Overhead power cable insulation material and production method thereof

A kind of insulating material, technology of power cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

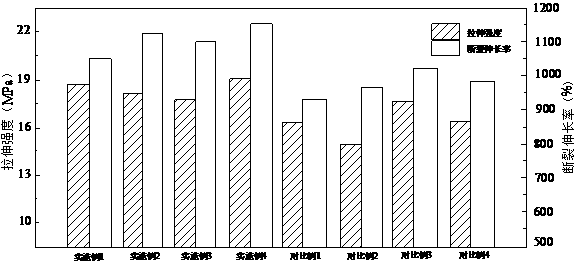

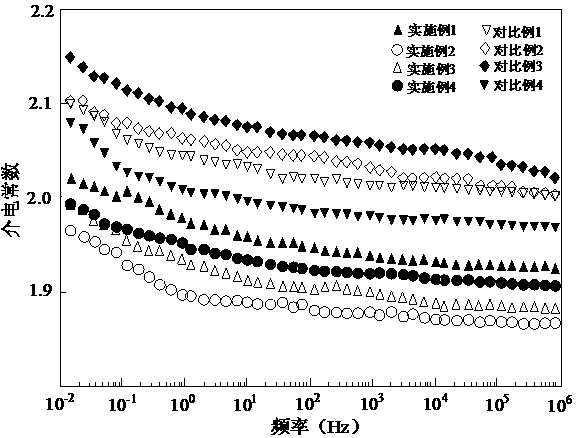

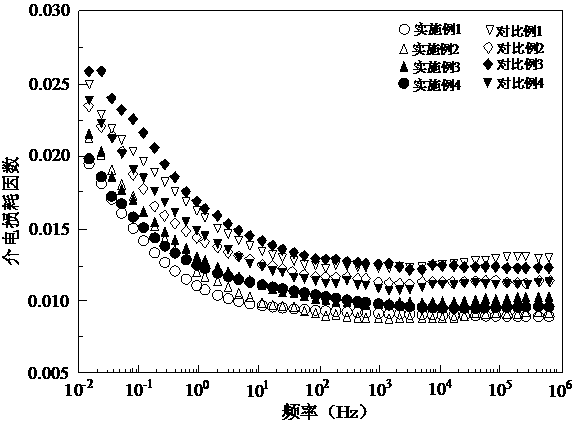

Embodiment 1

[0030] An insulating material for overhead power cables, made of the following raw materials in parts by weight: 100 parts of polyethylene, 10 parts of polypropylene, 3 parts of ethylene-vinyl alcohol copolymer, 0.2 part of benzil, 0.05 part of p-aminoazobenzene, 1 part of inorganic nanoparticles, 0.1 part of additives.

[0031] Polyethylene is composed of low-density polyethylene and high-density polyethylene with a mass ratio of 10:1. The inorganic nanoparticles are nano magnesium oxide. The average particle size of the inorganic nanoparticles is 10 nm. The additive is carbon black.

[0032] A production method for overhead power cable insulating material, comprising the following steps:

[0033] S1. Add polyethylene, polypropylene and ethylene-vinyl alcohol copolymer to the internal mixer, knead for 15 minutes, then add benzil and p-aminoazobenzene in sequence, continue kneading for 8 minutes, and then add inorganic nanoparticles Mixing with additives for 5 minutes to o...

Embodiment 2

[0037] An insulating material for overhead power cables, made of the following raw materials in parts by weight: 100 parts of polyethylene, 11 parts of polypropylene, 4 parts of ethylene-vinyl alcohol copolymer, 0.3 parts of benzil, 0.06 parts of p-aminoazobenzene, 2 parts of inorganic nanoparticles, 0.3 parts of additives.

[0038] Polyethylene is composed of low-density polyethylene and high-density polyethylene with a mass ratio of 12:1. The inorganic nanoparticles are nano zinc oxide. The average particle size of the inorganic nanoparticles is 12 nm. The additive is modified montmorillonite.

[0039] A production method for overhead power cable insulating material, comprising the following steps:

[0040] S1. Add polyethylene, polypropylene and ethylene-vinyl alcohol copolymer to the internal mixer, knead for 18 minutes, then add benzil and p-aminoazobenzene in sequence, continue kneading for 9 minutes, and then add inorganic nanoparticles Mixing with additives for 6 min...

Embodiment 3

[0044] An insulating material for overhead power cables, made of the following raw materials in parts by weight: 100 parts of polyethylene, 12 parts of polypropylene, 5 parts of ethylene-vinyl alcohol copolymer, 0.4 part of benzil, 0.07 part of p-aminoazobenzene, 3 parts of inorganic nanoparticles, 0.5 parts of additives.

[0045] Polyethylene is composed of low-density polyethylene and high-density polyethylene with a mass ratio of 15:1. The inorganic nanoparticles are nano-silica. The average particle size of the inorganic nanoparticles is 15 nm. The additive is UV absorber UV-531.

[0046] A production method for overhead power cable insulating material, comprising the following steps:

[0047] S1. Add polyethylene, polypropylene and ethylene-vinyl alcohol copolymer to the internal mixer, knead for 20 minutes, then add benzil and p-aminoazobenzene in sequence, continue kneading for 10 minutes, and then add inorganic nanoparticles Mixing with additives for 8 minutes to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com