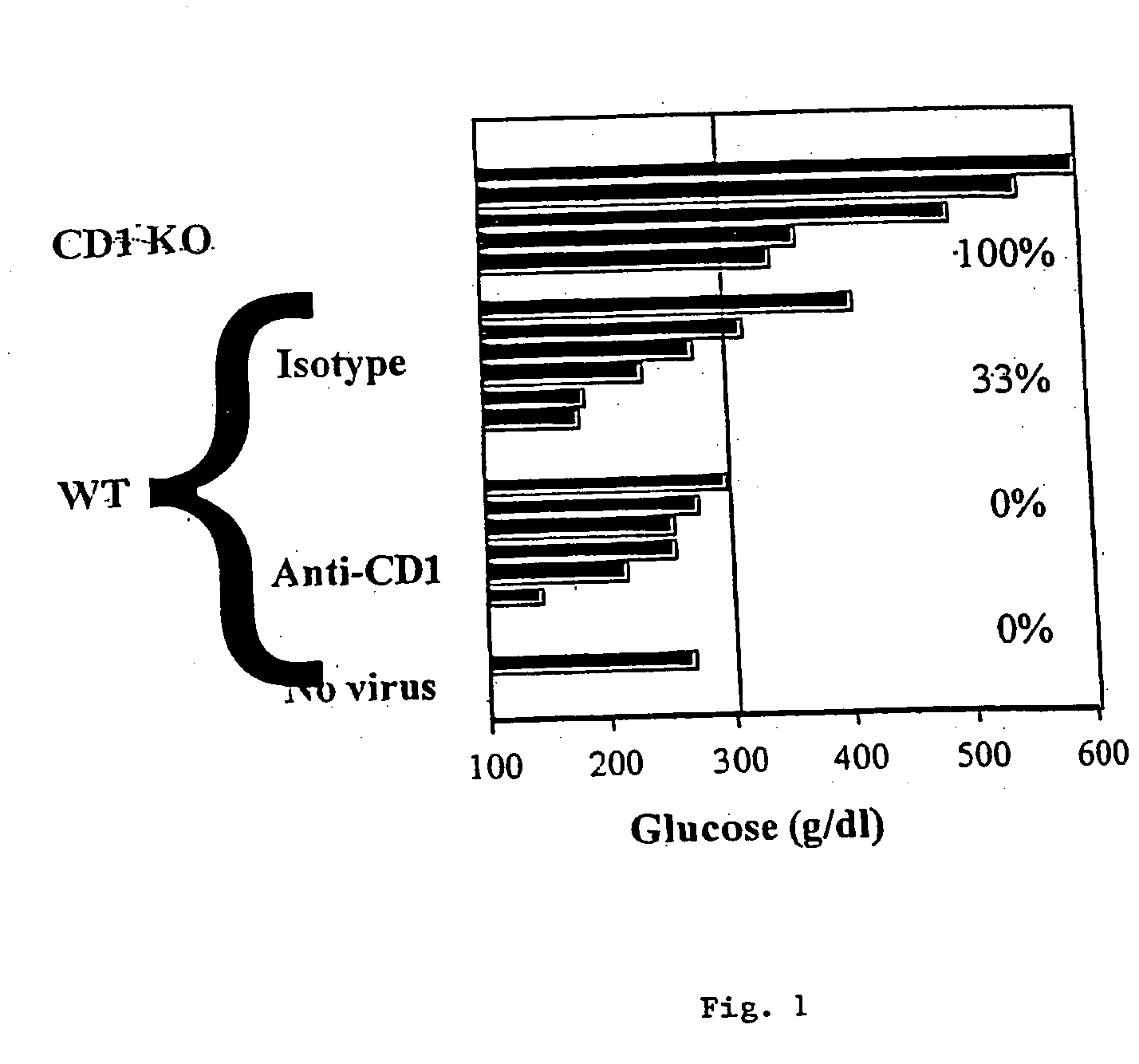

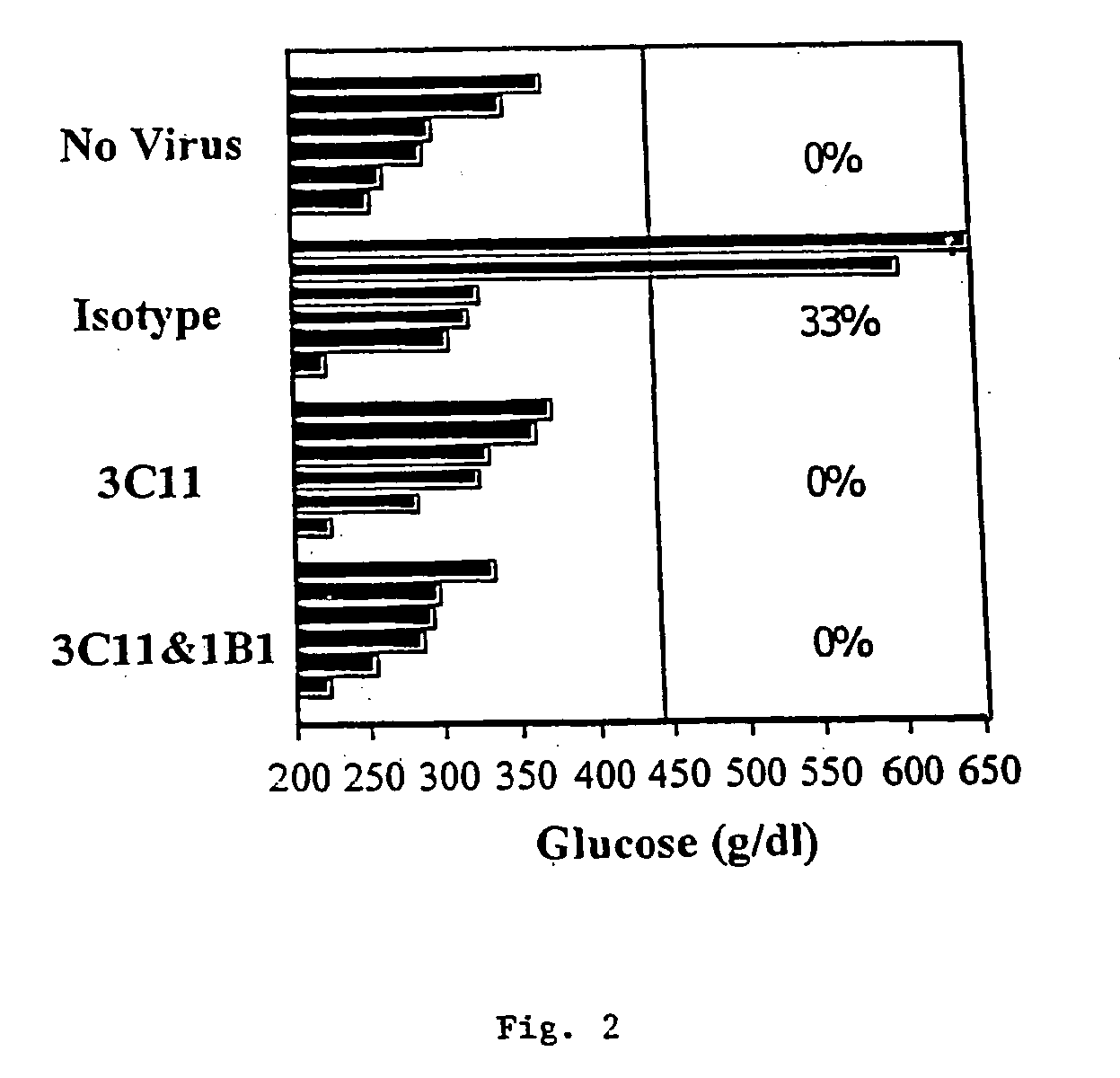

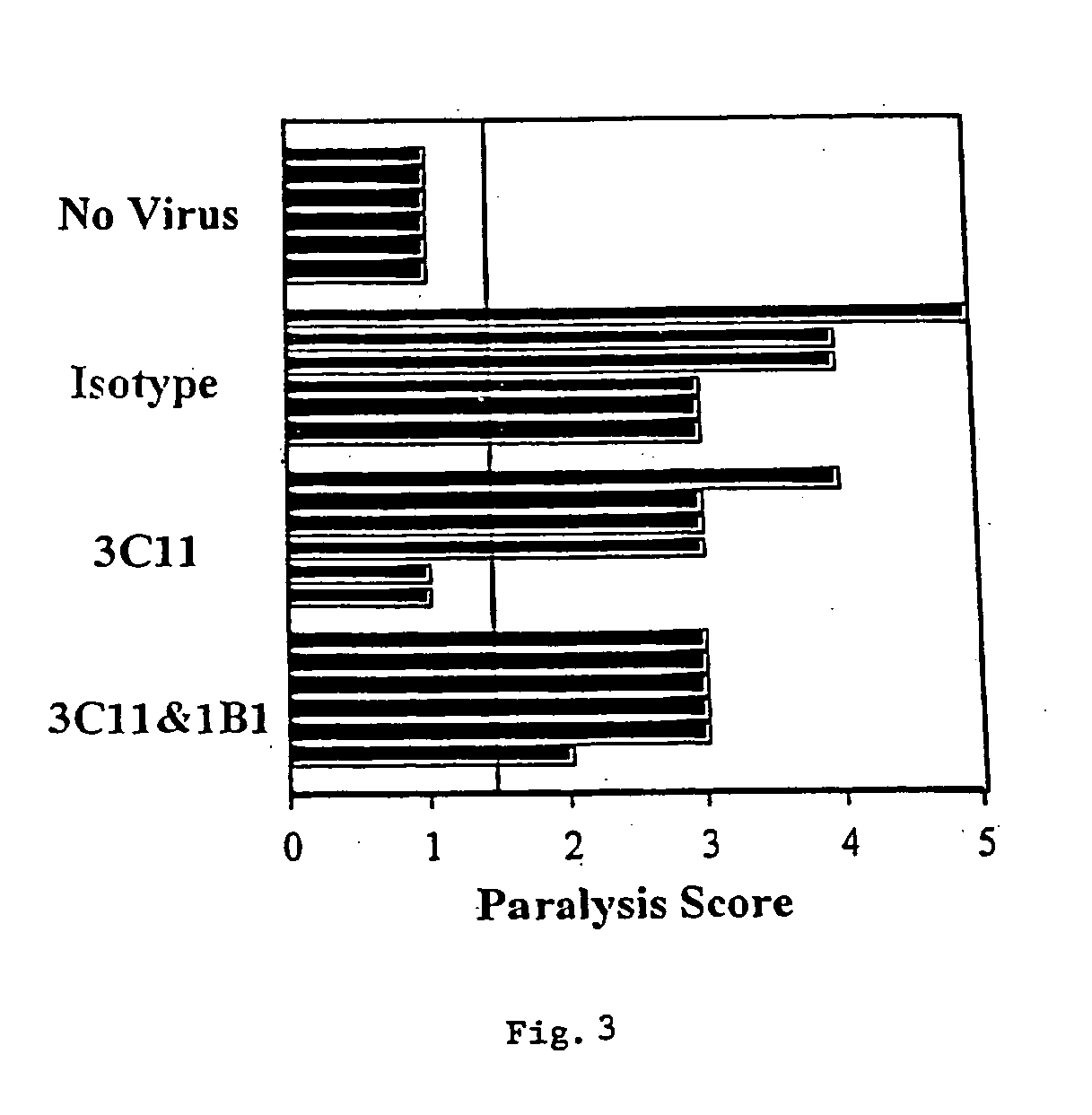

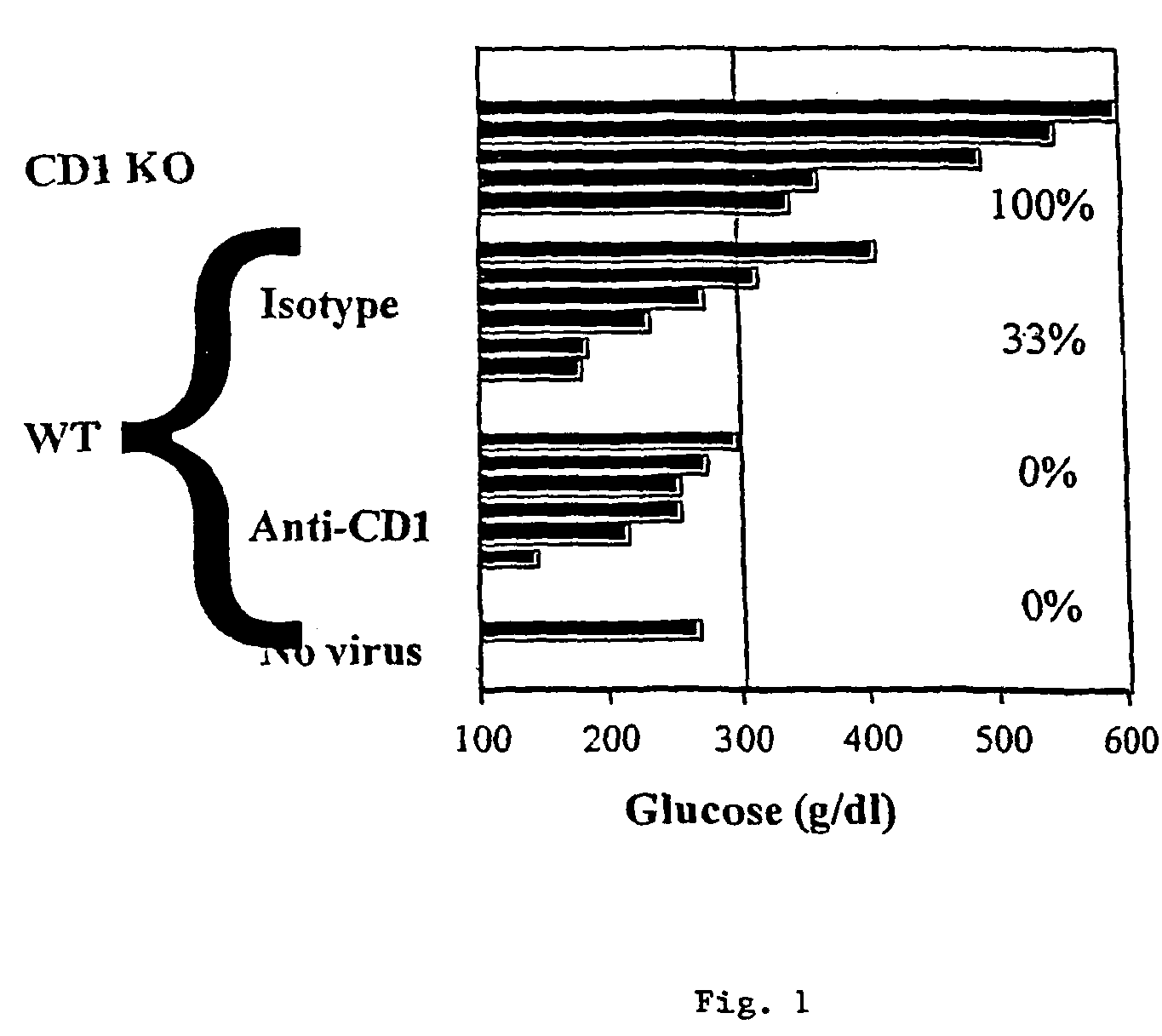

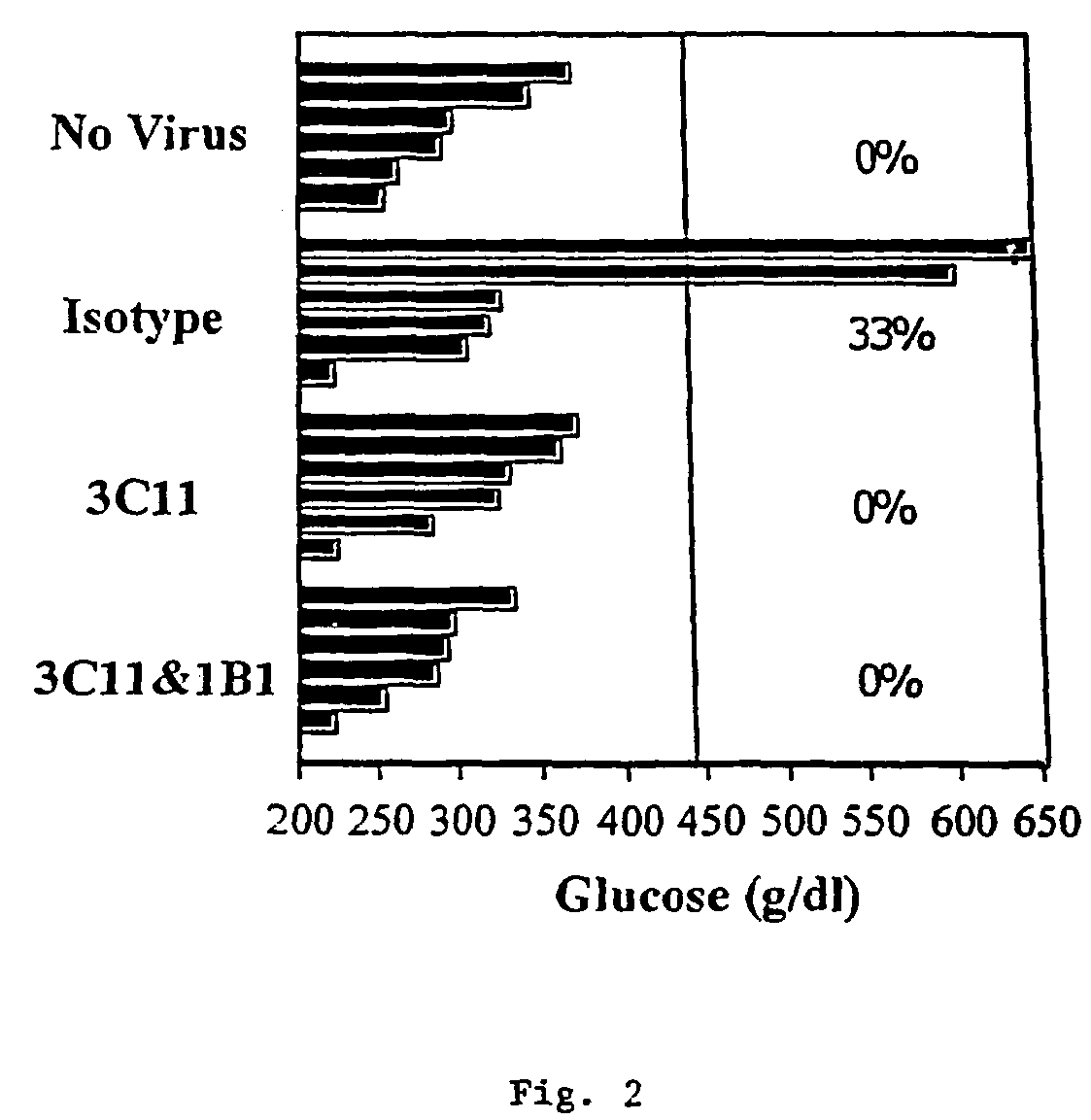

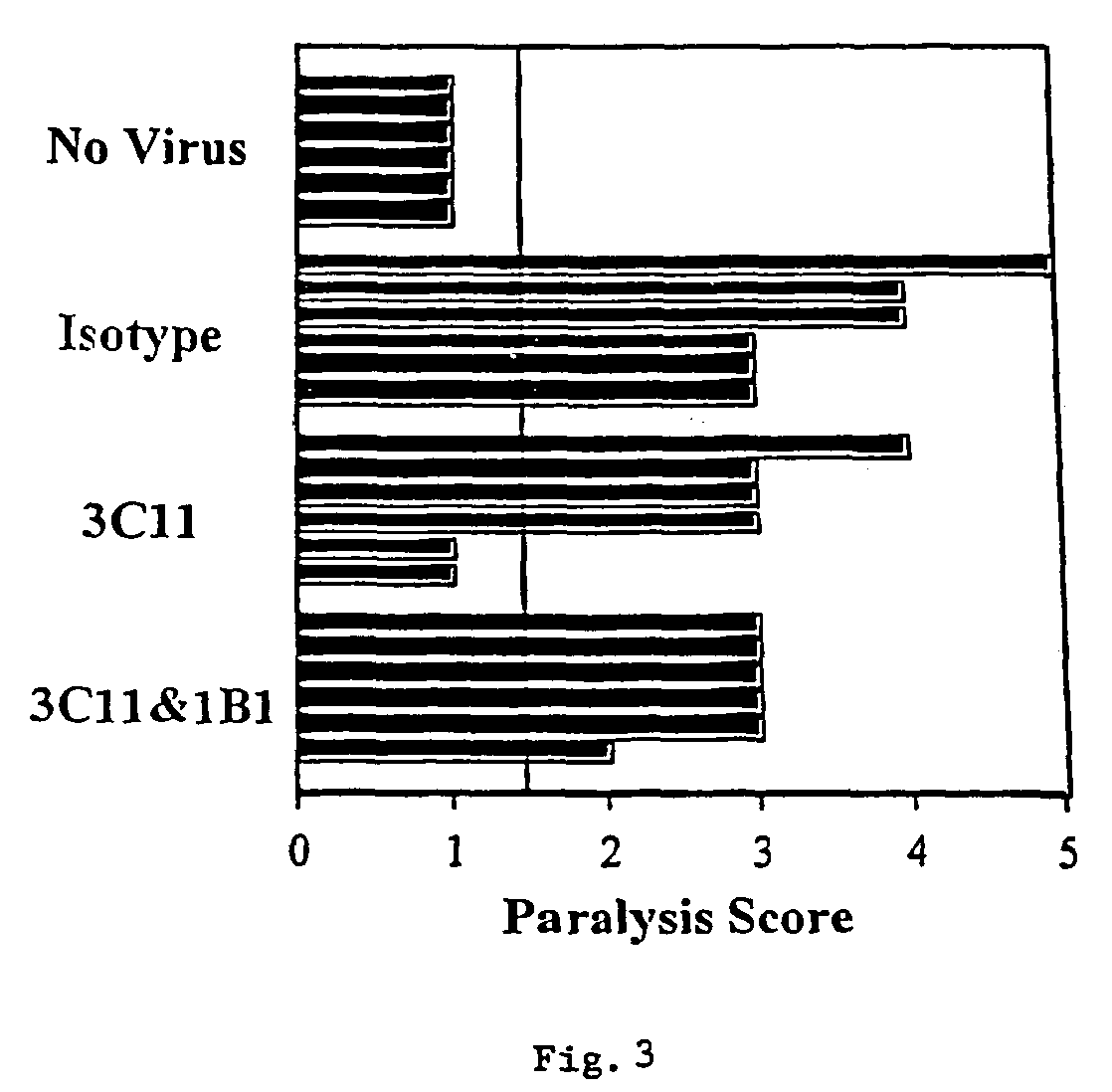

Use of anti-cd1 antibodies for the modulation of immune responses

InactiveUS20060002927A1Simple procedureEliminate requirementsAntibacterial agentsNervous disorderAutoimmune conditionImmunodeficiency disease

The invention provides methods for the administration of an anti-CD 1 antibody for the treatment or prevention of a variety of disorders, such as autoimmune disease, viral infection, bacterial infection, parasitic infection, infection by a eukaryotic pathogen, allergy, asthma, inflammatory condition, graft versus host disease, graft rejection, immunodeficiency disease, spontaneous abortion, pregnancy, and cancer.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

Presentation of hydrophobic antigens to T-cells by CD1 molecules

Provided are CD-1 presented antigens, compositions, cells, inhibitors and methods relating to the use of hydrophobic antigen presentation by CD1 molecules, including: methods for detecting the presence of a CD1-presented hydrophobic antigen in a sample; methods for isolating such CD1-presented antigens and isolated antigens; vaccines containing CD1-presented antigens and vaccination methods; methods of blocking CD1 antigen presentation; methods of identifying and / or isolating CD1 blocking agents and the isolated CD1 blocking agents; methods of inducing CD1 expression; and T-cells for use in the methods disclosed herein.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

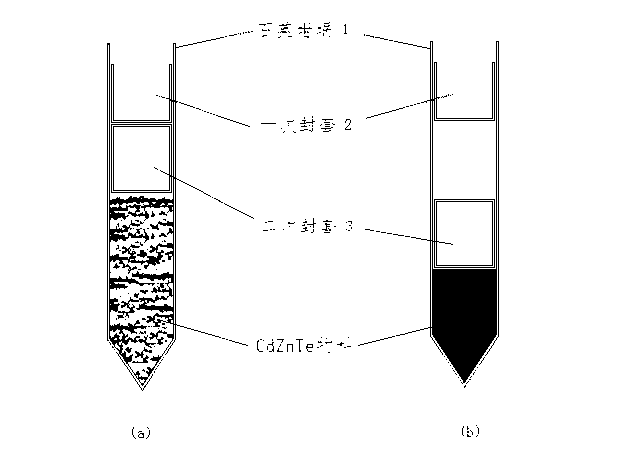

Method and device for compressing free space in cadmium zinc telluride crystal growing crucible through double sealing sleeves

InactiveCN102703983AAchieve compressionAfter-treatment apparatusPolycrystalline material growthVacuum pumpingRoom temperature

The invention relates to a method and a device for compressing a free space in a cadmium zinc telluride crystal growing crucible through double sealing sleeves and belongs to the technical field of special crystal growth. The method has the main technical scheme that Cd, Zn and Te raw materials which meet Cd1-xZnxTe (x is 0.04 to 0.8) and have the purity being 99.99999 percent are charged into a quartz crucible, a secondary sealing sleeve and a primary sealing sleeve are sequentially placed into the quartz crucible, the vacuum pumping is carried out until the pressure is 2.0*10<-4>Pa, and the quartz crucible is sealed and knotted at the primary sealing sleeve part. The sealed crucible is placed into a material blending furnace, the temperature is slowly raised to 500 DEG C, after the heat insulation for a certain time, the temperature is slowly raised, and the material blending and the heat insulation are carried out after the melting point of materials is reached. The temperature is slowly lowered to the room temperature, and the material blending is completed. Then, the crucible is taken out, the crucible is subjected to secondary