Luminescent material with core-shell structure and preparation method thereof

A technology of luminescent materials and core-shell structure, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of rare earth ion excitation peak line width narrow, low optical absorption cross-section, etc., achieve excellent light conversion performance, high luminous efficiency, luminous high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

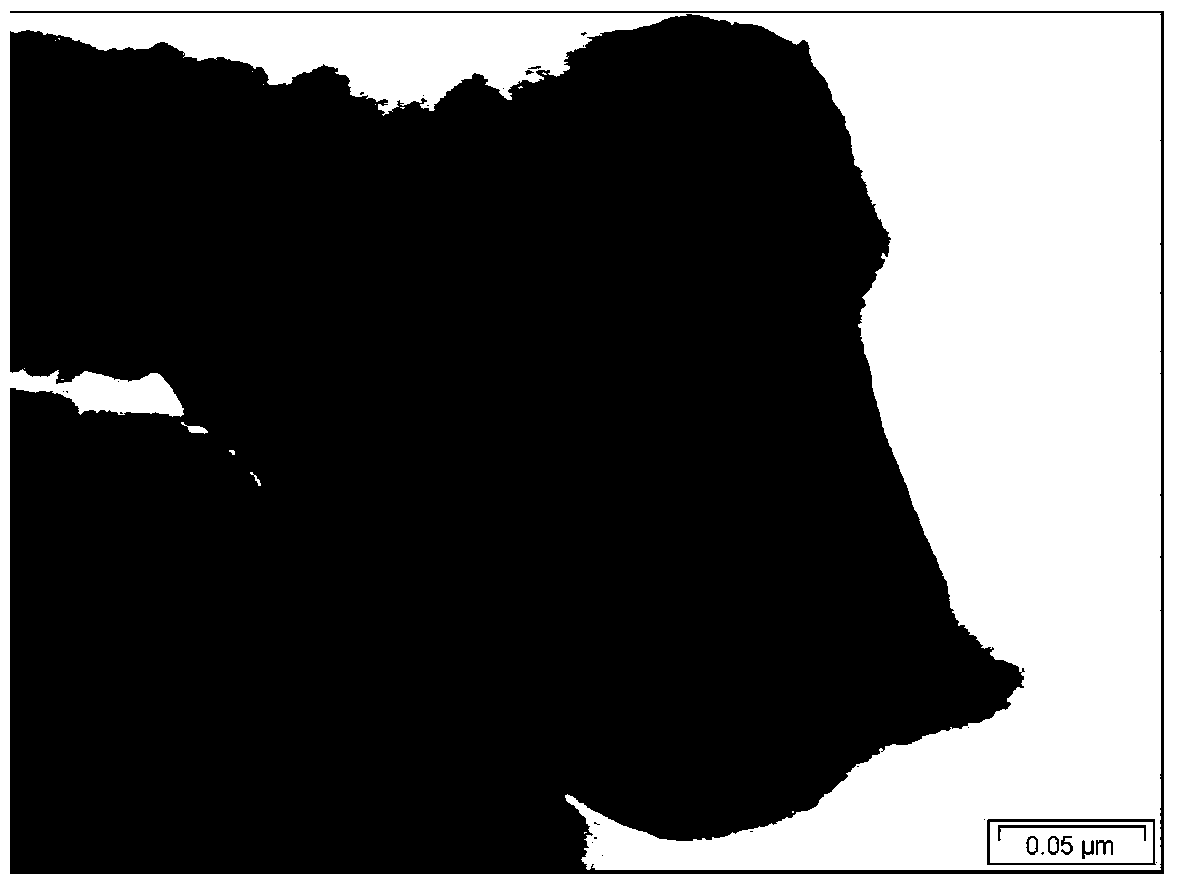

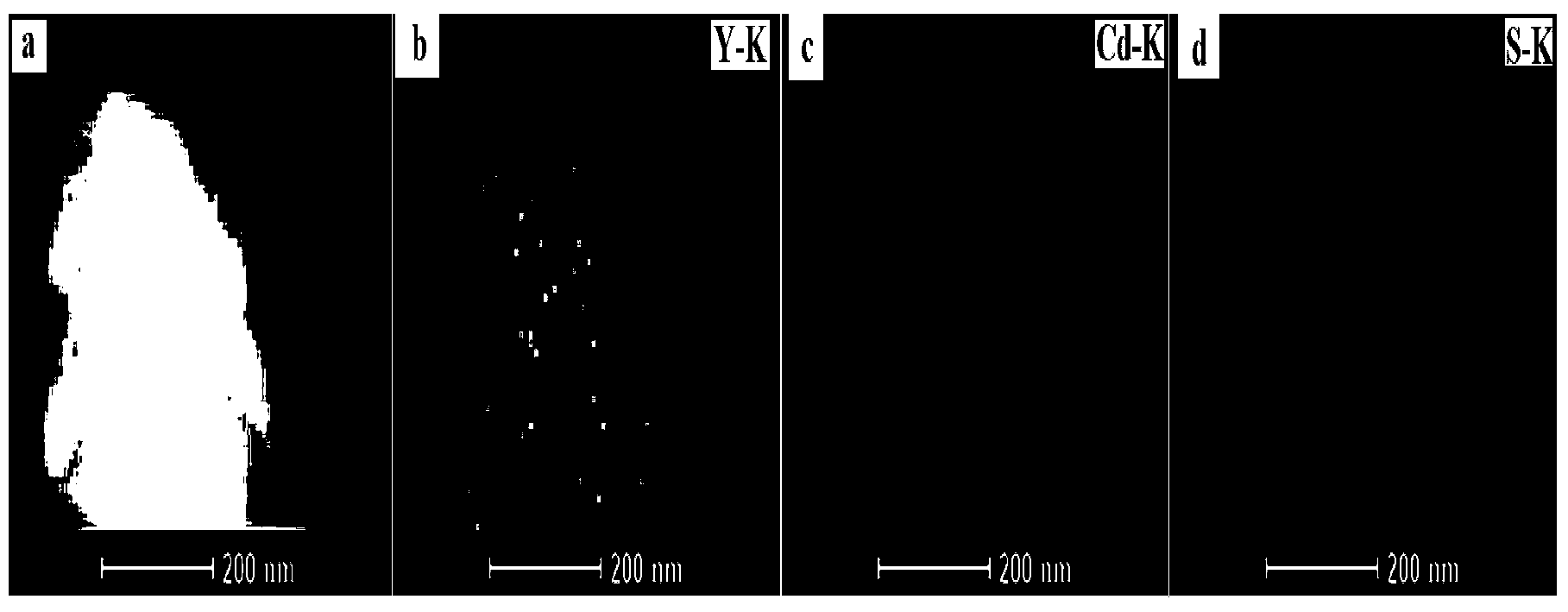

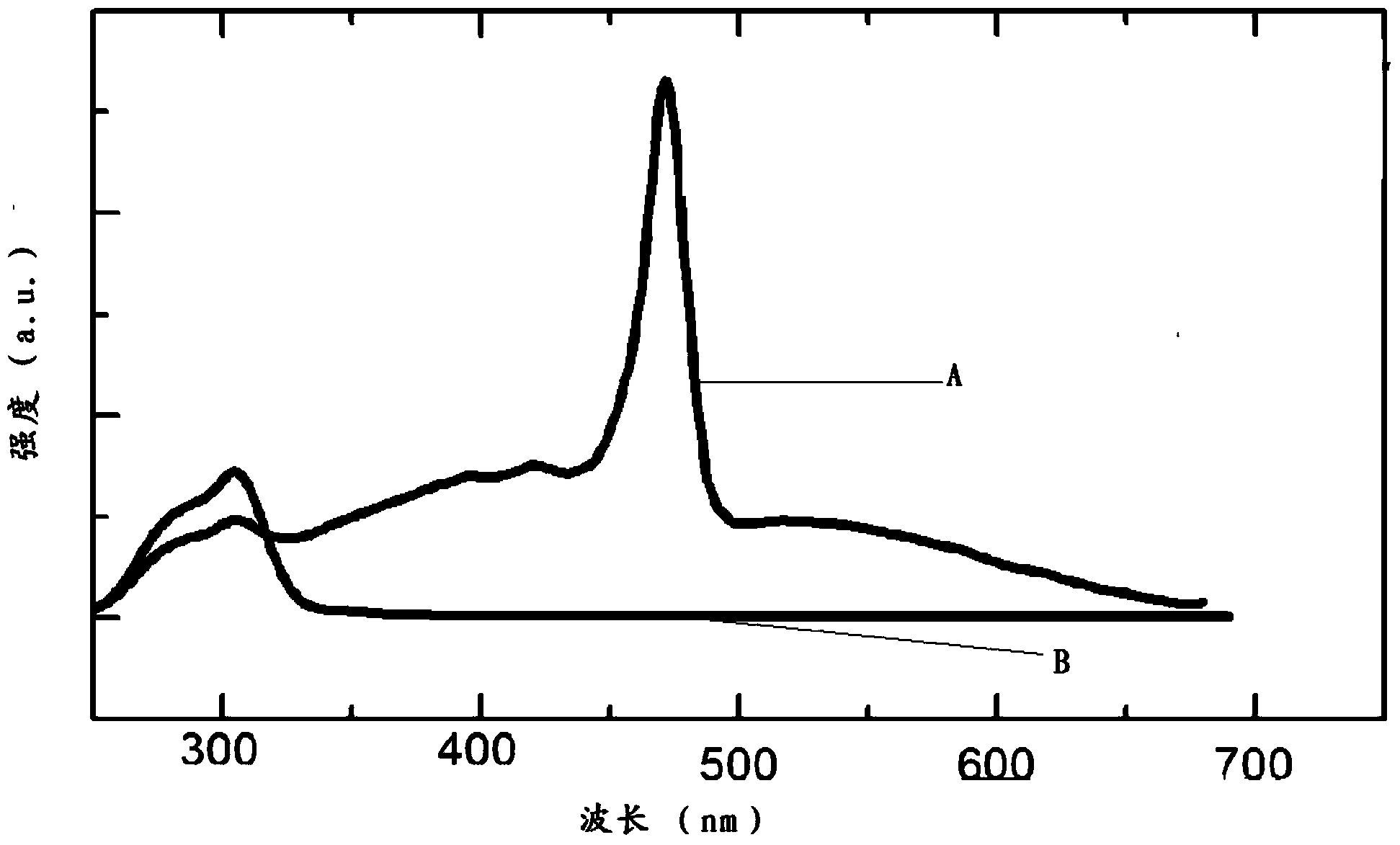

Image

Examples

preparation example Construction

[0029] The invention also discloses a method for preparing a luminescent material with a core-shell structure, comprising the following steps:

[0030] (A) Combining rare earth luminescent materials with semiconductor Cd 1-x Zn x After S is mixed, it is hot-pressed and sintered to obtain an intermediate; 0≤X<1;

[0031] (B) heat-treating the intermediate under the protection of an inert gas, and obtaining a luminescent material with a core-shell structure after annealing.

