A kind of anti-ultraviolet aging micro-surfacing mixture and preparation method thereof

A micro-surface compound, UV-resistant technology, applied in the field of road pavement, can solve the problems of affecting pavement durability, pavement temperature shrinkage cracking, etc., and achieve the effects of reducing low-temperature cracking, preventing catalytic degradation, and enhancing UV blocking ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

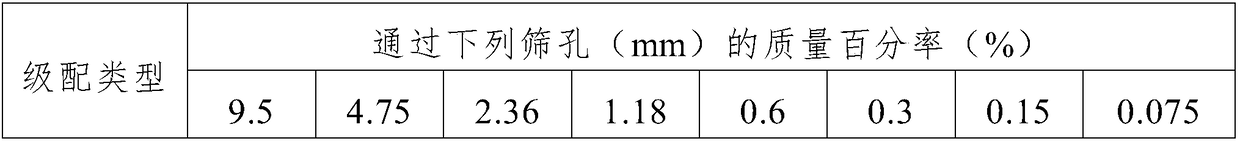

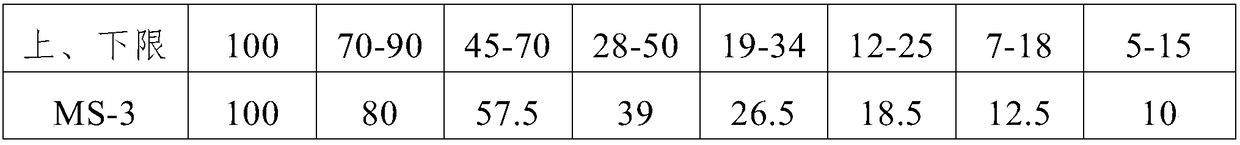

[0026] The anti-ultraviolet aging micro-surface mixture of this embodiment is made of the following raw materials in mass percentage: aggregate 77.0%, SBR modified emulsified asphalt 9%, mineral powder 4%, water 8%, cement 1.2%, nanometer dioxide 0.1% of cerium, 0.4% of carbon black, 0.3% of hydrotalcite; the nominal maximum particle size of the aggregate is not more than 9.5mm, and the particle size of the mineral powder is less than 0.075mm. The gradation type is MS-3 type, and the specific gradation composition is shown in Table 1;

[0027] Table 1 MS-3 type gradation design

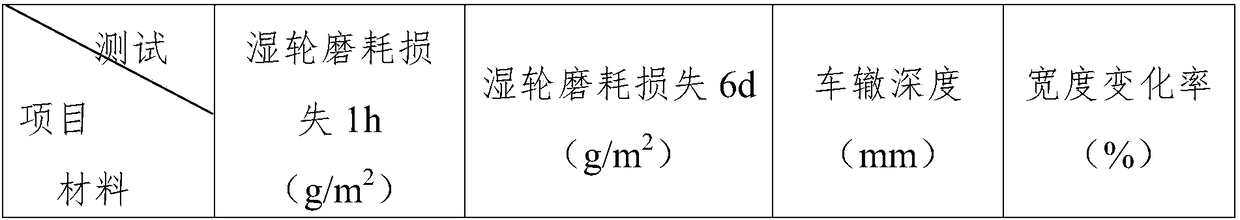

[0028]

[0029]

[0030] In the present embodiment, the mass purity of nano cerium dioxide is 99.8%, and the average particle diameter is 20nm, and carbon black is N220 type carbon black; 6 Al 2 (CO 3 )(OH) 16 4H 2 O. SBR modified emulsified asphalt is preferably formed by uniformly mixing base asphalt, SBR latex modifier, cationic asphalt emulsifier and water in a mass ratio of 60:5:3:32;...

Embodiment 2

[0036]The anti-ultraviolet aging micro-surface mixture of this embodiment is made of the following raw materials in mass percentage: 75.3% of aggregate, 8% of SBR modified emulsified asphalt, 5% of mineral powder, 9% of water, 1.8% of cement, and nanometer dioxide 0.2% of cerium, 0.6% of carbon black, 0.1% of hydrotalcite; the nominal maximum particle size of the aggregate is not more than 9.5mm, and the particle size of the mineral powder is less than 0.075mm. The gradation type is MS-3 type, and the specific gradation composition is shown in Table 1;

[0037] In the present embodiment, the mass purity of nano cerium dioxide is 99.8%, and the average particle diameter is 20nm, and carbon black is N220 type carbon black; 6 Al 2 (CO 3 )(OH) 16 4H 2 O. SBR modified emulsified asphalt is preferably formed by uniformly mixing base asphalt, SBR latex modifier, cationic asphalt emulsifier and water in a mass ratio of 60:5:3:32; For SK-70# asphalt, the emulsifier is MQK-1D slow...

Embodiment 3

[0043] The anti-ultraviolet aging micro-surface mixture of this embodiment is made of the following raw materials in mass percentage: 76.6% of aggregate, 8% of SBR modified emulsified asphalt, 5% of mineral powder, 8% of water, 1.4% of cement, and nanometer dioxide 0.3% of cerium, 0.2% of carbon black, 0.5% of hydrotalcite; the nominal maximum particle size of the aggregate is not more than 9.5mm, and the particle size of the mineral powder is less than 0.075mm. The gradation type is MS-3 type, and the specific gradation composition is shown in Table 1;

[0044] In the present embodiment, the mass purity of nano cerium dioxide is 99.8%, and the average particle diameter is 20nm, and carbon black is N220 type carbon black; 6 Al 2 (CO 3 )(OH) 16 4H 2 O. SBR modified emulsified asphalt is preferably formed by uniformly mixing base asphalt, SBR latex modifier, cationic asphalt emulsifier and water in a mass ratio of 60:5:3:32; For SK-70# asphalt, the emulsifier is MQK-1D slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com