pipe sealing at the secondary sealing sleeve part. The primary sealing sleeve part at the tail part is cut off, and the crucible containing CdZnTe materials is placed into a crystal growth furnace for carrying out single crystal growth. The size compression on the free space during the crystal growth is realized through using the double sealing sleeves by the secondary pipe sealing method, and in the subsequent single crystal growth process, the formation of Cd vacant sites in crystals can be effectively inhibited, so the performance of the crystals is improved.

Owner:SHANGHAI UNIV

Method for isolating stem cells and their use in cell therapy

The invention relates to a method for isolating muscle-derived stem cells that can be used in cell therapy, said method comprising the steps of (i) dissociating cells from at least one muscle sample, (ii) plating the cells obtained at the end of step (i) on a non-coated cell container, (iii) isolating the cells present in the supernatant of the non-coated cell container obtained at the end of step (ii), (iv) plating the cells obtained at the end of step (iii) on a coated cell container, (v) isolating the cells present in the supernatant of the coated cell container obtained at the end of step (iv), (vi) repeating, or not, the steps (iii) and (iv) at least one or two times, (vii) plating and culturing the cells isolated from the supernatant of the coated cell container obtained at the end of step (vi) until said cells have reached a confluence level of at least 50%, (viii) isolating, at the end of step (vii), the stem cells which can be used in cell therapy, wherein after expansion (a) at least 95% of said cells express CD44, CD73, (b) at least 95% of said cells express CD29, (c) at least 70% of said cells express CD90, and (d) said cells do not express CD4, CD8, CD34, CD45, CD31, CD1 17, CD144 and CD133. The invention also relates to said isolated stem cells and pharmaceutical compositions containing them.

Owner:INSTITUT NATIONAL DE LA RECHERCHE AGRONOMIQUE +1

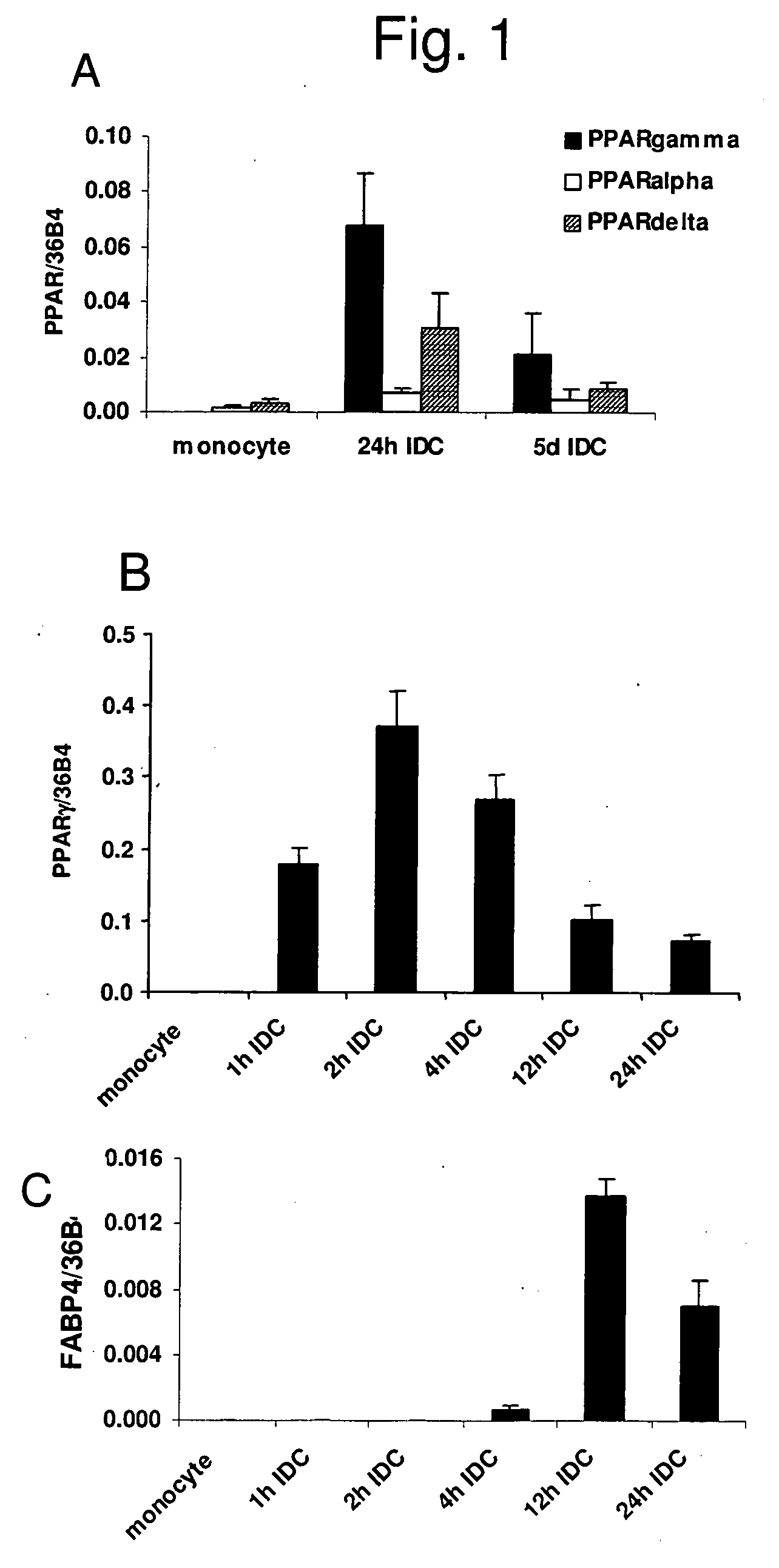

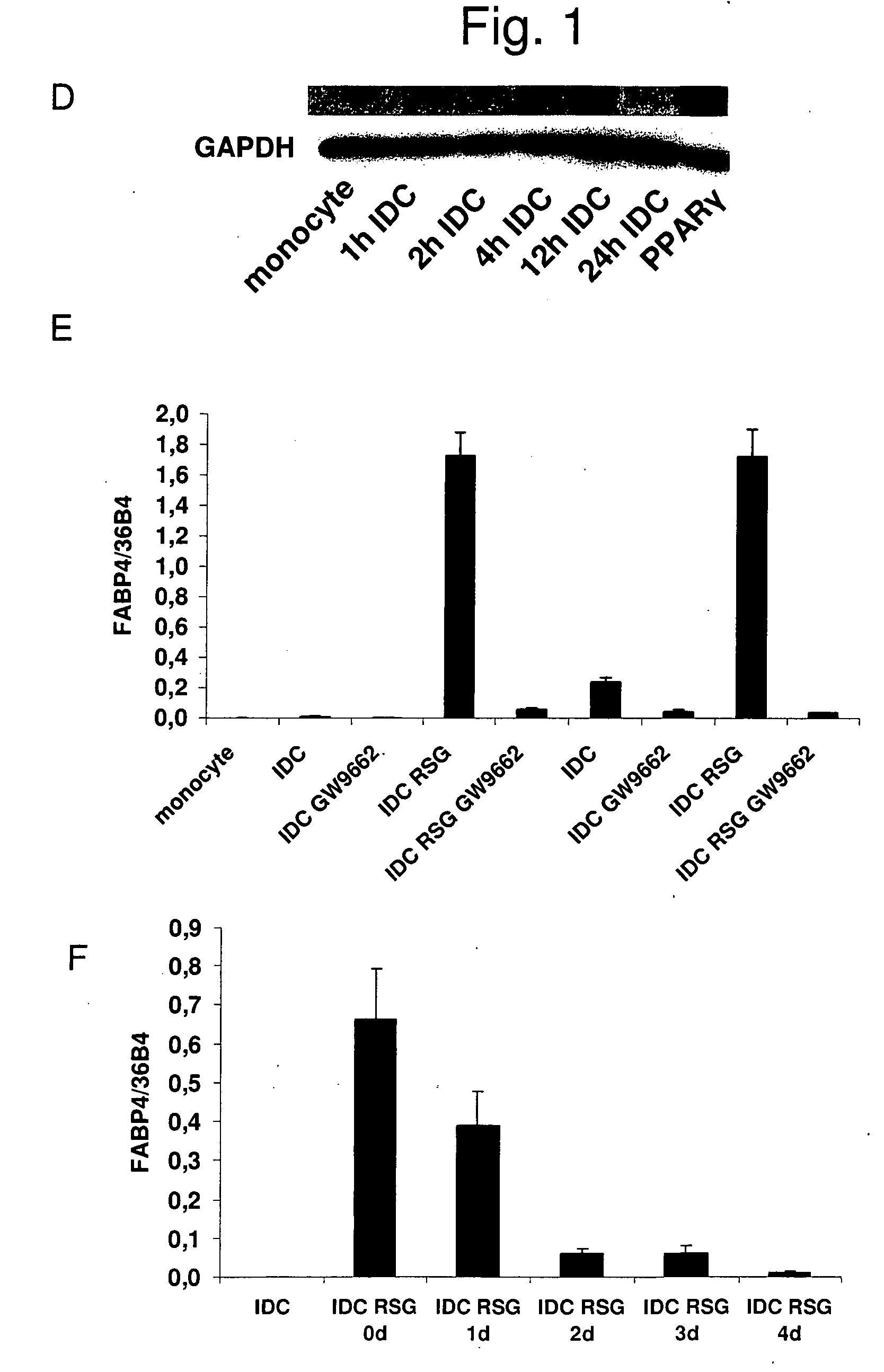

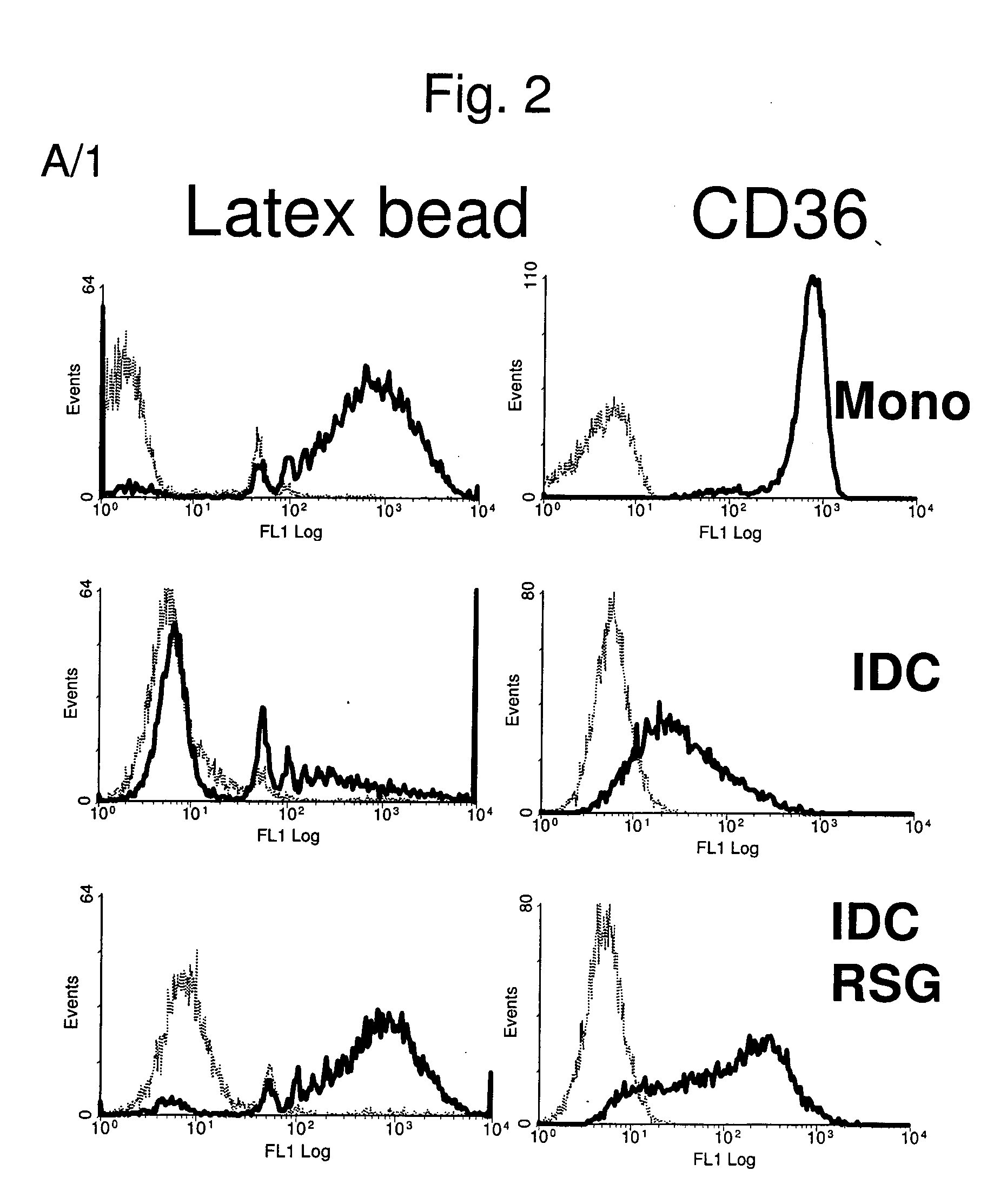

Novel uses of PPAR modulators and professional APCs manipulated by the same

InactiveUS20060159669A1Ameliorate any conditionAltered phenotypeBiocideGenetic material ingredientsAntigenAutoimmune condition

The invention relates to a manipulated professional antigen presenting cell (APC) having increased expression of a CD1 type II molecule, preferably at least a CD1d molecule, relative to a control non manipulated cell. The invention further relates to the use of PPARg modulators in the preparation of a pharmaceutical composition or kit for the treatment of a disease treatable by activation of CD1d restricted T-cells, e.g. in autoimmune diseases, allergies, post-transplant conditions or infectious diseases, or in the treatment of a neoplastic disease, e.g. skin cancer, hematological tumors, colorectal carcinoma, and therapeutic compositions and kits therefor. Furthermore, the invention relates to methods of manipulating professional APCs and kits therefor.