[0032] The present invention uses rare earth luminescent materials and semiconductor materials as raw materials, and the rare earth luminescent materials use rare earth ions as luminescent centers, and the rare earth ions are preferably trivalent lanthanides (Ln 3+ )ion. The rare earth luminescent material is preferably Y 0.91 Tb 0.01 Yb 0.08 o 3 , Y 0.89 Tb 0.01 Yb 0.08 Li 0.02 o 3 , Y 0.91 Tb 0.01 Yb 0.06 Li 0.02 o 3 , Y 0.89 T m 0.01 Yb 0.08 Li 0.02 o 3 , YLiF 4 : (Pr, Yb) etc. con...

Embodiment 1

[0039] Incorporate high-purity rare earth oxides including Y 2 o 3 ,Yb 2 o 3 ,Tb 4 o 7 Heat treatment at 800 degrees Celsius for 3 hours, weigh the rare earth oxide and lithium carbonate, etc., according to the molar ratio of the target phosphor components, and dissolve them in dilute nitric acid, adjust the pH value of the solution to make it between 2-4, heat and stir until The solution is clear and transparent. Then add citric acid (the ratio of citric acid to metal ion is 1:1), finally add polyethylene glycol, and stir to obtain a sol precursor solution. The precursor solution was transferred to an evaporating dish, dried at a constant temperature of 80 degrees Celsius for 10 hours, and dried. The obtained xerogel was pretreated on a heating plate at 200 °C to make it undergo self-propagating combustion. Grind, transfer to a corundum crucible, sinter at 500 degrees Celsius for 4 hours, and then sinter at 1000 degrees Celsius for 6 hours to finally get Y 0.91 Tb 0....

Embodiment 2

[0044] The molar ratio is 20mol% of Y 0.89 Tb 0.01 Yb 0.08 Li 0.02 o 3 with 80mol% Cd 0.8 Zn 0.2 S is fully ground and sieved under the protection of argon to achieve the purpose of uniform mixing and fine powder.

[0045] Select a mold with an inner diameter of 20mm to determine the amount of powder required.

[0046] Pad graphite paper in the mold; put the weighed 0.48g Y 0.89 Tb 0.01 Yb 0.08 Li 0.02 o 3 , 1.08gCd 0.8 Zn 0.2 S mixed powder into the mold cavity, so that the powder is evenly distributed in the mold cavity; put into the pressure head. Place the mold on the tablet press for pre-compression. Put the mold and pads into the hot-press sintering cavity in sequence. Move the lower ram upward to compress the graphite pad and mold. Adjust the temperature measuring device, and close the hot-press sintering chamber door. Vacuum to keep the air pressure in the cavity below 1Pa. Pressurize the mould, and the pressure is 90MPa. Start the program, start to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com