A kind of eva encapsulation adhesive film with light conversion effect

A technology for encapsulating adhesive films and effects, applied in adhesives, photovoltaic power generation, film/sheet adhesives, etc., can solve the problems of poor UV aging resistance, etc., and achieve extended service life, good light conversion effect, and UV resistance Effect of Photoaging Performance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare EVA encapsulating adhesive film A, be made up of the raw material of following mass parts:

[0024] ethylene vinyl acetate copolymer 100 parts,

[0025] 0.8 parts of tert-butyl peroxy 2-ethylhexyl carbonate,

[0026] 0.4 parts of three (2,4-di-tert-butylphenyl) phosphite,

[0027] 0.5 parts of 4,4'-dihydroxybenzophenone,

[0028] Sm(TTA)2(AA)Phen0.5 parts.

[0029] The above-mentioned raw materials are mixed evenly in proportion, and then the mixture is poured into an extruder for blending and extrusion, and the extruded product is cast, cooled, shaped in an oven, drawn, and coiled to obtain the EVA packaging film A.

Embodiment 2

[0031] Prepare EVA encapsulating adhesive film B, be made up of the raw material of following mass parts:

[0032] ethylene vinyl acetate copolymer 100 parts,

[0033] 0.6 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane,

[0034] 0.3 parts of three (2,4-di-tert-butylphenyl) phosphite,

[0035] 1 part of 4,4'-dihydroxybenzophenone,

[0036] Sm(TTA)2(AA)Phen1.5 parts.

[0037] Mix the above raw materials uniformly in proportion, then pour the mixture into an extruder for blending and extrusion, and the extruded product is cast, cooled, shaped in an oven, drawn, and coiled to obtain the EVA packaging film B.

Embodiment 3

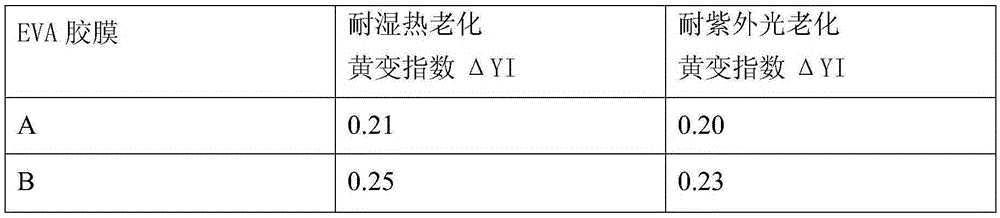

[0039] The EVA encapsulation adhesive film that embodiment 1 and 2 is made carries out following performance test:

[0040] 1. Performance test of UV aging:

[0041] According to the requirements of the International Electrotechnical Commission standard IEC61345, the ultraviolet radiation aging test was carried out. The test conditions are:

[0042] Sample surface temperature 65±5℃, test time 3000h

[0043] The wavelength is in the range of 280nm to 400nm, and the irradiation intensity is 1.5Kwh / m 2

[0044] The yellowing index (ΔYI) is analyzed according to GB2409-80 "Test Method for Yellowness Index of Plastics".

[0045] 2. Humidity and heat aging resistance

[0046] Damp heat aging test according to GB / T2423.3 test method

[0047] Test conditions: temperature 90°C, relative humidity 85%, time 3000h

[0048] The yellowing index (ΔYI) is analyzed according to GB2409-80 "Test Method for Yellowness Index of Plastics".

[0049] The results are shown in the table below: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com