Owner:UNIVERSITY OF DEBRECEN

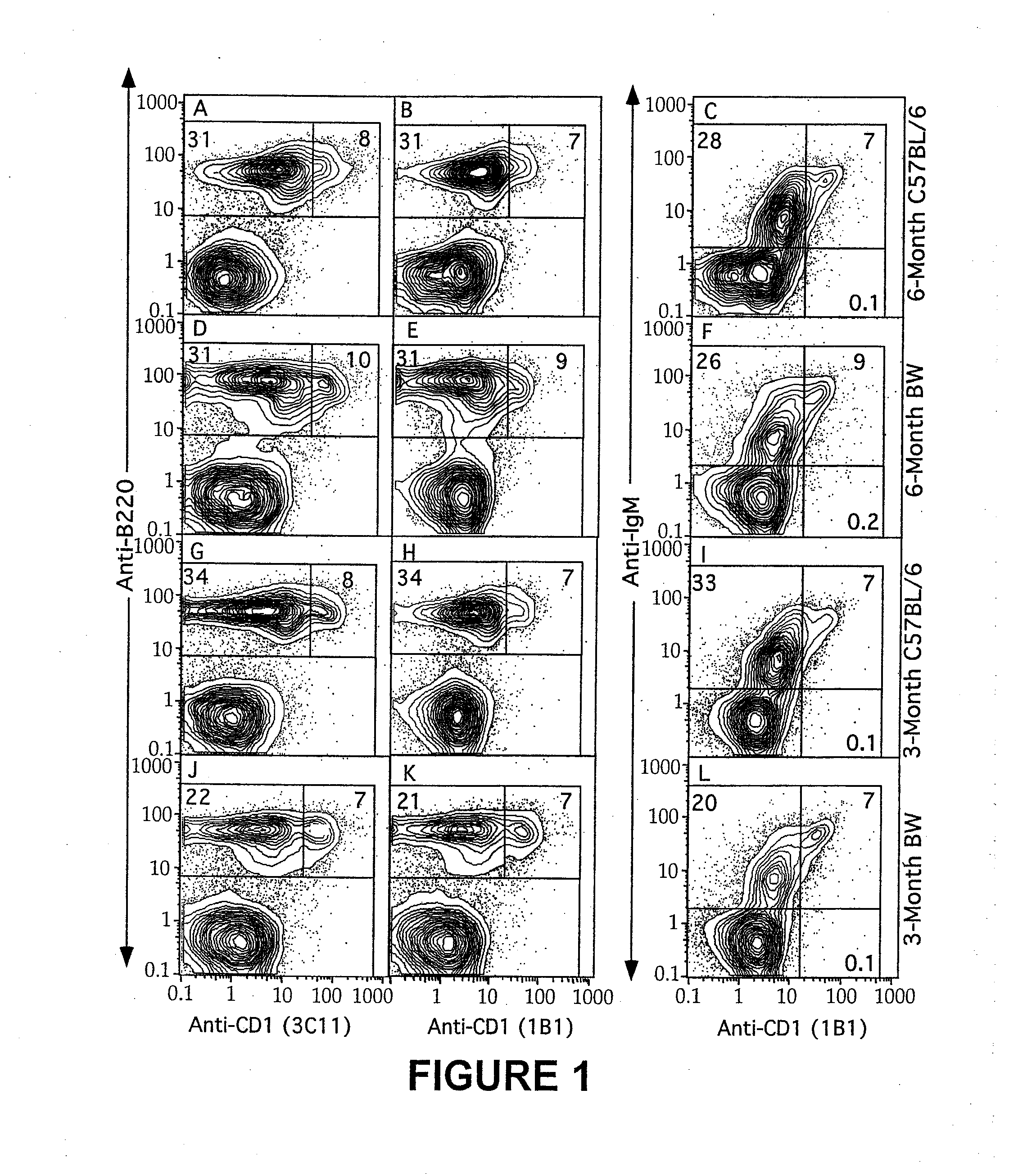

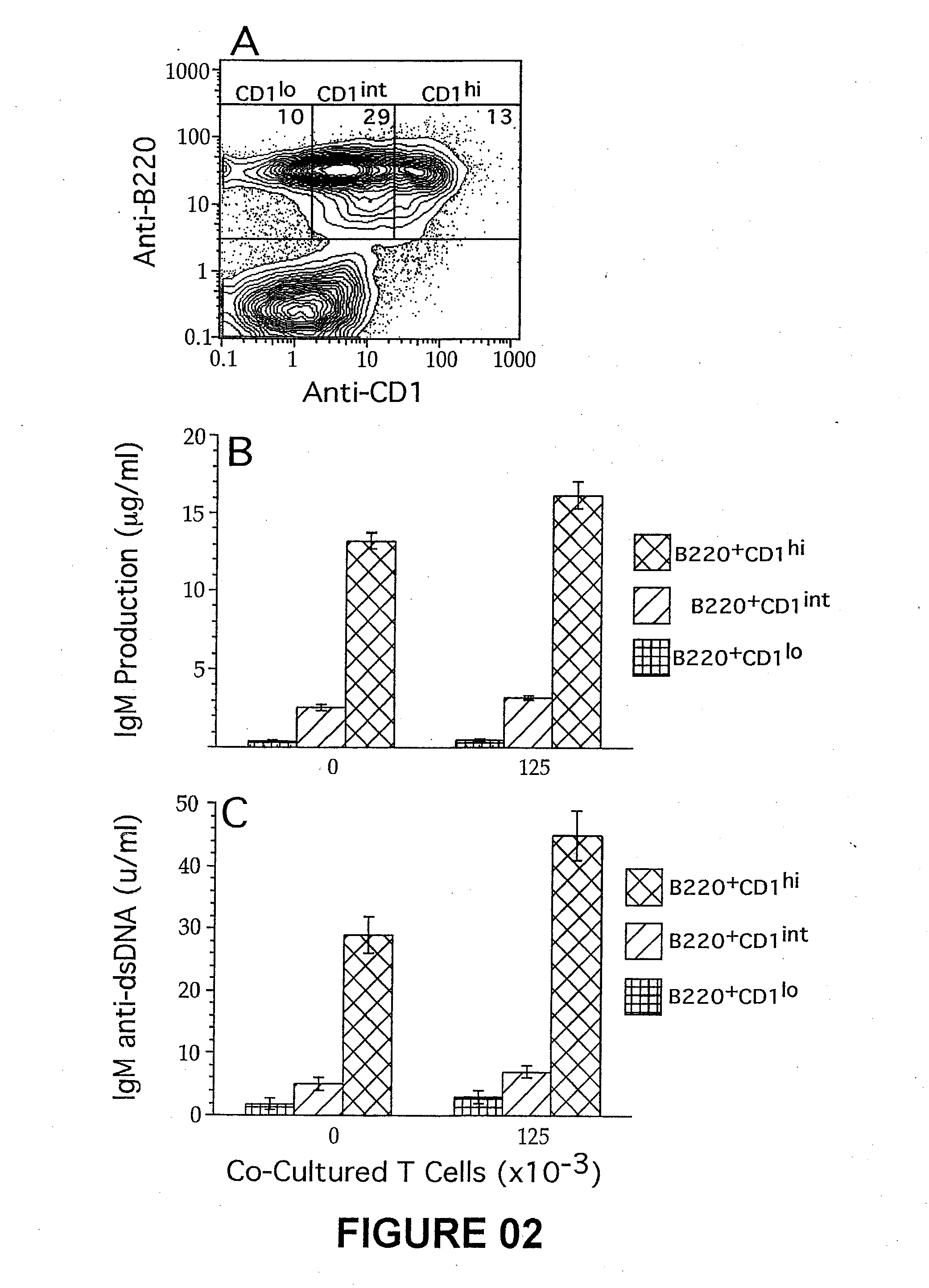

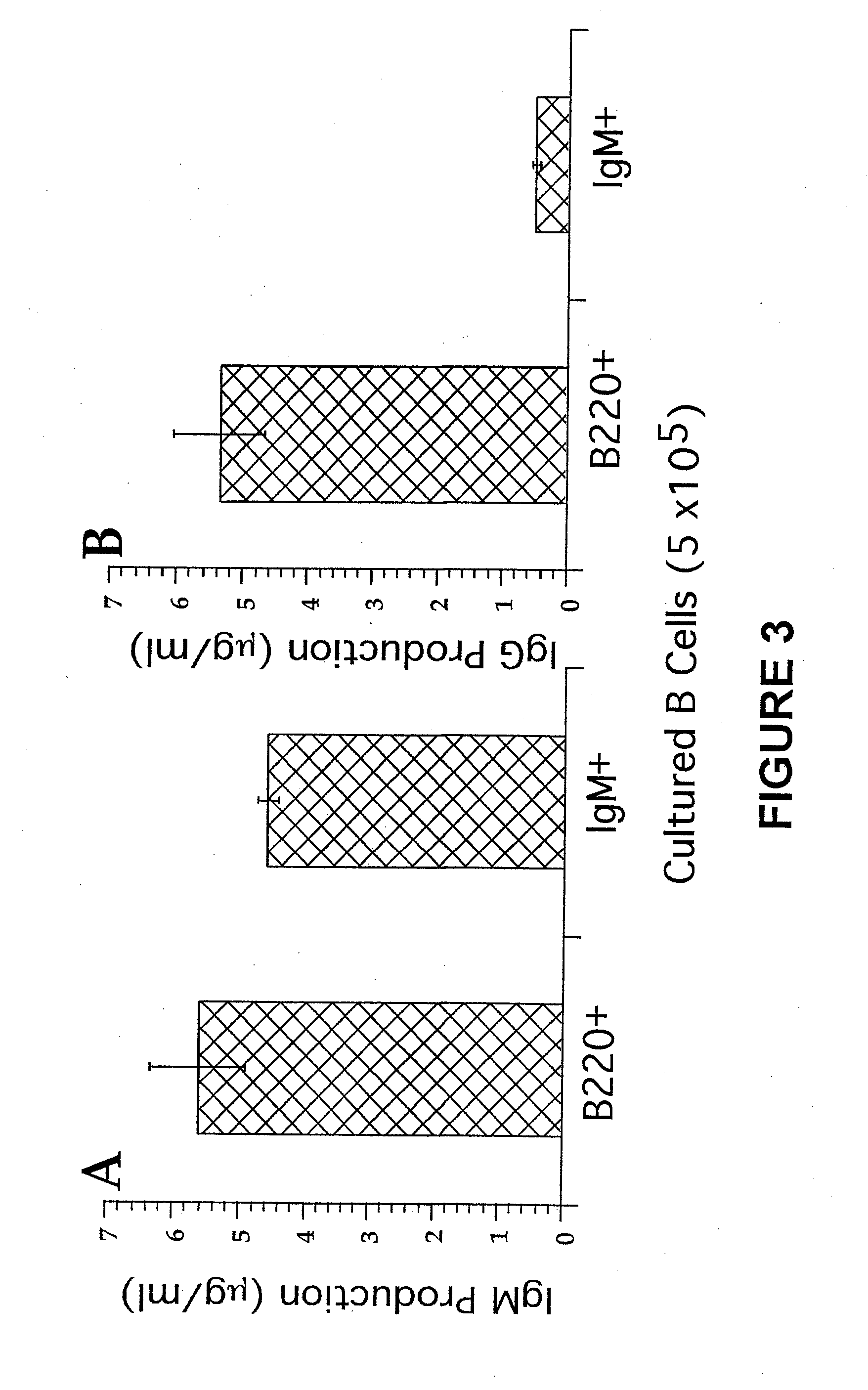

Methods for inhibition of polyclonal b cell activation and immunoglobulin class switching to pathogenic autoantibodies by blocking cd1-mediated interactions

InactiveUS20110038860A1Slow onsetReduces level of serum IgGBiocidePeptide/protein ingredientsAntigen receptorT-Cell Antigen Receptors

Pathogenic polyclonal B cell activation and immunoglobulin class switching to pathogenic autoantibodies is inhibited by binding molecules that specifically interfere with CD1 antigen, but do not activate signaling (blocking agents), or by molecules that bind to the T cell antigen receptor on T cells that recognize CD1. When CD1 mediated signaling is thus blocked, the T cell response is diminished, resulting in reduced polyclonal B cell activation and reduced immunoglobulin class switching to pathogenic autoantibodies.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

