A doped core-shell nanomaterial and preparation method thereof

A core-shell nanomaterial and nanomaterial technology, which is applied in the field of nanomaterials and their preparation, can solve the problems of harsh reaction conditions, complicated reaction steps, and high cost, and achieves the advantages of good size controllability, good water solubility and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

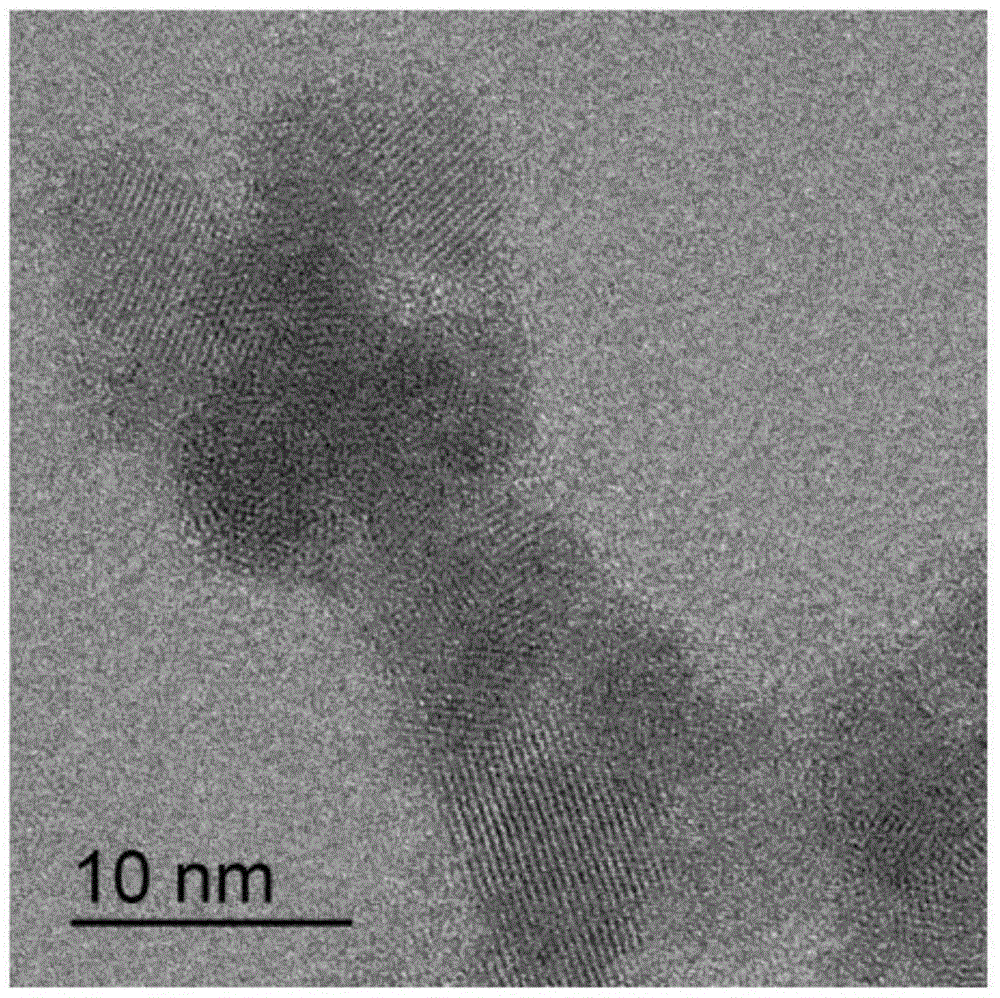

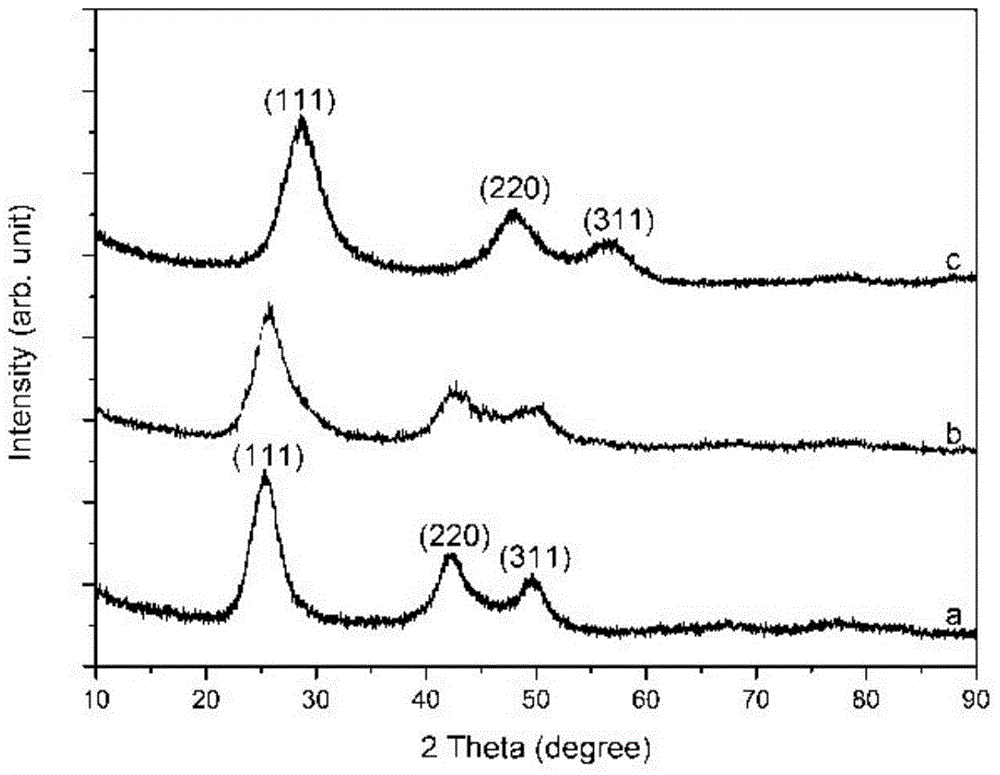

[0039] Cd 0.99 Cu 0.01 Preparation of Se / ZnS nanomaterials:

[0040] Step 1, take 0.0201g Cu(CH 3 COO) 2 ·H 2 O and 2.6787g Cd(CH 3 COO) 2 2H 2 O, dissolved in 30mL high-purity water at the same time, under the protection of nitrogen, add 1328uL mercaptoacetic acid, adjust the pH value to 10; obtain a cationic aqueous solution;

[0041] Step 2: Add 30 mL of high-purity water into the three-necked bottle, fill it with nitrogen for protection, add 0.78 g of sodium borohydride, stir thoroughly to dissolve it, add 0.7904 g of selenium powder, and react at room temperature for 20 minutes to obtain an anion precursor;

[0042] Step 3. Under the protection of nitrogen, raise the temperature of the anion precursor solution and keep it at 100°C, add the cation aqueous solution in step 1 to the anion precursor solution, fully stir, and react for 60 minutes to obtain the nuclear layer nanomaterial precursor solution; the stirring reaction The speed is 300r / min;

[0043] Step fou...

