Method and device for compressing free space in cadmium zinc telluride crystal growing crucible through double sealing sleeves

A free space, cadmium zinc telluride technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem of reducing the free space of quartz crucibles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

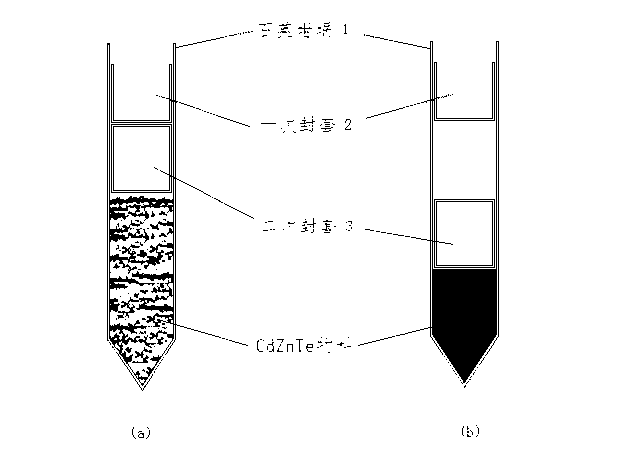

[0018] see figure 1 , used device among the present invention comprises high-purity quartz crucible 1, primary envelope 2, secondary envelope 3; The primary envelope 2 is a hollow high-purity quartz envelope with a section of opening, and the secondary envelope 3 is a hollow cylindrical high-purity quartz envelope, which maintains a certain degree of vacuum inside. Before and after material mixing, the secondary envelope 3 can be close to the CdZnTe material in the crucible.

[0019] The concrete processing step method of the present embodiment is as follows:

[0020] 1) will satisfy Cd 1-x Zn x Te (x=0.04~0.8) high-purity Cd, Zn, and Te raw materials with a purity of 99.99999% are put into a high-purity quartz crucible, put into two quartz envelopes in turn, and evacuated to 2.0×10 -4 Pa, use an oxyhydrogen flame to fuse the outer side of the envelope and the inner wall of the quartz crucible (the first time to seal the quartz tube).

[0021] 2) In this growth method, th...

Embodiment 2

[0024] In this embodiment, the same growth device as in the first embodiment above is used.

[0025] The growth process steps in this embodiment are completely the same as those in the first embodiment above, except that some process parameters are changed. The different process parameters are: the material temperature and holding time when the material is changed are 1135°C and 40h respectively.

[0026] The device and method for compressing the free space volume in the quartz crucible by using the double envelopes of the present invention have stable structure, simple operation and strong repeatability. The process of the present invention can effectively reduce the volume of free space in the quartz crucible during CdZnTe single crystal growth, limit the concentration of Cd vacancies in the obtained CdZnTe single crystal, and avoid the possibility of secondary charging of the material and the long crystal. Contaminated by impurities, high-quality, high-purity CdZnTe crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com