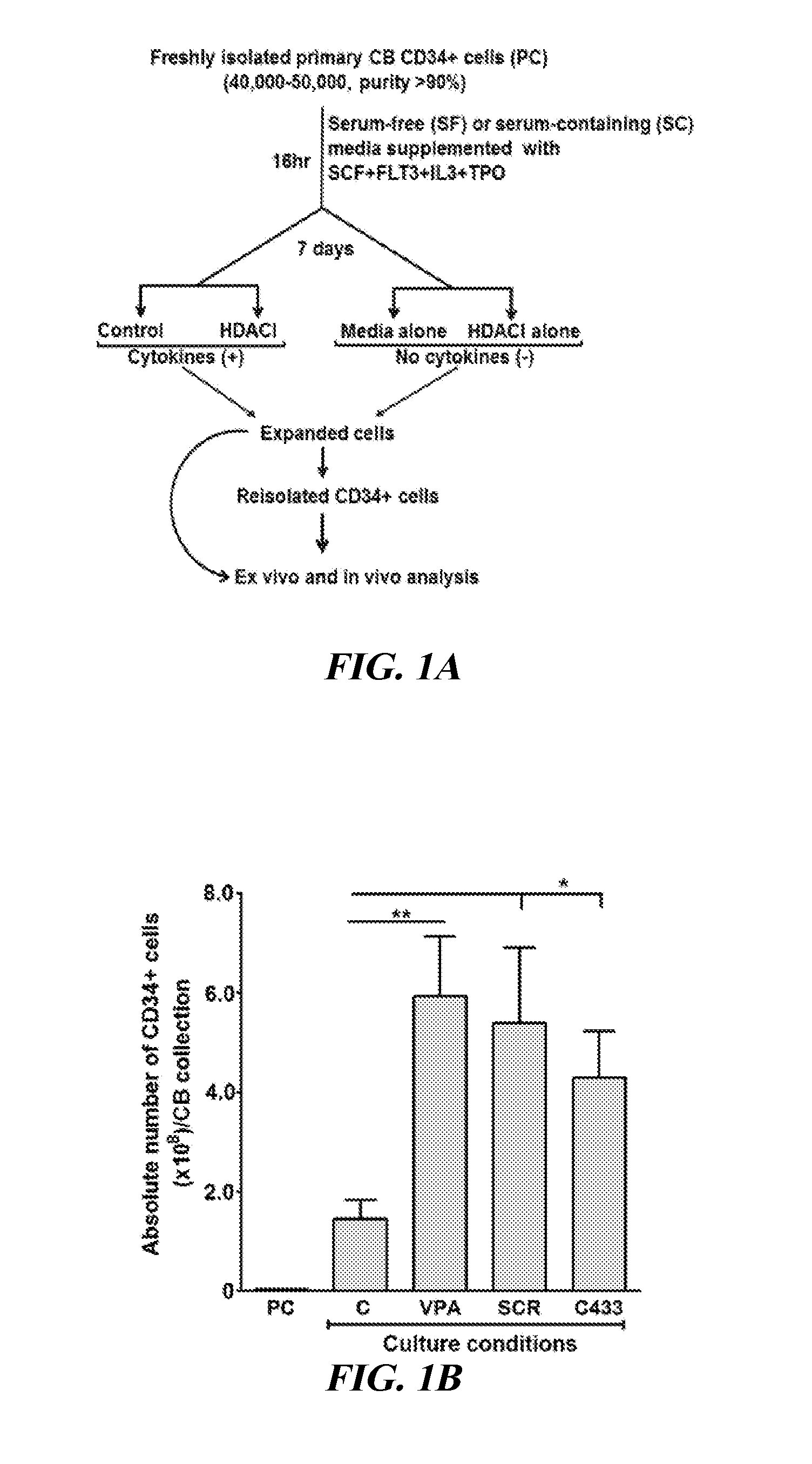

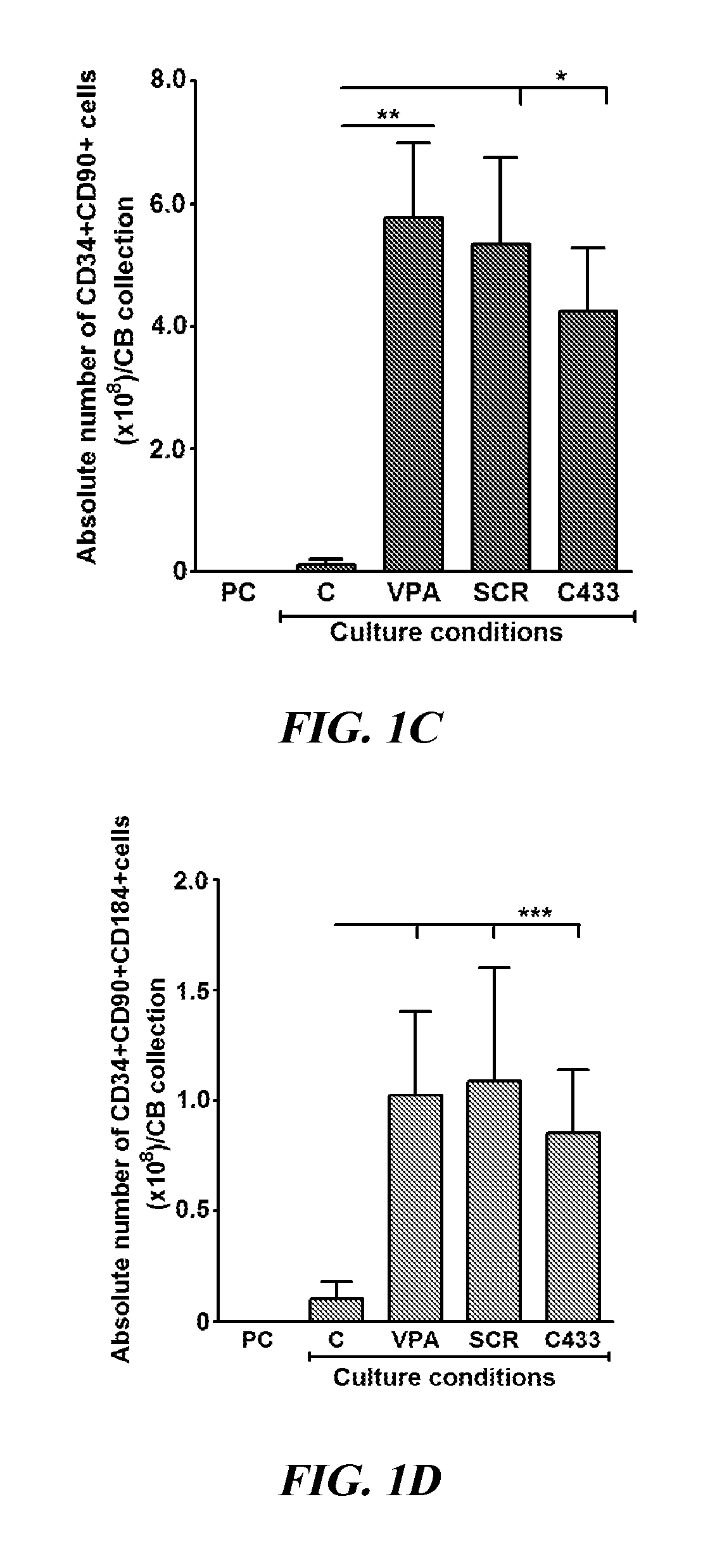

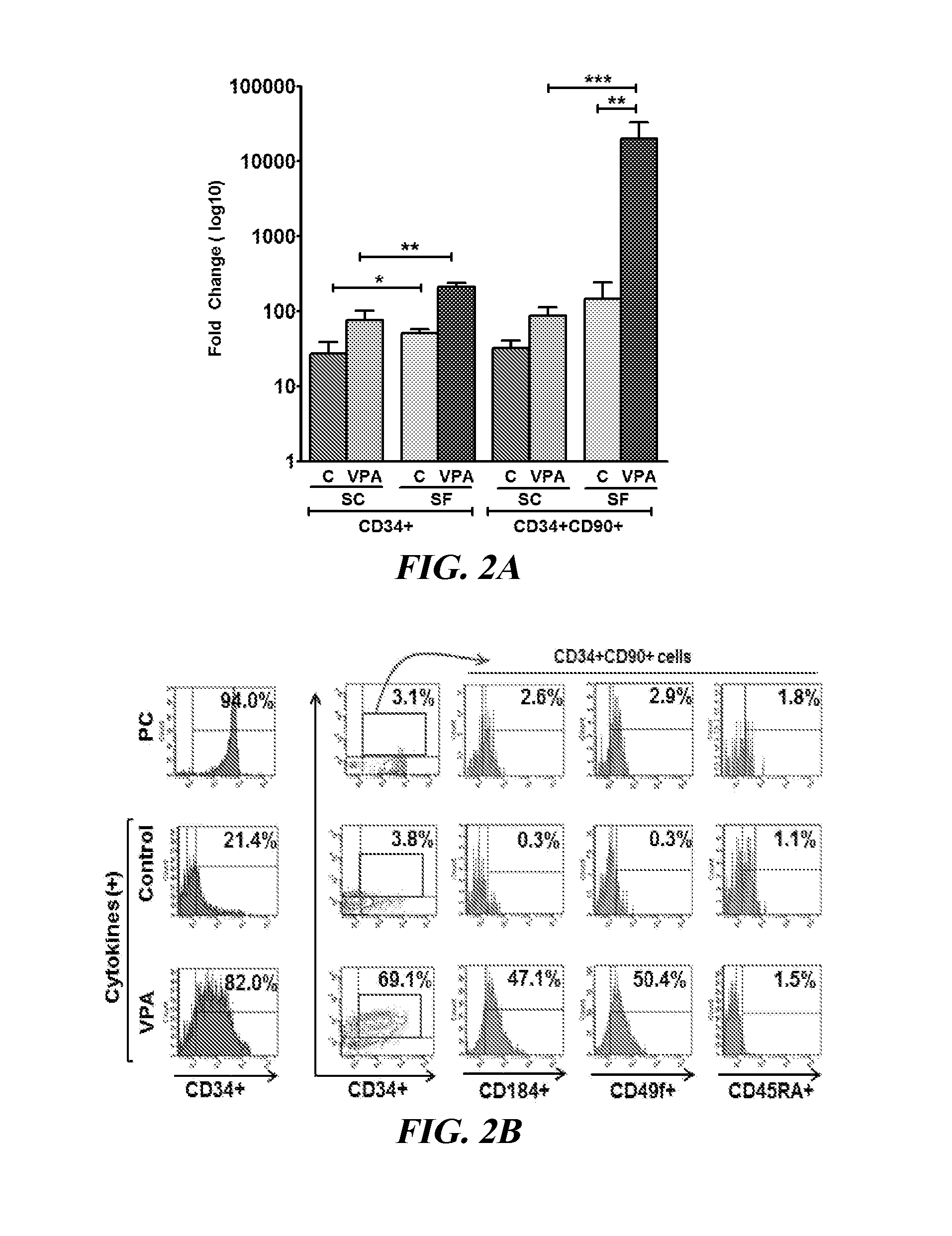

Enriched and expanded human cord blood stem cells for treatment of hematological disorders

ActiveUS20160097036A1High activityHigh expressionMicrobiological testing/measurementCulture processCord blood stem cellSOX2

This invention relates to an enriched population of isolated and expanded human cord blood stem cells and a method of producing an enriched population of isolated and expanded human cord blood stem cells. The expanded human cord blood stem cells are CD34+, CD90+, CD1 84+, CD1 17+, CD49f+, ALDH+, CD45RA− and express pluripotency genes SOX2, OCT4, NANOG, and ZIC3. In one embodiment, the stem cells in the enriched population of the present invention are positive for aldehyde dehydrogenase activity (ALDH+). In addition, in one embodiment the expanded stem cells are nearly depleted of T cells and B cells and contain a limited number of monocytes (CD14). Also disclosed is a method of treating a subject for a hematological disorder using the stem cells of the present invention and a method of determining the effects of a compound on hematopoietic stem cells.

Owner:MT SINAI SCHOOL OF MEDICINE

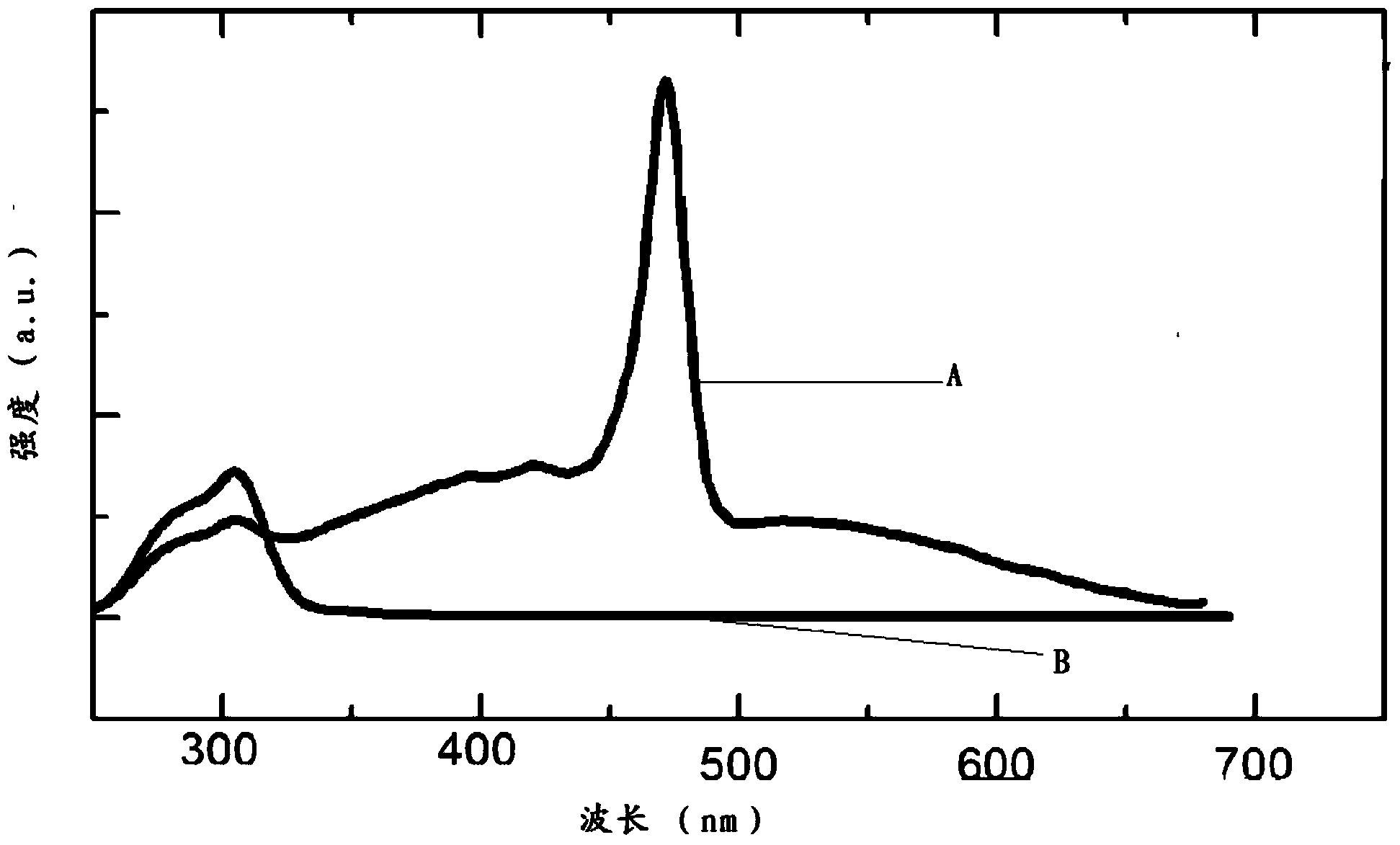

Luminescent material with core-shell structure and preparation method thereof

ActiveCN103642495AGood light conversion effectImprove luminous efficiencyLuminescent compositionsHigh absorptionSemiconductor materials

The invention provides a luminescent material with a core-shell structure. A rare earth luminescent material is taken as a core, and a semiconductor Cd1-xZnxS is taken as a shell; the rare earth luminescent material takes rare earth ions as a luminescent center; and the range of Zn component in the Cd1-xZnxS is as follows: x is not less than 0 and less than 1. The semiconductor material has strong absorption against photons which are higher than a band gap, a quasi-continuous energy band structure allows a semiconductor to have a very high absorption coefficient in a very wide spectral range, and electrons excited by the high-energy photons can effectively relax to the bottom of a conduction band for downward transition luminescence. Therefore, the prepared luminescent material with the core-shell structure has the advantages of excellent light conversion performance and high luminescence efficiency. The luminescent material provided by the invention adopts a full-solid reaction method combining hot pressure sintering and high-temperature annealing, any solvent is not added in the whole process, the introduction of compound inclusions containing C-H and C-O bonds is avoided, and the relatively high luminescence efficiency is further ensured.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

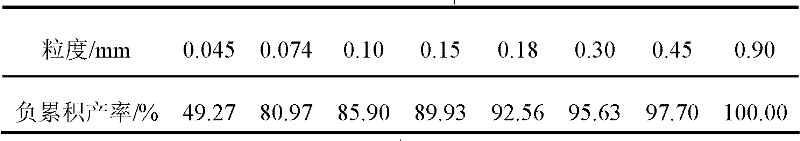

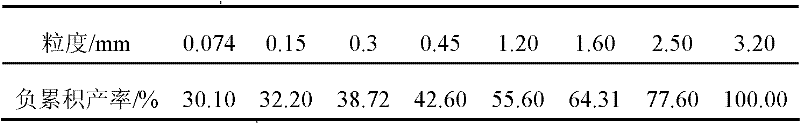

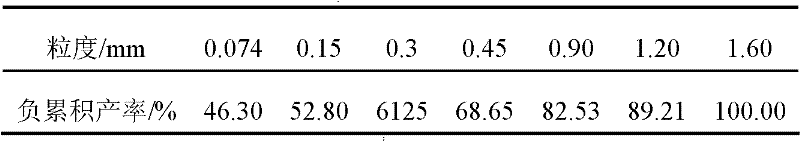

Gradation design method of tailing autoclaved bricks

InactiveCN102390944AReduce development costsReduce labor intensitySolid waste managementBrickMathematical model

The invention concretely relates to a gradation design method of tailing autoclaved bricks. The technical scheme is as follows: mathematical models of the particle size di of an aggregate of the tailing autoclaved bricks and the pass percentage Pdi of the particle size the established, i.e., Pdi=62.25 (di / dmax) 0.22+37.75 (di / dmax)K. The gradation design method comprises the following steps of: firstly, selecting the maximum particle size (dmax=1-7mm) of the aggregate by combining the characteristic of a tailing particle size, then determining a gradation modified index K, and then obtaining the pass percentage Pdi of different particle sizes di according to the mathematical models; and finally, obtaining tailing mixing content Ct=Pdi / Sd1*100wt%, d1-d2 size fraction adjusted aggregate mixing content Cd1-d2=Pd1-d2-(Sd2-Sd1)*(Pd1 / Sd1),......, d(n-1)-dn size fraction adjusted aggregate mixing content Cd(n-1)-dn=Pd(n1-1)-dn-(Sdn-Dd(n-1))*(Pd1 / Sd1) according to a minus cumulative yield Sd1of the particle size di in the characteristic of the tailing particle size. The gradation design method can be used for remarkably reducing the researching and manufacturing costs and the labor intensity and effectively promoting the utilization of tailings in the field of autoclaved bricks, and has the characteristics of high tailing utilization ratio and good strength.