Embodiment 2

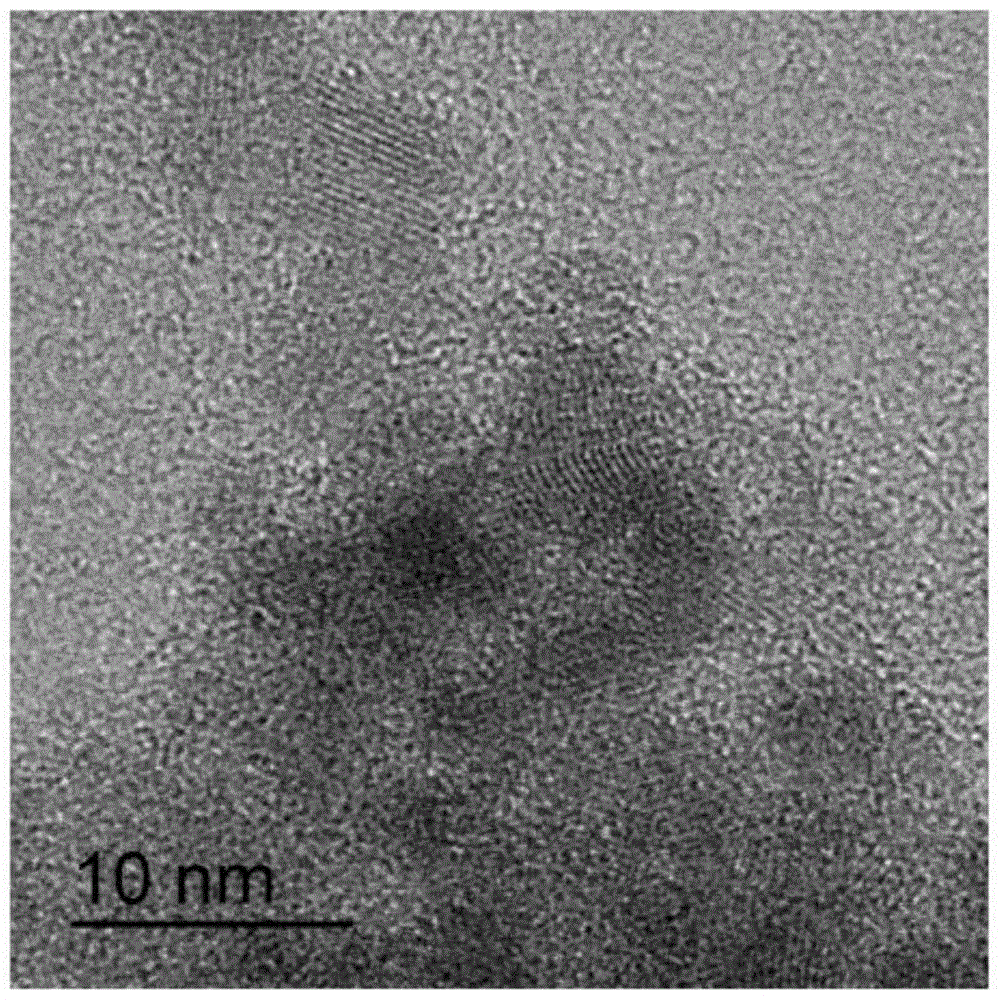

[0055] Cd 0.99 co 0.01 Preparation of Se / ZnS nanomaterials:

[0056] Step 1, take 0.0125g Co(CH 3 COO) 2 4H 2 O and 1.1584g Cd(CH 3 COO) 2 2H 2 O, dissolved in 20mL high-purity water at the same time, under nitrogen protection, add 1mL 3-mercaptopropionic acid, adjust the pH to 9, and obtain a cationic aqueous solution;

[0057] Step 2: Add 20 mL of high-purity water into the three-necked bottle, fill it with nitrogen for protection, add 0.386 g of sodium borohydride, stir well to dissolve it, add 0.3952 g of selenium powder, and react at room temperature for 15 minutes to obtain an anion precursor;

[0058] Step 3. Under nitrogen protection, raise the temperature of the anion precursor solution and keep it constant at 90°C, add the cation aqueous solution in step 1 to the anion precursor solution, fully stir, and react for 50 minutes to obtain the nuclear layer nanomaterial precursor solution; the stirring reaction The speed is 300r / min;

[0059] Step four, take 0.92...

Embodiment 3

[0061] Cd 0.95 Zn 0.05 Preparation of Se / ZnS nanomaterials:

[0062] Step 1, take 0.1112g Zn(CH 3 COO) 2 2H 2 O and 2.6677g Cd(CH 3 COO) 2 2H 2 O, dissolved in 20mL high-purity water at the same time, under the protection of nitrogen, add 4350uL glutathione, adjust the pH value to 9, and obtain a cationic aqueous solution;

[0063] Step 2. Add 50mL of high-purity water into the three-necked bottle, fill it with nitrogen for protection, add 0.9264g of sodium borohydride, stir well to dissolve it, add 0.9485g of selenium powder, and react at room temperature for 30 minutes; obtain anion precursor solution;

[0064] Step 3. Under nitrogen protection, raise the temperature of the anion precursor solution and keep it constant at 120°C, add the cation aqueous solution in step 1 to the anion precursor solution, stir fully, and react for 60 minutes to obtain the nuclear layer nanomaterial precursor solution; the stirring reaction The speed is 300r / min;

[0065] Step 4, get 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com