Owner:WUHAN UNIV OF TECH

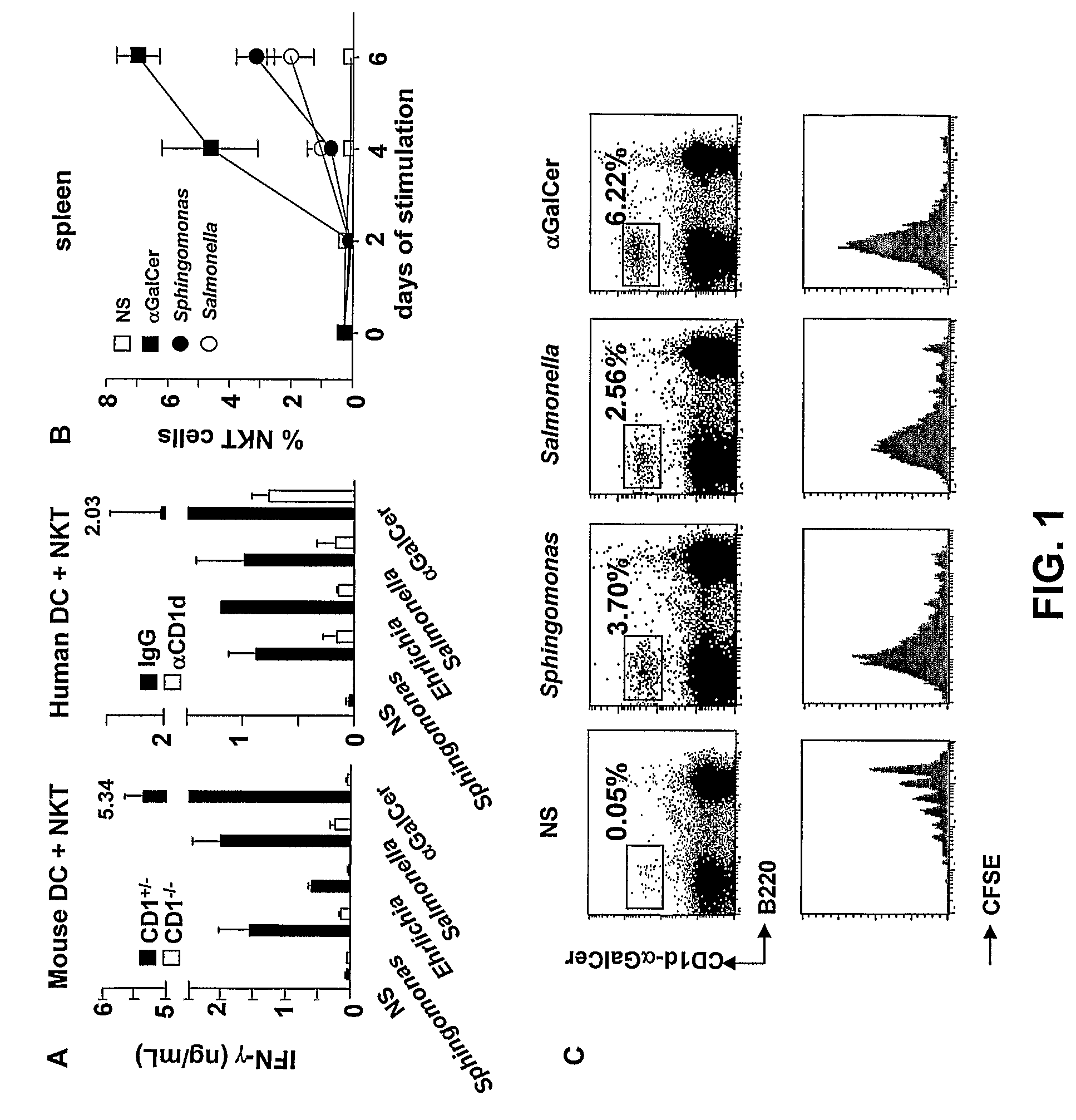

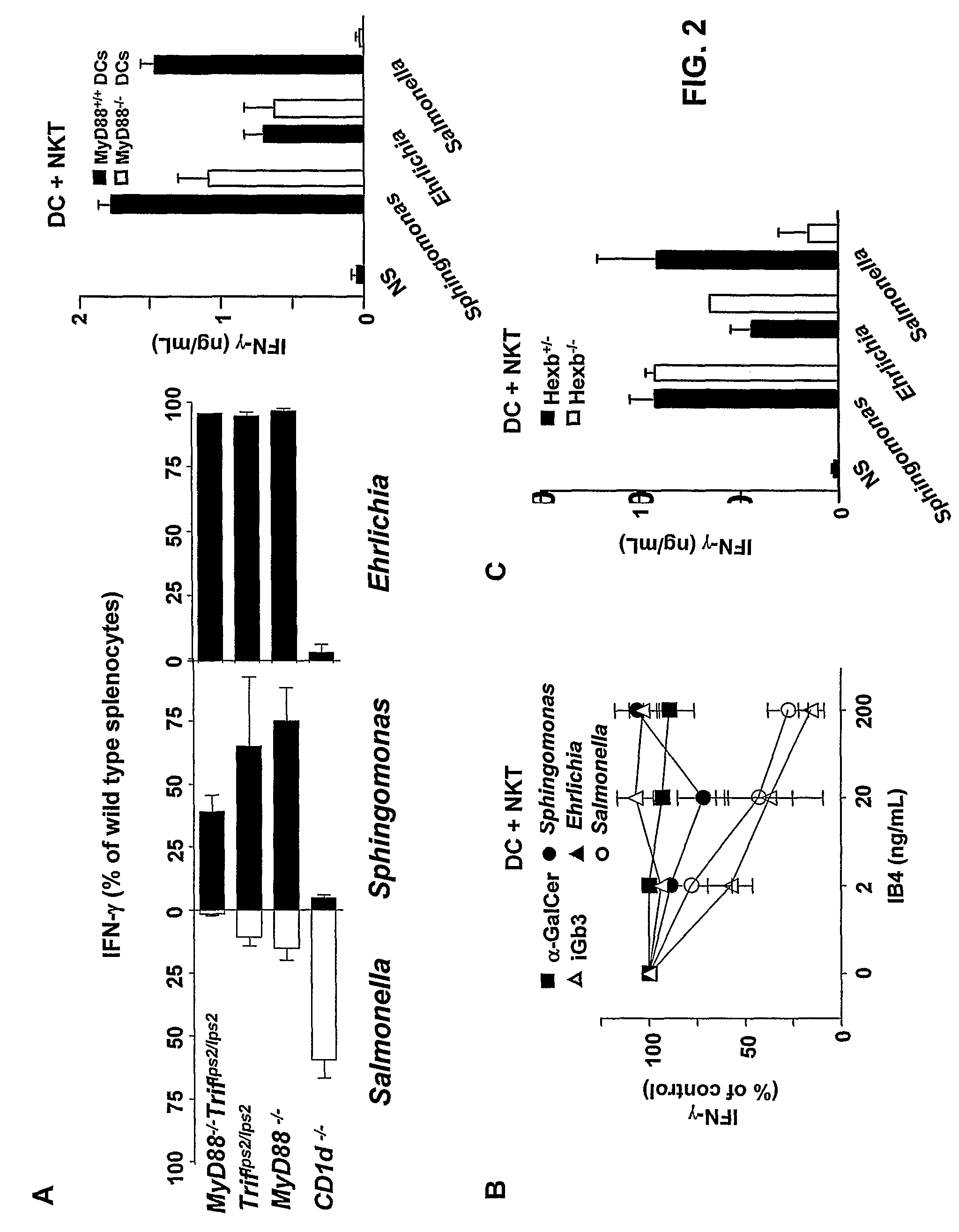

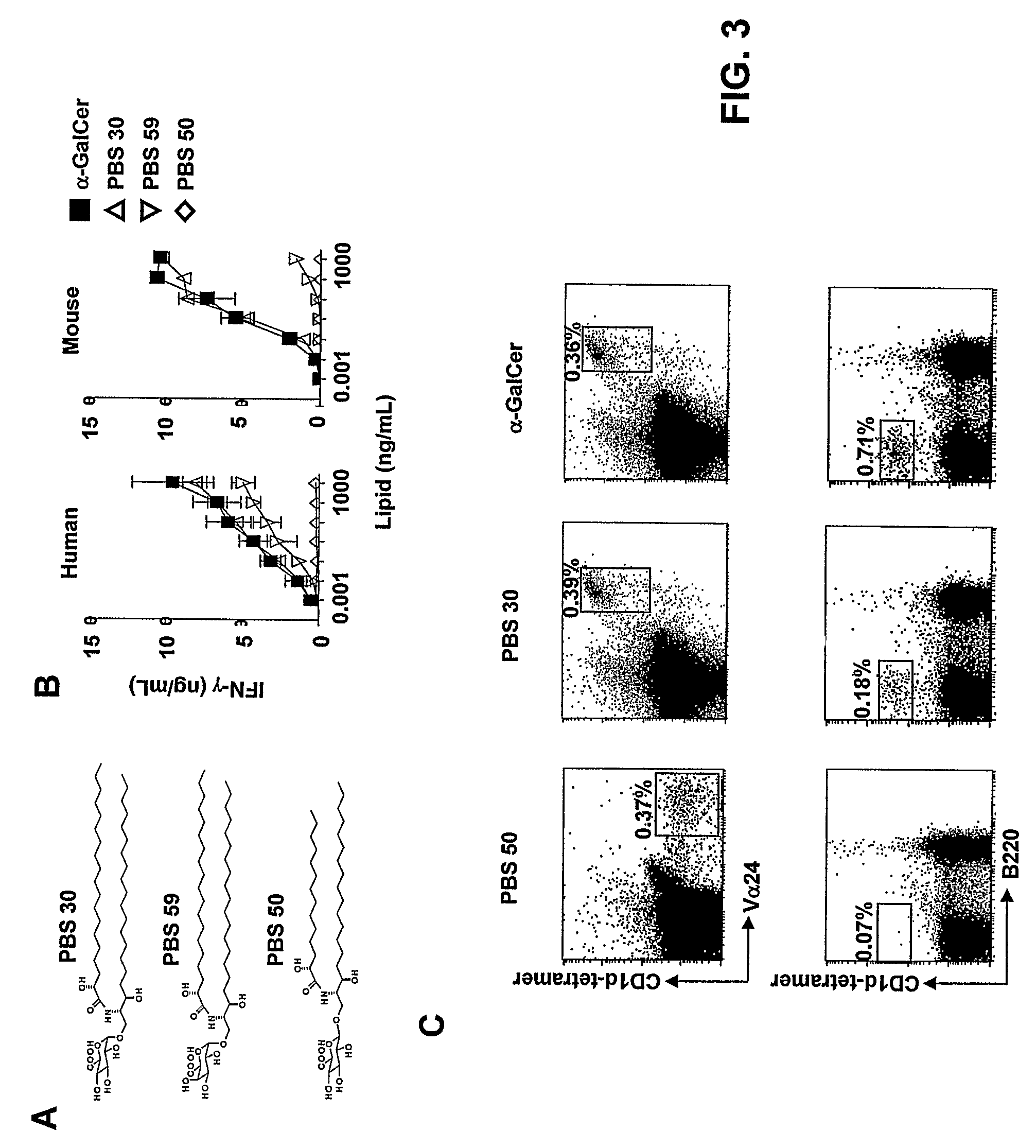

Bacterial glycolipid activation of CD1d-restricted NKT cells

Owner:THE SCRIPPS RES INST +2

Use of anti-CD1 antibodies for the modulation of immune responses

InactiveUS8084020B2Downregulation of IL-12 productionInhibiting and stabilizing progressionAntibacterial agentsNervous disorderAutoimmune responsesAllergy

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

Improved methods and compounds for eliminating immune responses to therapeutic agents

ActiveCN108289941APeptide/protein ingredientsAntibody mimetics/scaffoldsTherapeutic proteinChemical compound

The invention describes a kit of parts of polypeptides. The kit comprises: a) a peptide comprising : a1) an MHC class II T cell epitope or a CD1 d-restricted NKT cell epitope, and a2) a [CST]-X(2)-C [SEQ ID NO:7] or C-X(2)-[CST] [SEQ ID NO:8] oxidoreductase motif sequence immediately adjacent to said epitope or separated by at most 7 amino acids from said epitope, and b) a polypeptide comprising:b1) a therapeutic protein and b2) the epitope defined in a1), wherein the epitope sequence is a sequence which differs from the sequence of the protein of b1). The therapeutic protein, in combinationwith the peptide, is used to prevent an immune response against the therapeutic protein.

Owner:IMCYSE

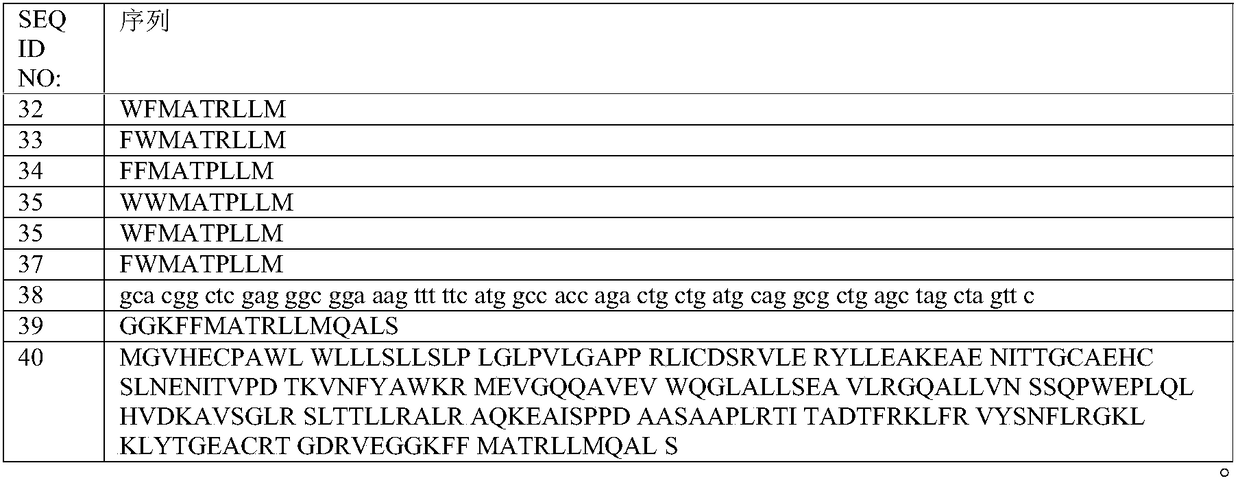

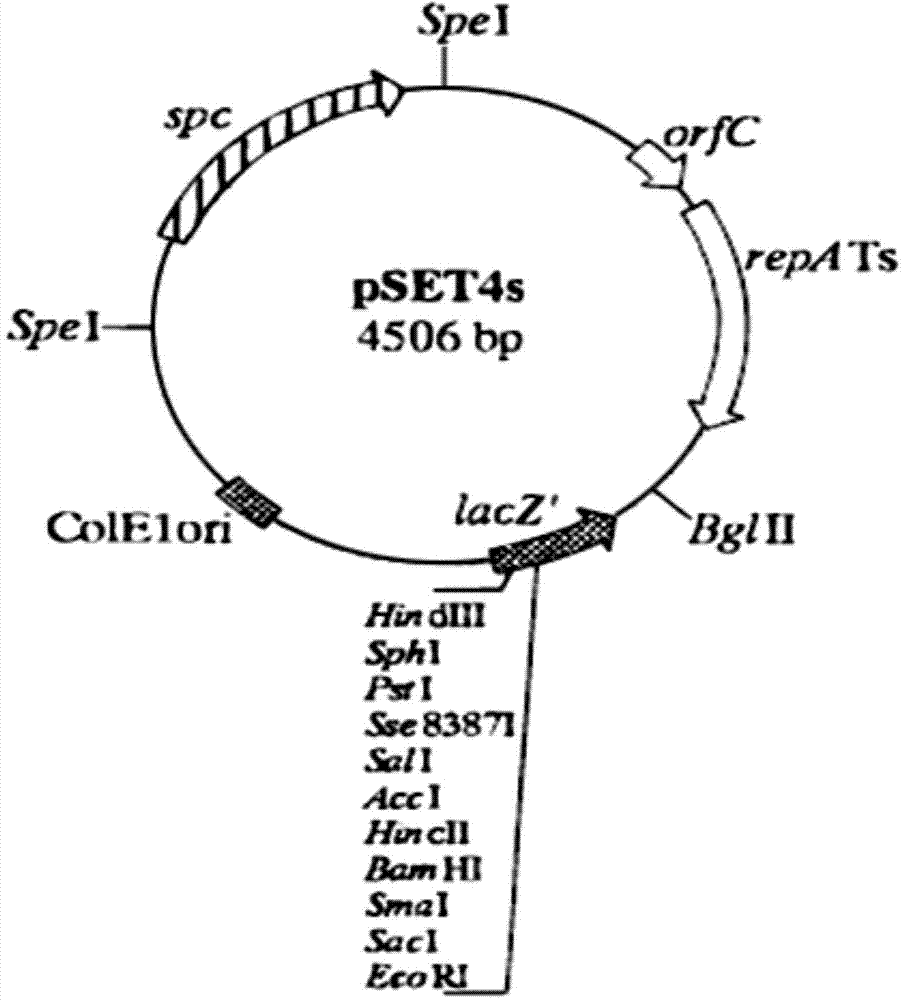

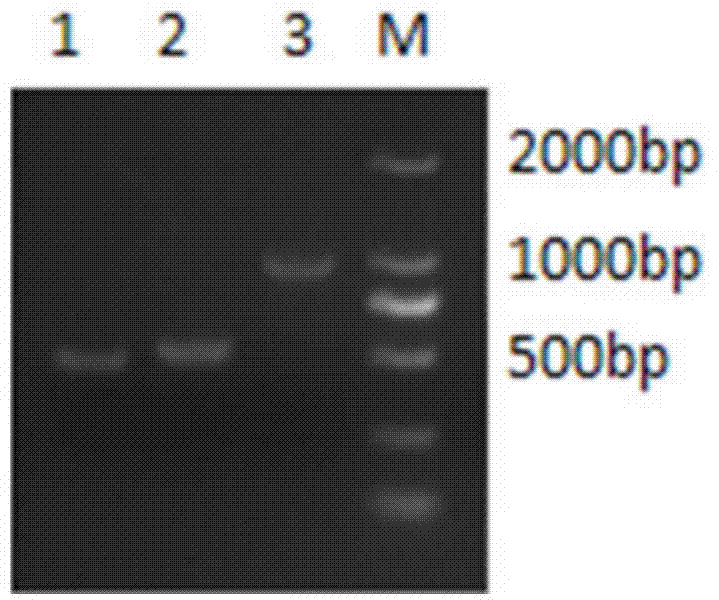

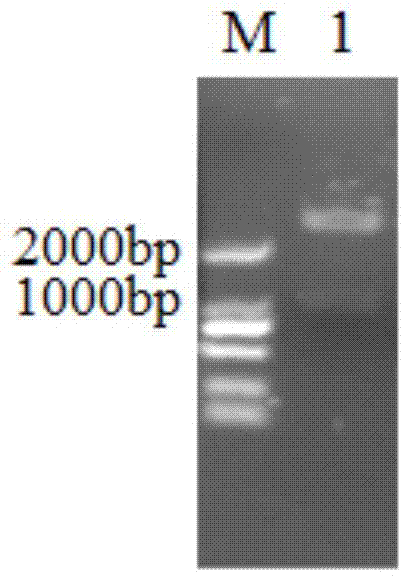

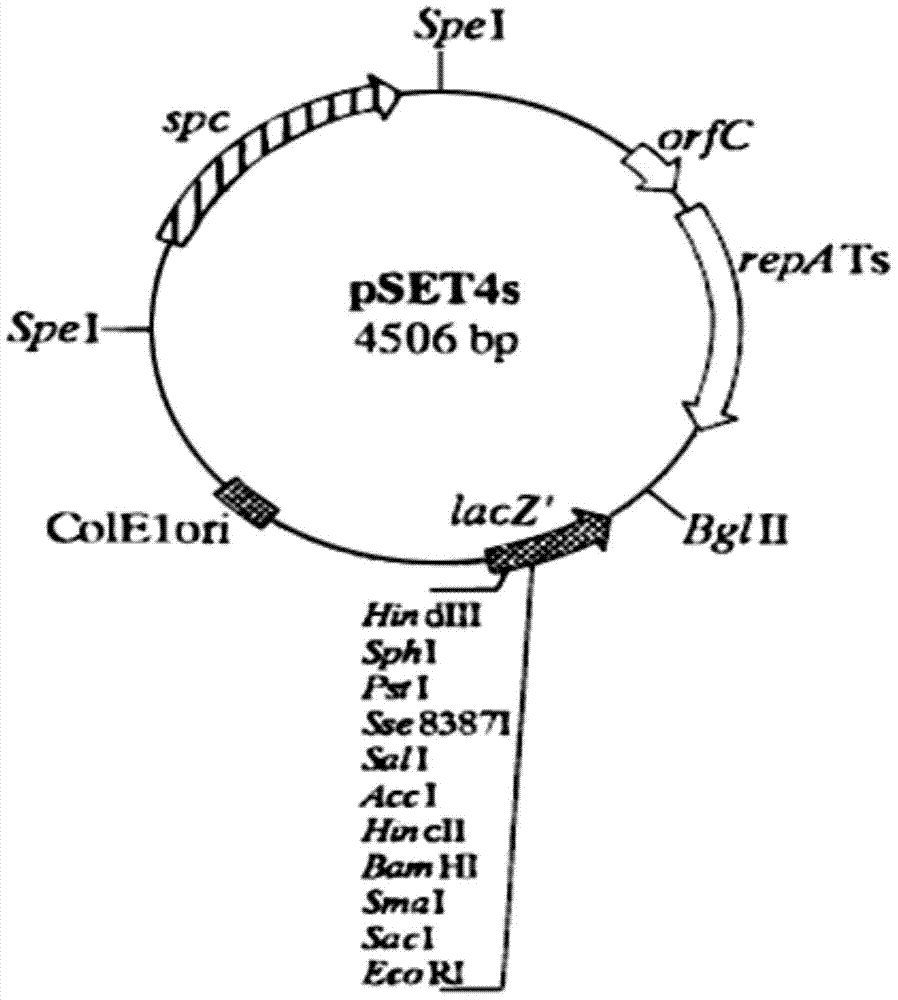

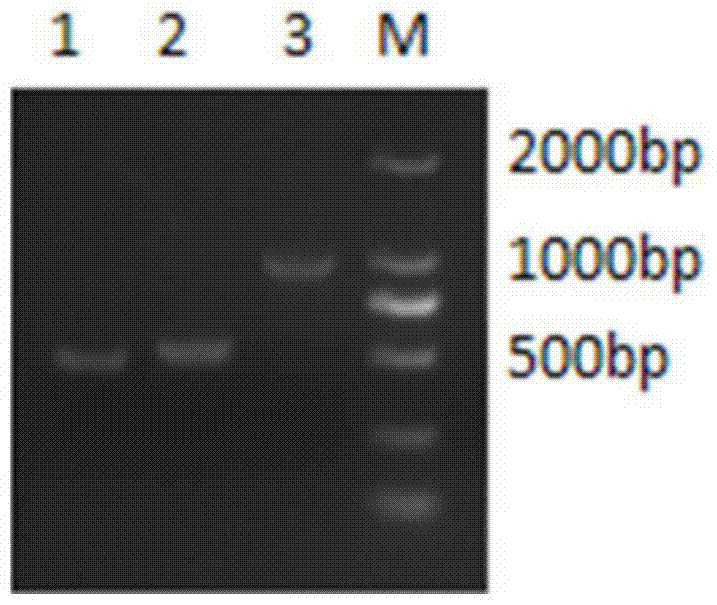

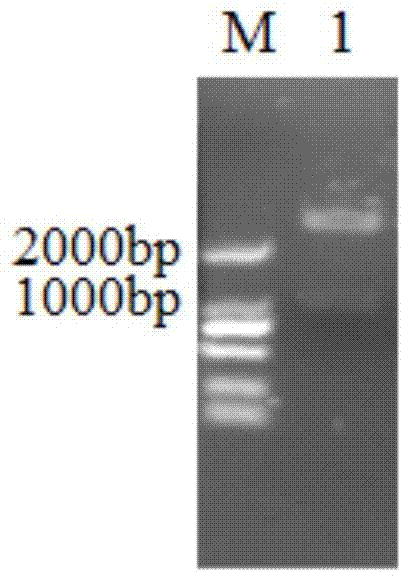

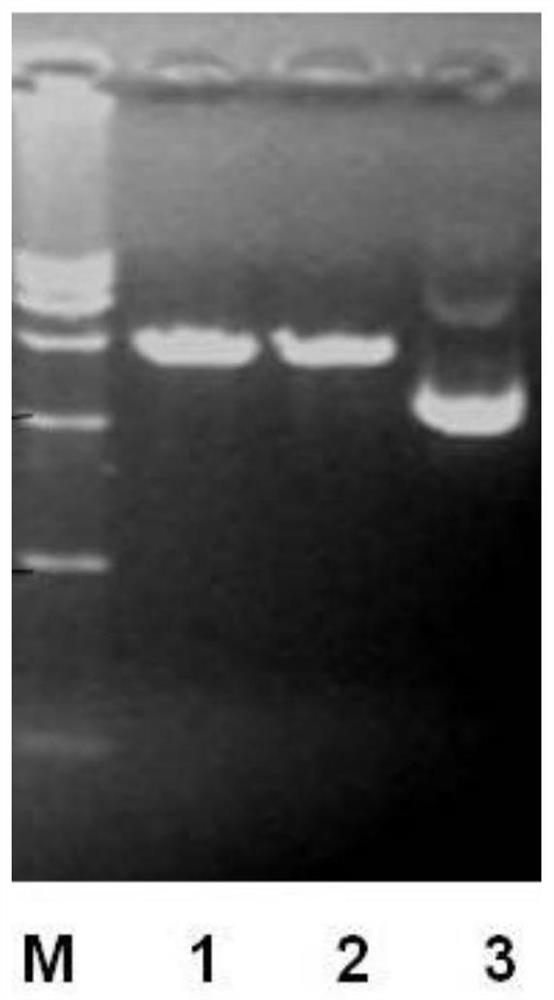

Streptococcus suis SBP-bac-5 gene deletion strain and construction method and application thereof

ActiveCN104762244ATargetedWeak toxicityAntibacterial agentsBacterial antigen ingredientsBacteroidesEukaryotic plasmids

The invention discloses a streptococcus suis SBP-bac-5 gene deletion strain and a construction method and application thereof, the streptococcus suis SBP-bac-5 gene deletion strain is SS delta SBP-bac-5 containing no resistance maker, and the preservation number is CGMCC No.10076. Rec A homologous recombination system is used, temperature-sensitive suicide plasmid pSET4s as a carrier is used for deletion of a gene coded by the streptococcus suis type 7 strain SBP-bac-5 to obtain the streptococcus suis SBP-bac-5 gene deletion strain, and SBP-bac-5 protein expression can be destroyed. Compared with a parent strain, the streptococcus suis type 7 SS delta SBP-bac-5 strain is weaker in toxicity and safe to animals. A vaccine is prepared by use of recombinant bacteria for immunization of CD1 mice, the experimental results show that: the streptococcus suis recombinant bacteria vaccine can effectively induce production of specific humoral immune response, so that the immunized mice can be protected against S.suis (streptococcus suis) attacks, and bacteria multiplication in the body can be effectively prevented. The engineering bacteria provides an important basis for the development of vaccine of streptococcus suis vaccines.

Owner:HARBIN VETERINARY RES INST CHINESE ACADEMY OF AGRI SCI

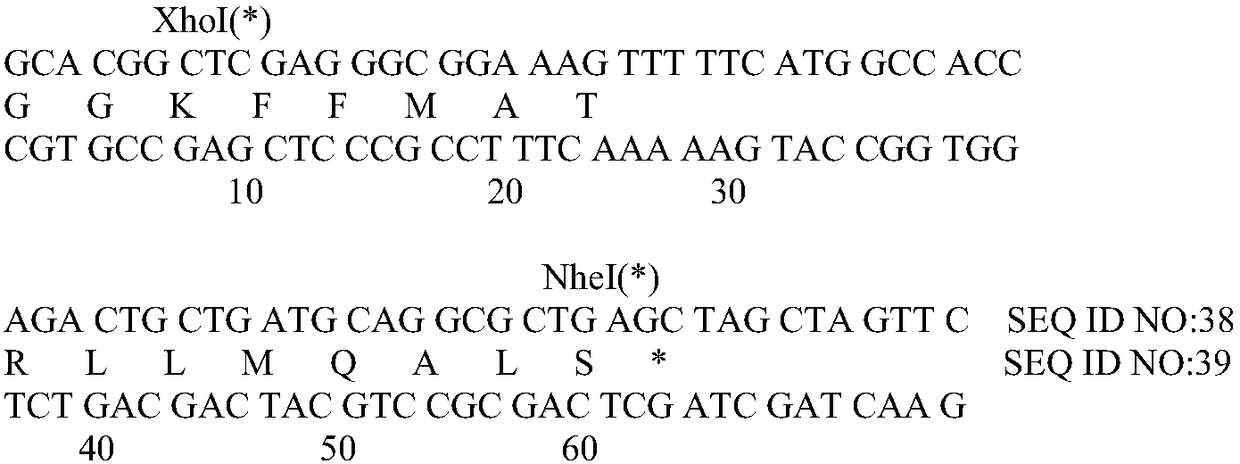

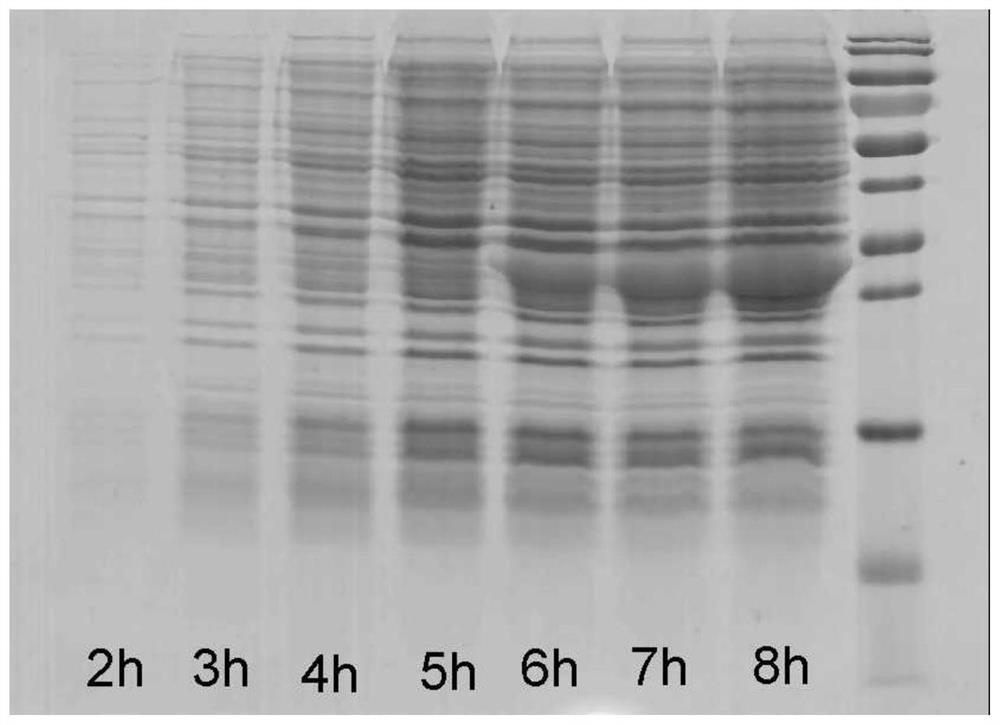

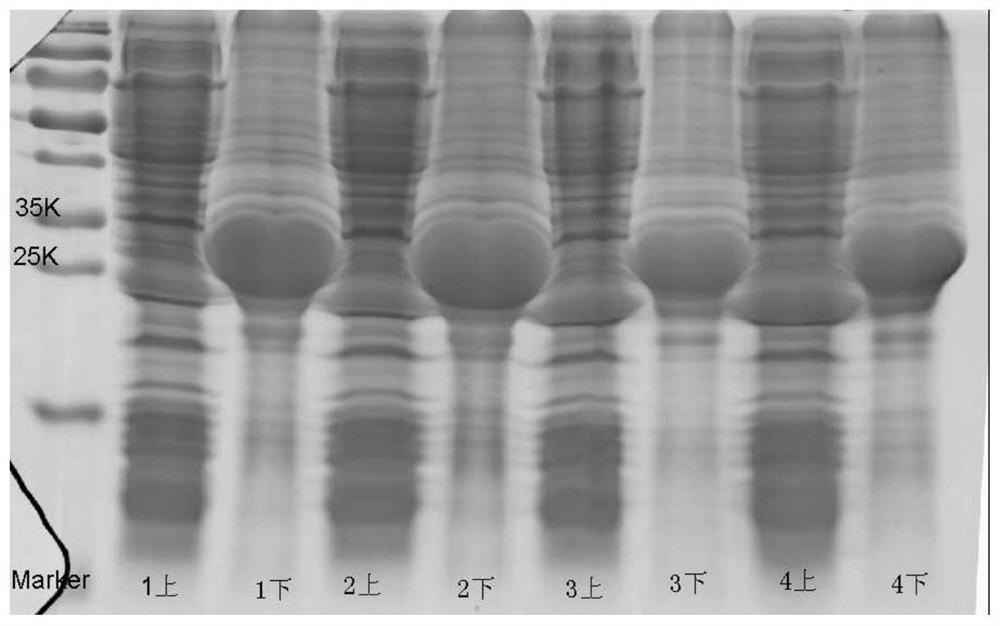

Radioactive anti-peptide mutant protein and preparation and purification method thereof

ActiveCN108484738AImprove stabilityEasy to storeBacteriaMicroorganism based processesMutated proteinPurification methods

The invention discloses a radioactive anti-peptide mutant protein and a preparation and purification method thereof. By adopting the method, the purity of a protein can be remarkably improved, and convenience can be brought to industrial production. The invention further provides a radioactive anti-peptide mutant protein. The mutant protein is generated by replacing amino acid sequences between ND1 and CD1 on the basis of a radioactive anti-peptide protein CBLB502, and the mutant protein has an amino acid sequence of SEQ ID NO:2 as shown in the specification, and the stability of the mutant protein is remarkably prior to that of the CBLB5-2 protein in the prior art.

Owner:ACADEMY OF MILITARY MEDICAL SCI +2

A kind of human t-lymphoblastic leukemia/lymphoma cell line and its application

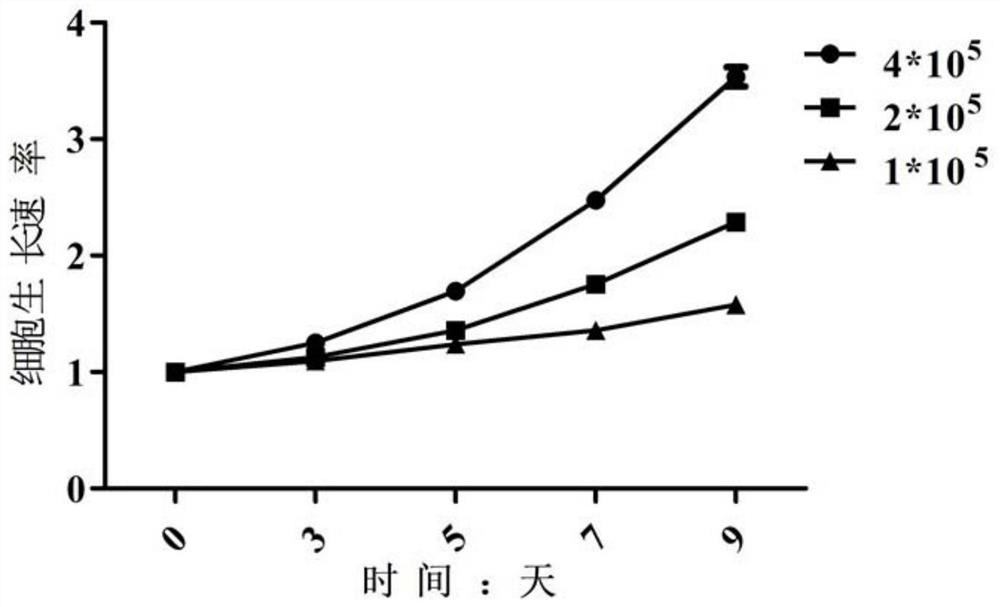

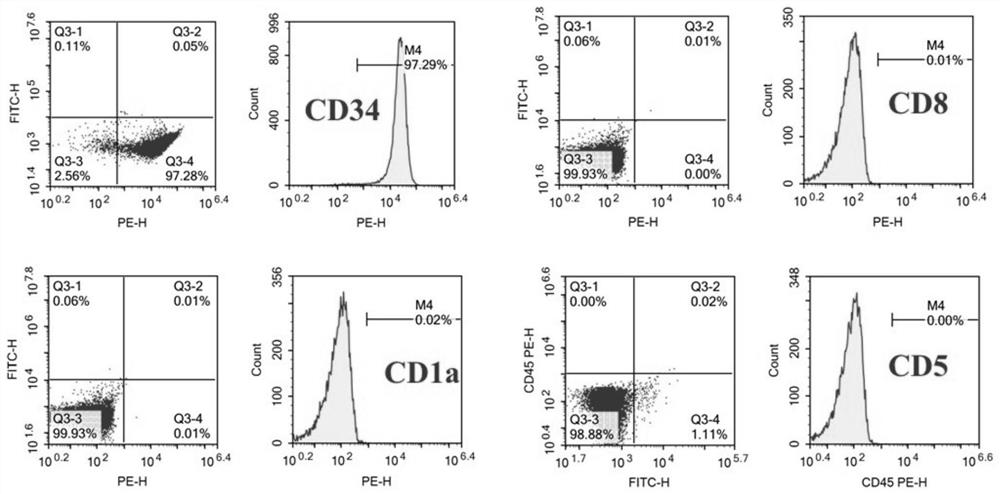

ActiveCN112877290BIn vitro shape stabilityIn line with clinical tumor biological characteristicsMicrobiological testing/measurementDrug screeningCD5CD8

The invention discloses a human T-lymphoblastic leukemia / lymphoma cell line and its construction method and application. The human T-lymphoblastic leukemia / lymphoma cell line is named as human T-lymphoblastic leukemia / lymphoma ZYXY-T1, and was deposited in the China Center for Type Culture Collection (Wuhan University, Wuhan, China) on January 20, 2021, with a deposit number It is CCTCC NO:C202143. The present invention is obtained by extracting and separating mononuclear cells from the peripheral blood of clinical human T-lymphoblastic leukemia / lymphoma patients, and culturing them in vitro for continuous natural passage. This leukemia cell line has the typical surface antigen expression characteristics of ETP‑ALL, that is, it does not express CD1α, CD5, CD8, highly expresses the stemness marker CD34, has good in vitro proliferation ability and in vivo tumorigenesis ability, and can be used as a study on the development mechanism of ETP‑ALL Research and individualized treatment In vitro research cell materials can also be used for in vivo and in vitro research ETP‑ALL drug screening, evaluation, and guidance for clinical medication.

Owner:ZHEJIANG UNIV

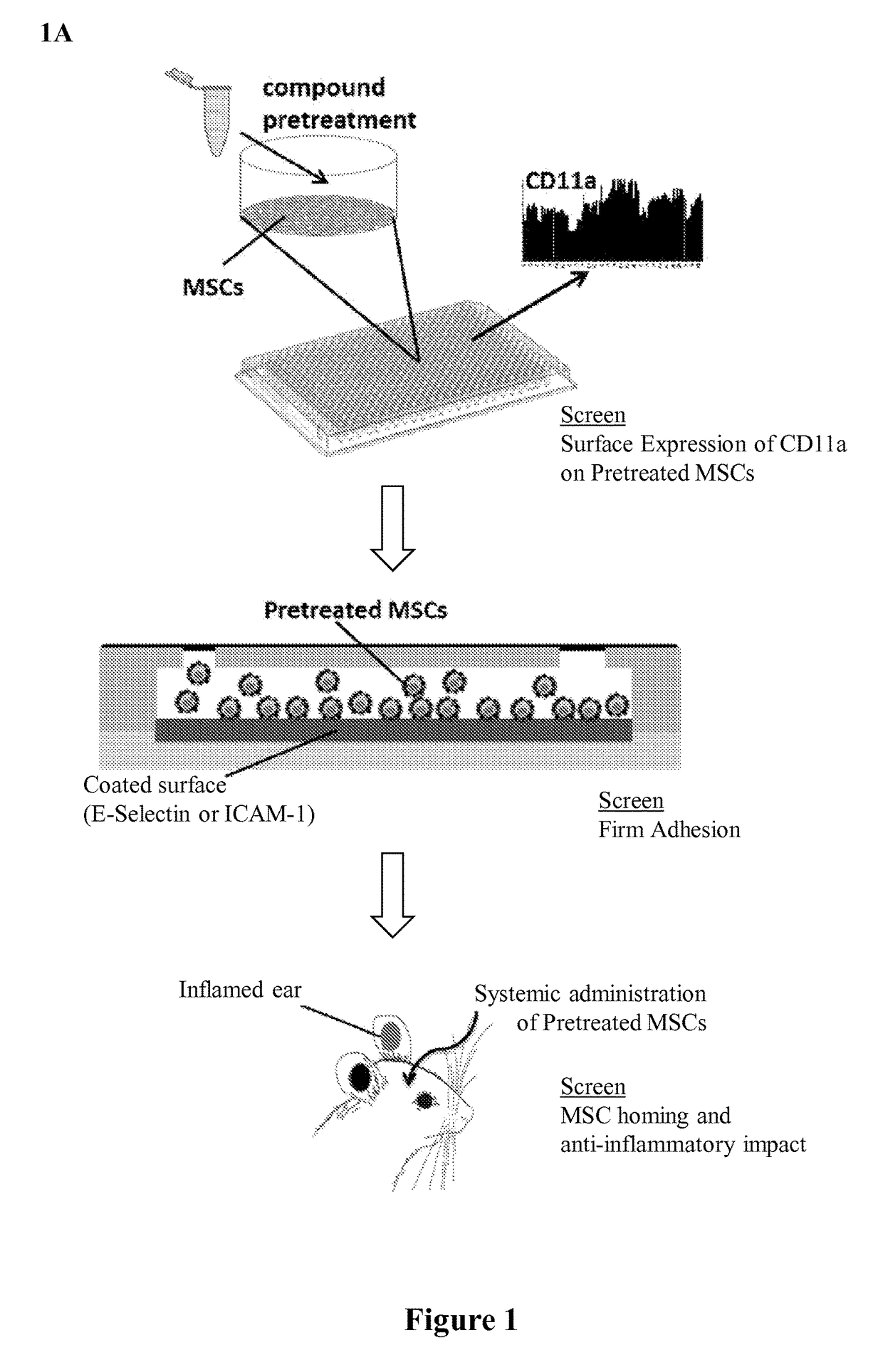

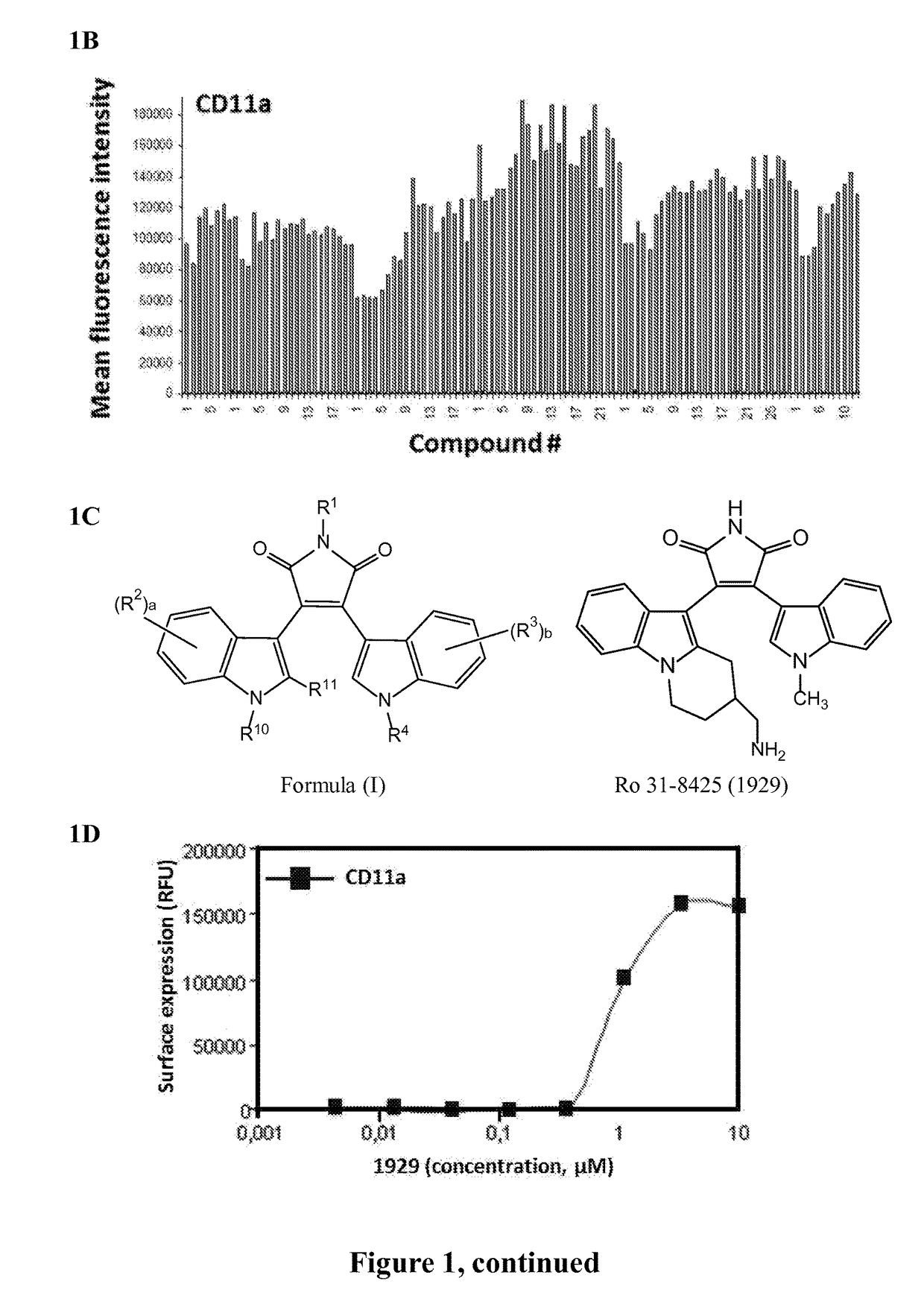

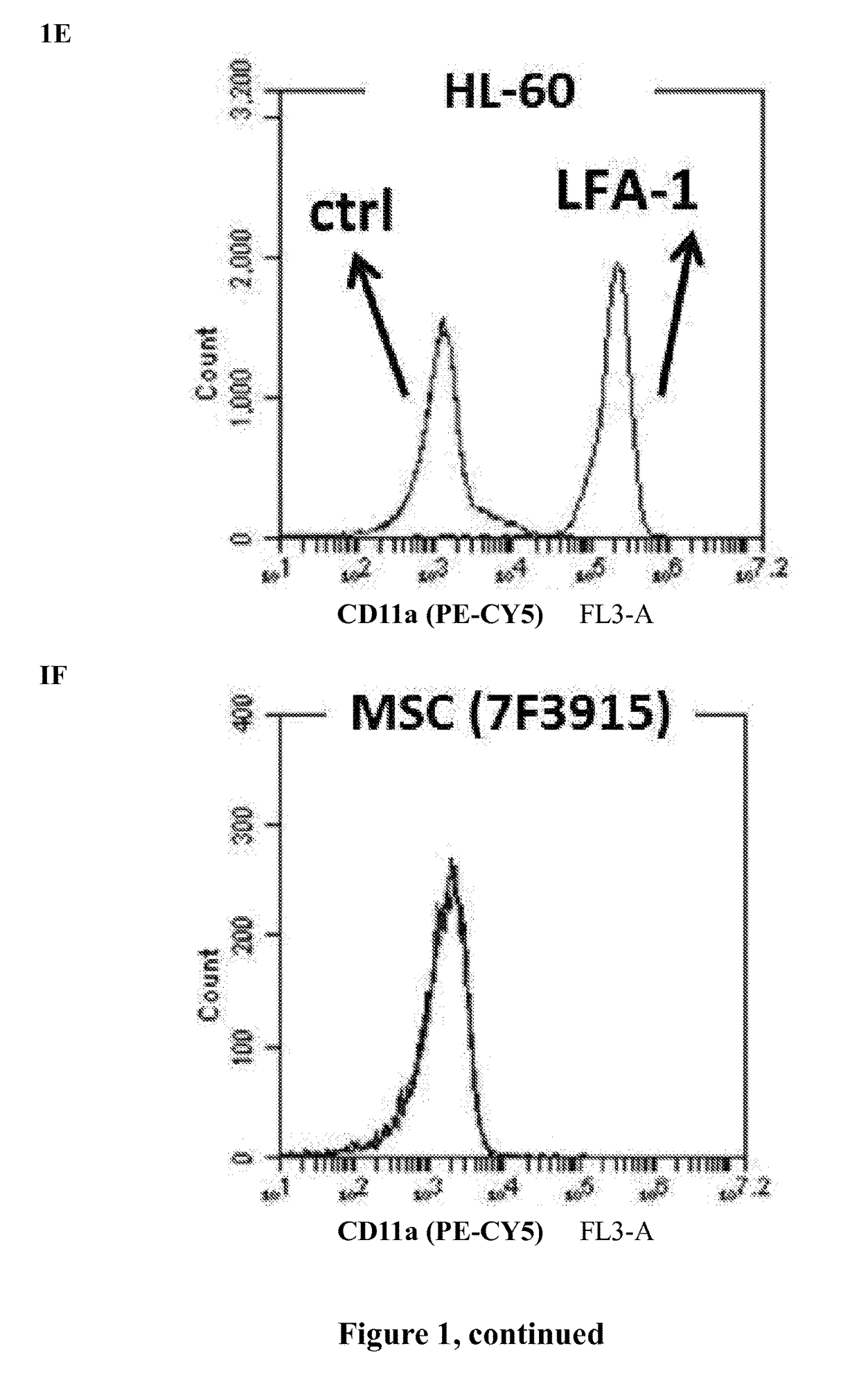

Methods and compositions for improving homing of cells including mesenchymal stem cells

InactiveUS20170216360A1Function increaseEnhanced cell surface expressionBiocideOrganic active ingredientsWhole bodyScreening method

The disclosure relates to methods and compositions for improving homing of cells including mesenchymal stem cells (MSCs). Compositions include compounds described herein as capable of inducing expression by MSCs of cell surface homing ligand molecules such as CD1 la, promoting increased firm adhesion by MSCs in an in vitro shear flow assay, increasing binding to an adhesion molecule such as E-selectin or ICAM-1, and / or demonstrating anti-inflammatory activity upon in vivo systemic administration in cell therapy using human MSCs. Also described are screening methods to identify small molecule compounds for improving a homing function of MSCs.

Owner:THE GENERAL HOSPITAL CORP +2

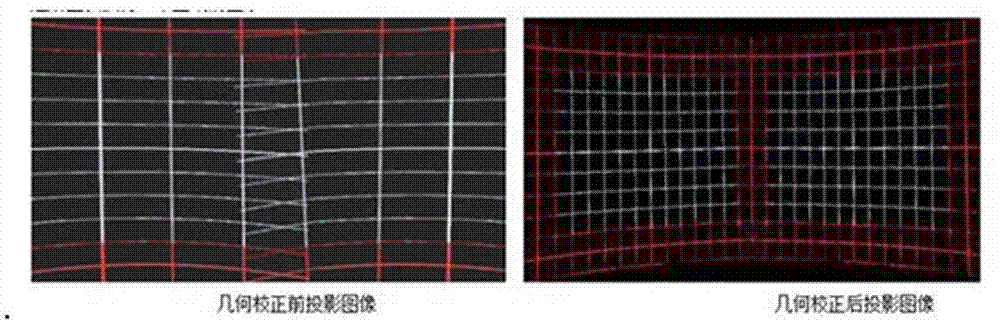

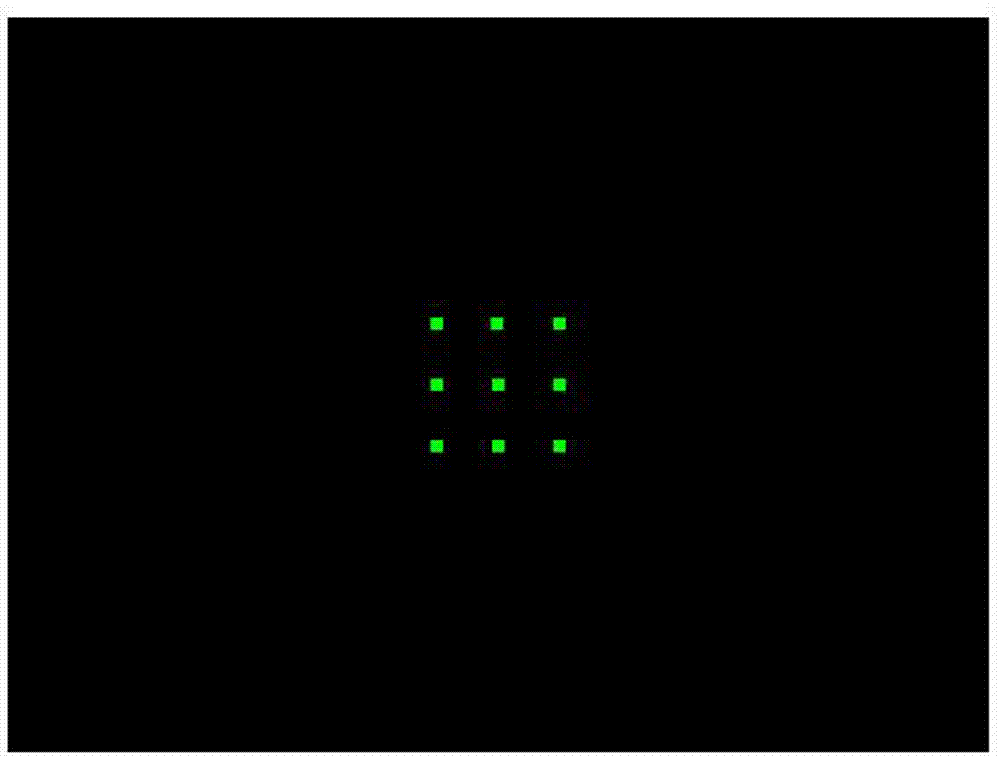

Automatic geometric correction method of surface projection based on image recognition

ActiveCN106534817BEasy to operateGood effectPicture reproducers using projection devicesDigital output to display deviceDot matrixBack calculation

The invention relates to an image-identification-based automatic geometric correction method for curved surface projection. A camera is arranged to face the center of a projection screen and is connected to a computer; a projector projects a projection image including at least four identifiable positioning green square blocks, the camera collects the image and identifies and localizes a color block position, and a homography matrix H between camera image space and projector image space is calculated; a full-black image is projected on the projector, N*N infrared laser pens are used for projection at horizontal and vertical equally-dividing points of a target projection region of the projection screen to form an N-row N-column laser dot matrix; the camera collects one frame of image, identifies the location of an infrared laser dot matrix location, and records a location set Cd{Cd1, Cd2...Cdi}; according to the homography matrix H, back calculation of a location set Ps of the intersection point location set Cd in the image space of the projector is carried out; a Bezier surface using as a projection curved surface is established in the image space of the projector by using opengl, the projection picture is mapped to the opengl Bezier surface in a texture manner, the location set Ps of the image space of the projector is used as N-row N-column control points of three-times Bezier surface to form a projection curved surface, thereby completing geometric correction. Therefore, non-linear curved surface geometric correction can be processed automatically; equipment is available; and the effect is good.

Owner:ZHENGZHOU J&T HI TECH

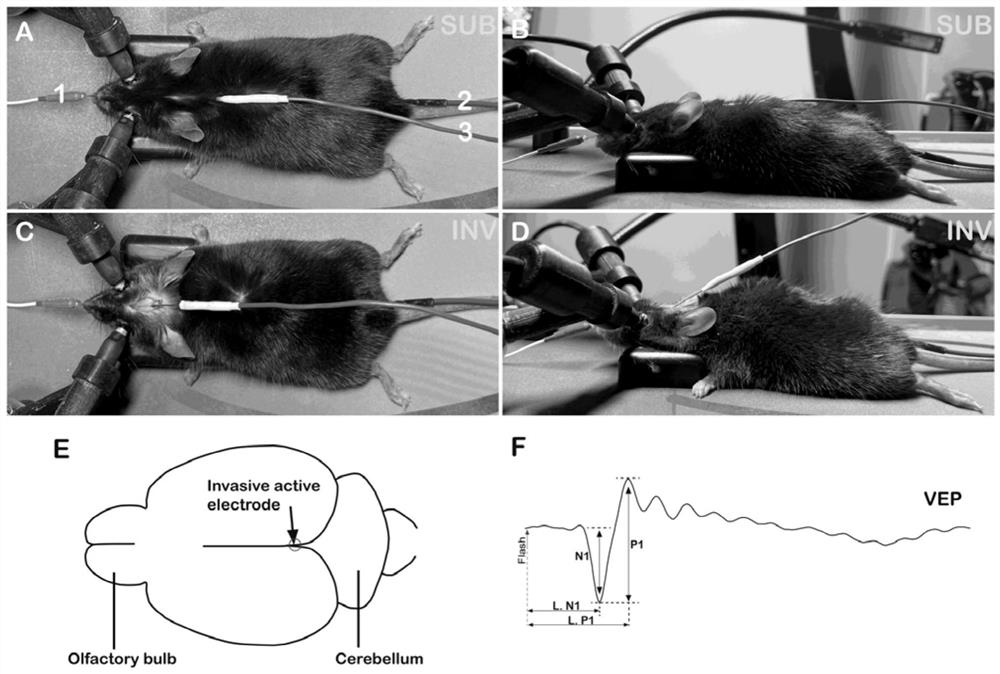

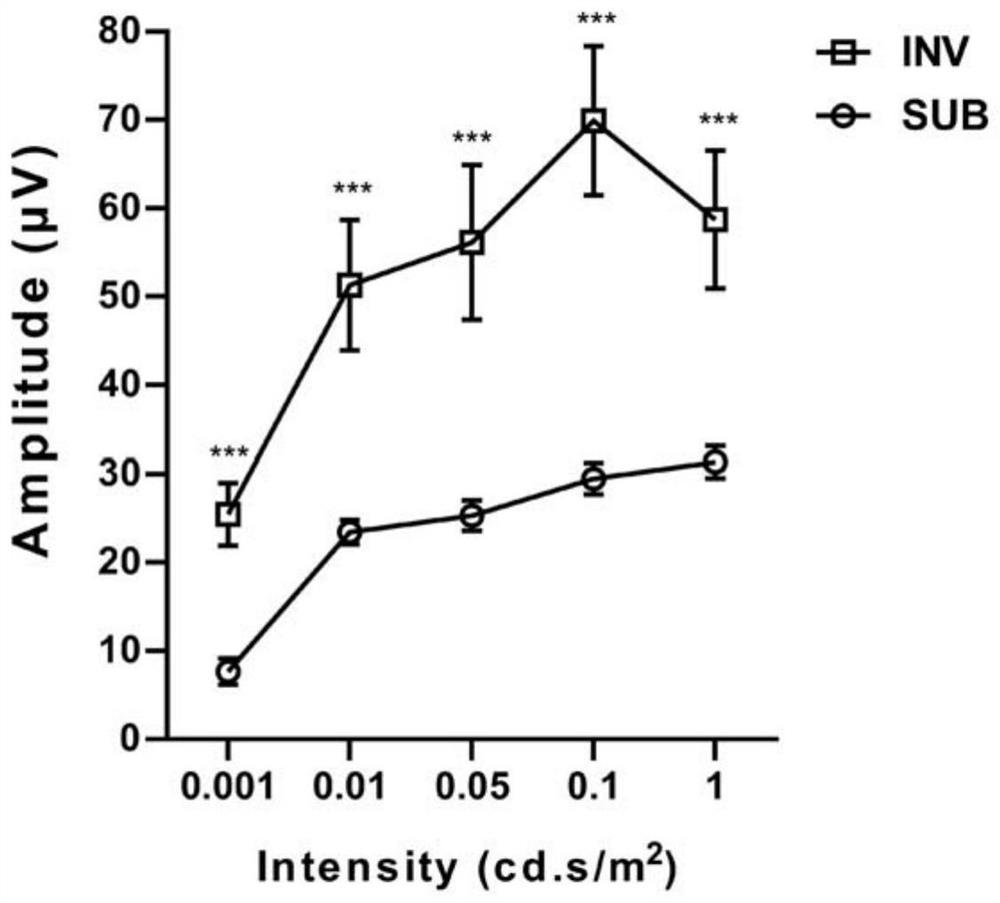

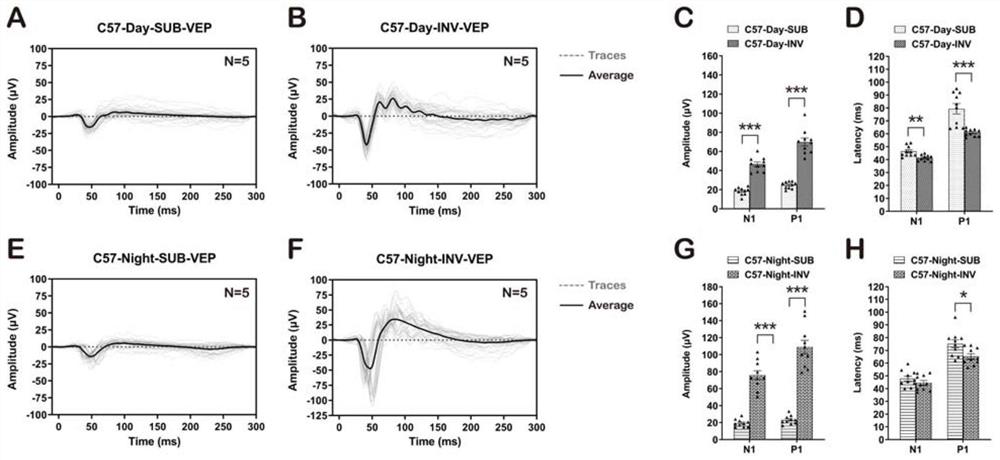

Novel mouse visual evoked potential recording method

PendingCN114711791ARecord waveform is goodLarge amplitudeDiagnostic recording/measuringSensorsVisual perceptionBrains tissue

The invention discloses a novel mouse visual evoked potential recording method. According to the method, the VEP with good waveform and large amplitude can be recorded, and the influence of the position of the active electrode on the VEP is large. In a C57 or CD1 optic nerve pinch injury model mouse with retinal ganglion cell deletion and a Brn3bAP / AP mutant mouse, the VEP amplitude is obviously reduced. The method disclosed by the invention is very reliable and stable, and is particularly suitable for detecting visual response of reduced RGC quantity, dysfunction or brain connection disorder. Compared with an existing subcutaneous method (SUB), the method has the advantages that the VEP which is relatively stable, good in waveform and larger in amplitude can be recorded; compared with a skull pre-implantation screw recording method, the method has the advantage that damage of pre-implantation screws to mouse brain tissues can be reduced.

Owner:向孟清

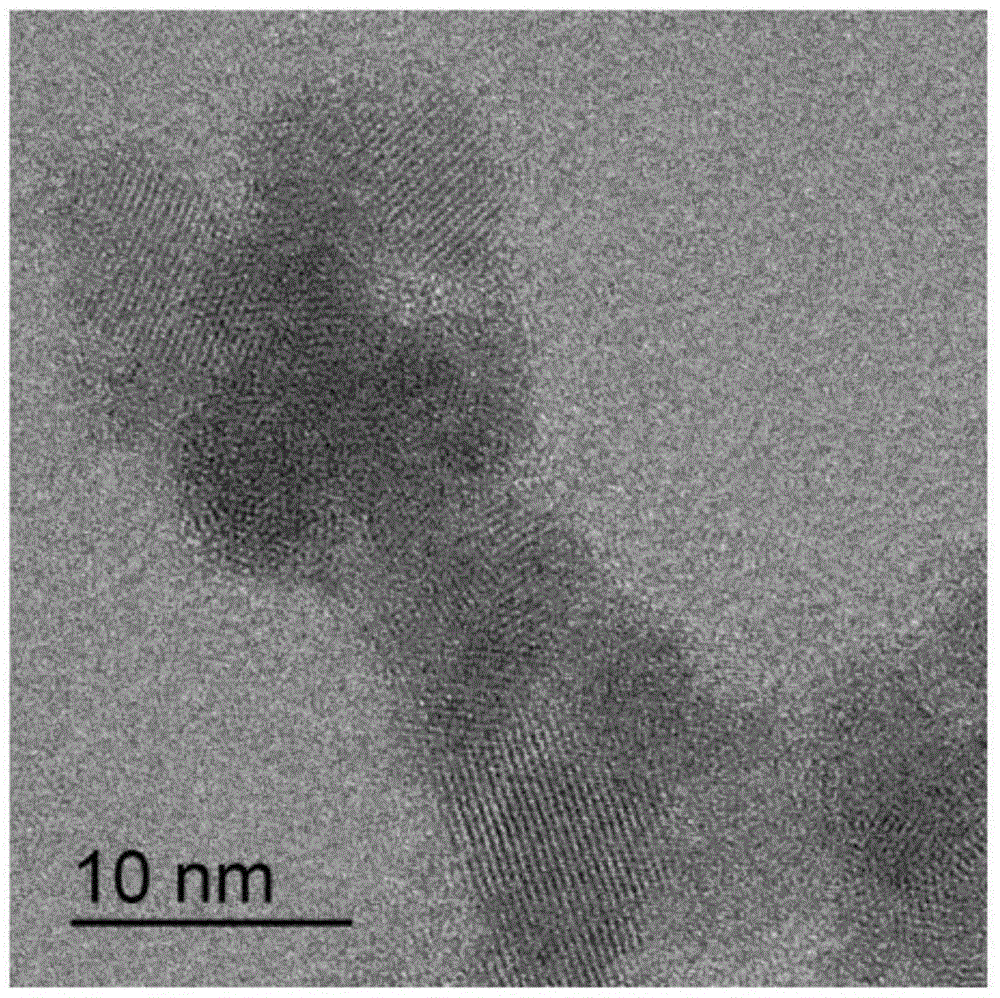

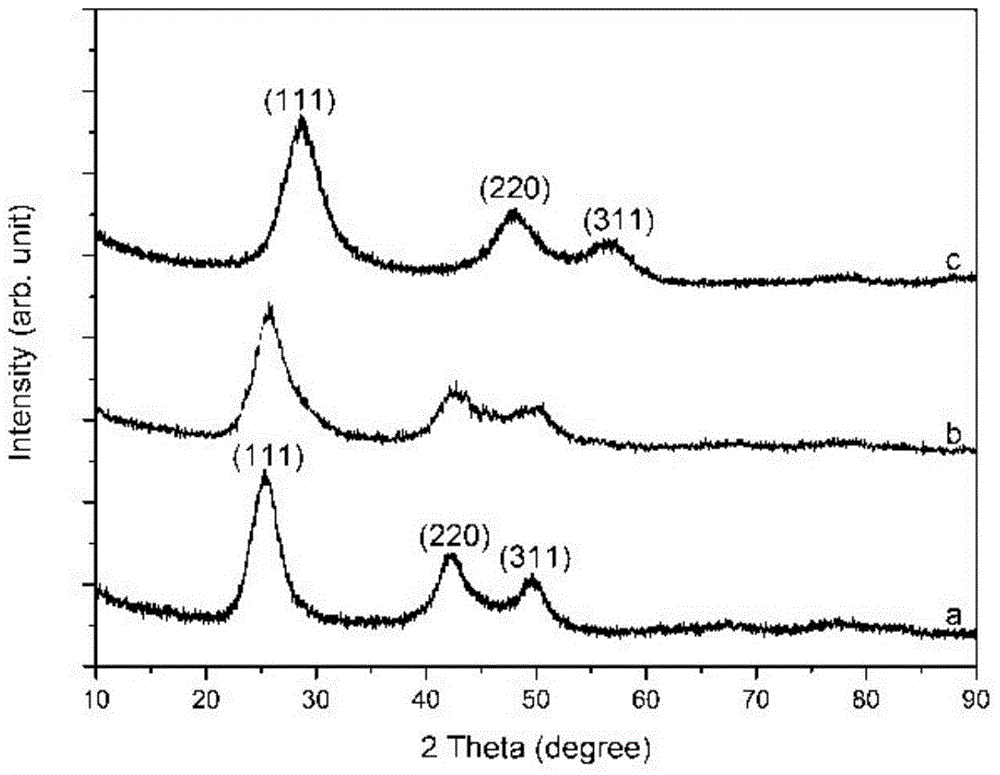

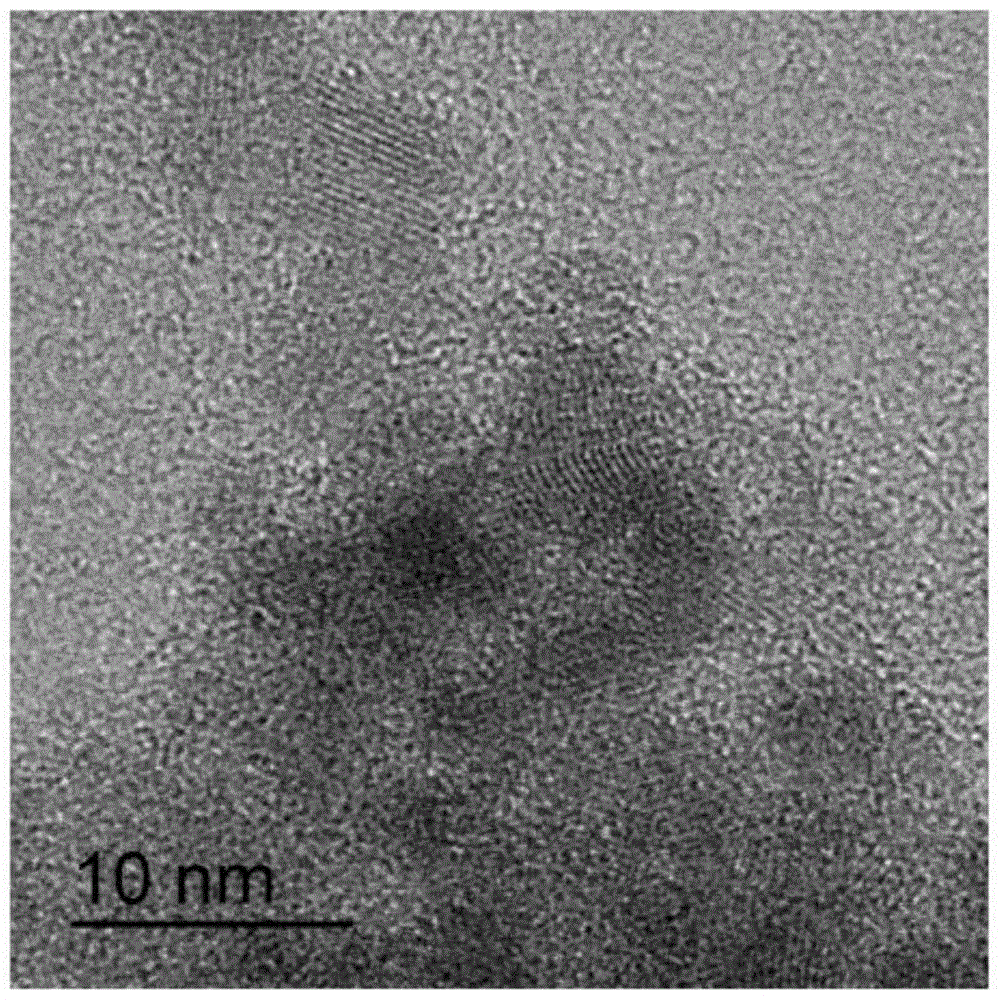

A doped core-shell nanomaterial and preparation method thereof

InactiveCN105271368BLower requirementEasy to operateMaterial nanotechnologyZinc sulfidesSurface finishCentrifugation

The invention discloses a doped core-shell nanometer material and a preparation method thereof. The chemical general formula of the material is Cd1-xMxSe / ZnS, and M is one of Cr, Mn, Fe, Co, Ni, Cu, Zn, Bi, Ce, Pr, Nd, Eu and Er. The preparation method comprises the steps that 1, a positive ion aqueous solution is prepared, a surface finishing agent is added, the pH value is adjusted, and positive ion precursor liquid is obtained; 2, Se powder is added to a NaBH4 aqueous solution, a reaction is carried out under protection of nitrogen, and negative ion precursor liquid is obtained; 3, at constant temperature, the negative ion precursor liquid and the positive ion precursor liquid are mixed for reacting, and core layer Cd1-xMxSe nanocrystalline precursor liquid is obtained; 4, a Zn<2+> and S<2-> ion aqueous solution is added through titrimetry, the reaction continues to be carried out, cooling is carried out under protection of nitrogen, detergent is added for centrifugation and washing, and the doped core-shell nanometer material is obtained. The material is free of toxins or low in toxin, and the preparation method is simple in step; the size is easy to control, and large-scale production can be achieved. A novel method is provided for preparing efficient and cheap biomedical materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Streptococcus suis sbp_bac_5 gene deletion strain and its construction method and application

ActiveCN104762244BTargetedWeak toxicityAntibacterial agentsBacterial antigen ingredientsBacteroidesBacilli

The invention discloses a Streptococcus suis SBP_bac_5 gene deletion strain as well as a construction method and application thereof. The deletion strain is SSΔSBP_bac_5 without resistance marker, and the preservation number is: CGMCC No.10076. The invention adopts the RecA homologous recombination system and uses the temperature-sensitive suicide plasmid pSET4s as a carrier to knock out the gene encoded by the Streptococcus suis type 7 strain SBP_bac_5, and destroys the expression of the SBP_bac_5 protein. The S. suis 7 type SS△SBP_bac_5 strain obtained by the invention is weaker in toxicity than the parent strain and safe for animals. Vaccines were made with recombinant bacteria and CD1 mice were immunized. The experimental results showed that the recombinant Streptococcus suis vaccine could effectively induce the body to produce a specific humoral immune response, so that the immunized mice could obtain protection against S. suis challenge, and could Effectively prevent the proliferation of bacteria in the body. The engineering bacterium obtained by the invention provides an important basis for the development of the Streptococcus suis vaccine.

Owner:HARBIN VETERINARY RES INST CHINESE ACADEMY OF AGRI SCI

Radioresistant peptide mutant protein and its preparation and purification method

ActiveCN108484738BImprove stabilityEasy to storeBacteriaMicroorganism based processesMutated proteinMutant protein

The invention discloses a method for preparing and purifying a radioresistant peptide or a mutant protein thereof. The method can significantly improve the protein purity and is convenient for industrial production. The present invention also provides a radioresistant peptide mutein, which is based on the radioresistant peptide protein CBLB502, and replaces the amino acid sequence between the ND1 and CD1 domains, and the mutein has SEQ ID NO: The stability of the amino acid sequence shown in 2 is significantly better than that of the CBLB502 protein in the prior art.

Owner:ACADEMY OF MILITARY MEDICAL SCI +2

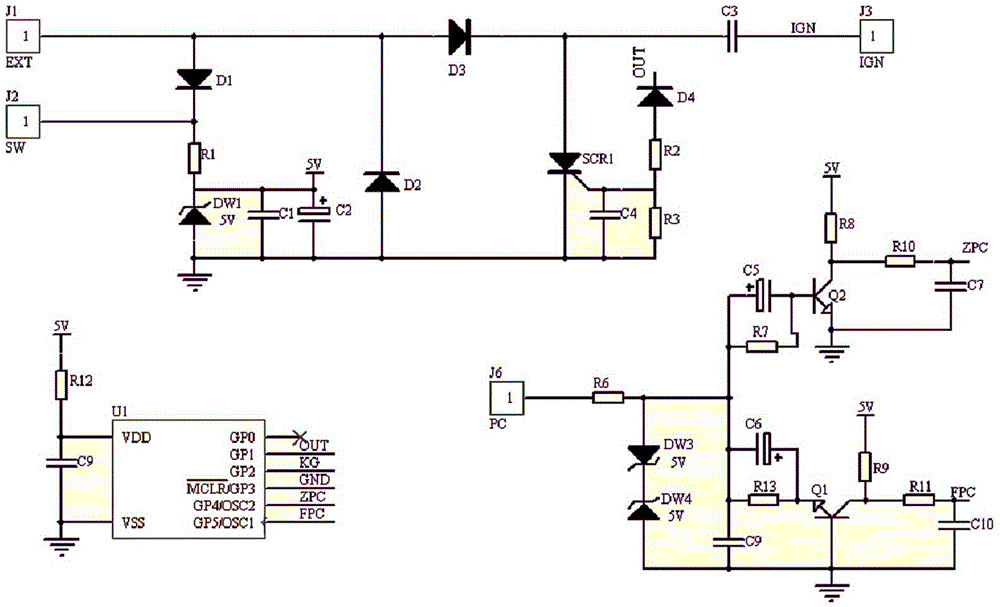

Integrated igniter control circuit

InactiveCN104110342BRealize the ignition functionReduce fuel consumptionIgnition automatic controlAutomatic controlMicrocontrollerIgnition coil

The invention discloses an integrated igniter control circuit; a magnetor provides alternating current, and then an ignition coil ignites through the integrated igniter control circuit. The integrated igniter control circuit comprises a microchip; the control circuit is connected to the output end of the ignition coil; when a positive pulse signal arrives, ZPC provides the signal to a single chip microcomputer; when a negative pulse signal arrives, FPC provides the signal to the single chip microcomputer; the single chip microcomputer processes the ZPC and FPC signal by the microchip to output an OUT signal so as to control a silicon controlled SCR1 to discharge positive electricity, so that energy stored in the capacitor C3 is released, and thereby the purpose of providing energy to the ignition coil is achieved, and low voltage (200V) is transformed to be high voltage (21KV) by the ignition coil to discharge to ignite oil and gas mixture in a gasoline engine, thus achieving the purpose of ignition; the microchip is added at the control part of the igniter, the igniter is under programmed control in a CD1 energy storage mode, and a curve for advance angles of ignition is traced out through programming according to power consumption of the engine, so that oil consumption is saved and ignition energy is large.

Owner:CHONGQING HUARI ELECTRICAL GOODS DEV

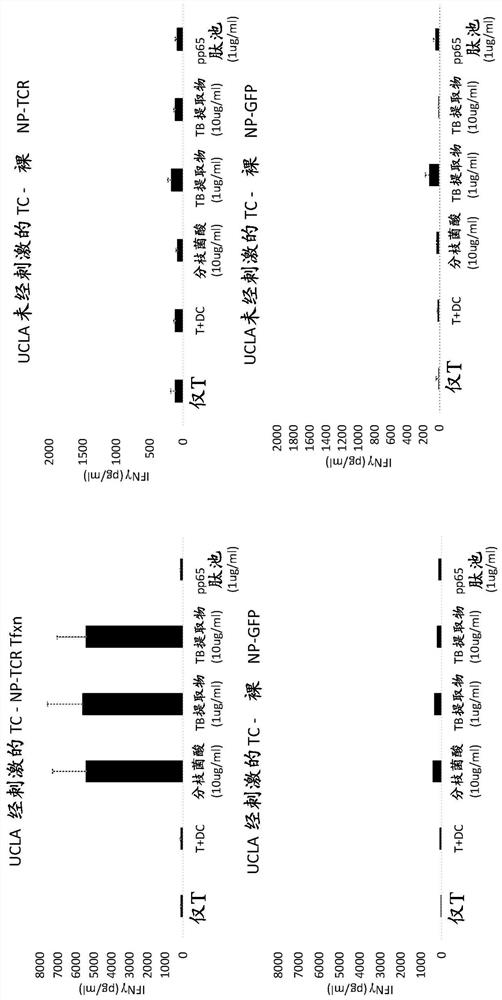

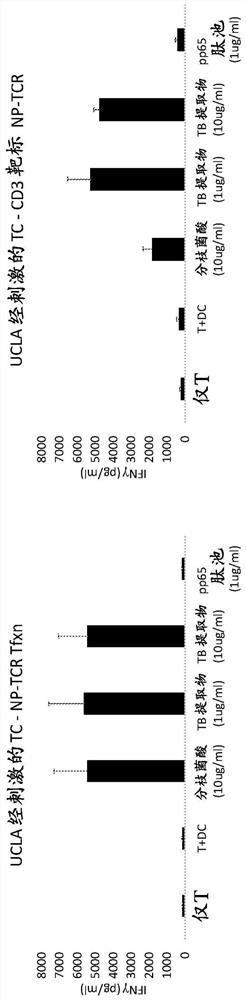

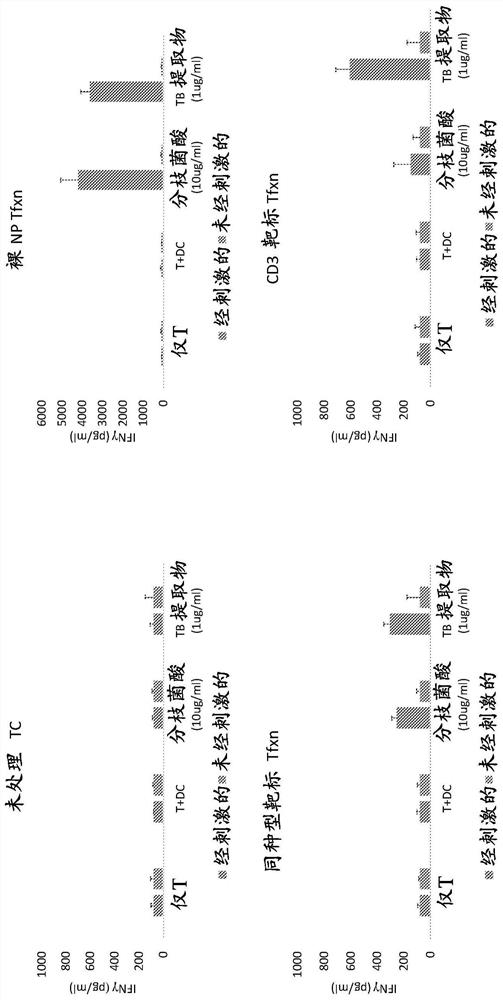

Recombinant cd1-restricted t cells and methods

PendingCN112805369AAntibacterial agentsImmunoglobulin superfamilyTreating tuberculosisCellular receptor

T cells are transfected with a recombinant RNA molecule that encodes at least one of an alpha chain and a beta chain of a CD1b restricted T cell receptor. Preferably, the so prepared T cells are used as a cell-based therapeutic composition to treat tuberculosis.

Owner:南特生物公司

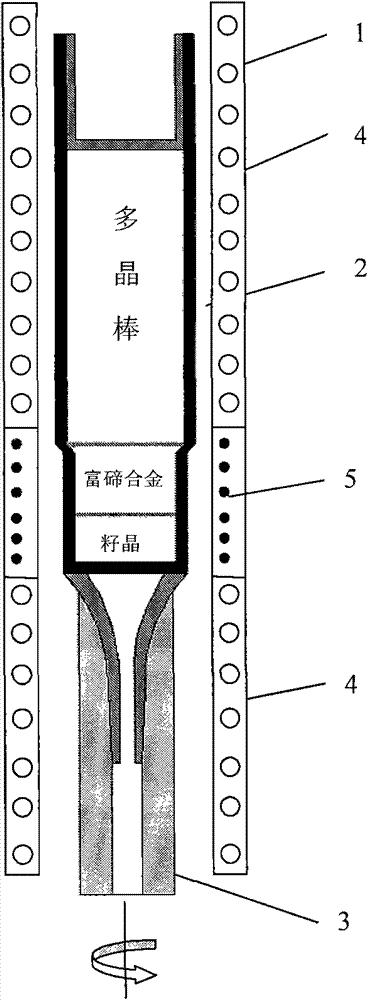

Method and device for growing cadmium zinc telluride crystals in mobile tellurium solvent melting zone

InactiveCN101871123BAchieve directed growthReduce contaminationPolycrystalline material growthBy zone-melting liquidsTe elementAlloy

The invention relates to a device and a method for growing cadmium zinc telluride crystals in a mobile tellurium solvent melting zone and belongs to the technical field of the growth of special crystals. The method is characterized by comprising the following steps of: feeding 99.99999 percent high-purity raw materials of which the stoichiometric proportion meets Cd1-xZnxTe (x=0.04-0.8) into two quartz tubes; adding 30 to 80 mass percent of excessive tellurium (Te) into one of the quartz tubes; vacuumizing and sealing the quartz tubes respectively and synthesizing materials in the quartz tubes to obtain polycrystalline rods and alloys rich in the Te in a rocking furnace; feeding seed crystals, the alloys rich in the Te and the polycrystalline rods into a long crystal tube, vacuumizing, sealing and placing the long crystal tube in a furnace body, wherein the alloys rich in the Te are positioned in a high-frequency induction heater at the temperature of 700 to 950 DEG C; raising the heater at a speed of 0.02 to 2mm / h and rotating the long crystal tube at the same time; and adding excessive Te in an alloy area rich in the Te to obviously reduce the melting point to ensure that the polycrystalline rods are continuously dissolved from the upper part of melt and cadmium zinc telluride single crystals are continuously precipitated from the lower part of the melt along with the rising. The method and the device for growing the cadmium zinc telluride crystals have the advantages of obviously reducing the growing temperature and the impurity concentration of the crystals.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com