High-bending-resistance wear-resistance and skid-resistance concrete for airdrome

A technology of high flexural resistance and concrete, applied in the field of civil engineering, can solve the problems of easy damage of anti-sliding structure, decrease of anti-sliding performance, structural damage, etc., achieve significant application value, improve wear-resistant and anti-sliding performance, increase resistance abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of high flexural and wear-resistant anti-skid concrete for airports, including cement, fly ash, sand, coarse aggregate and high-efficiency water reducer

[0031] (1) The relevant performance parameters of the above-mentioned components are as follows:

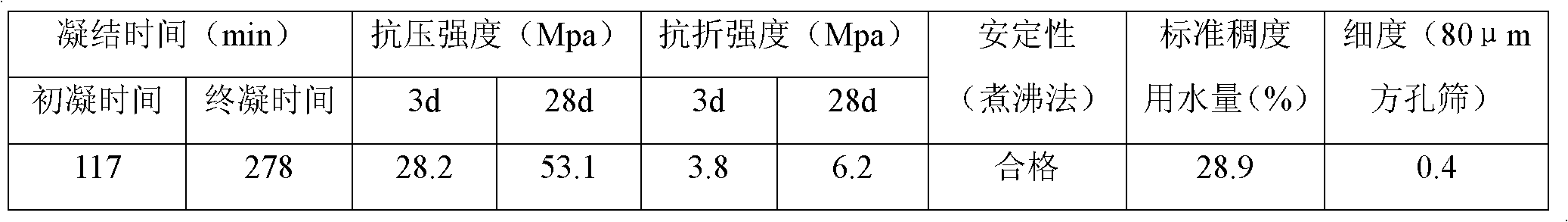

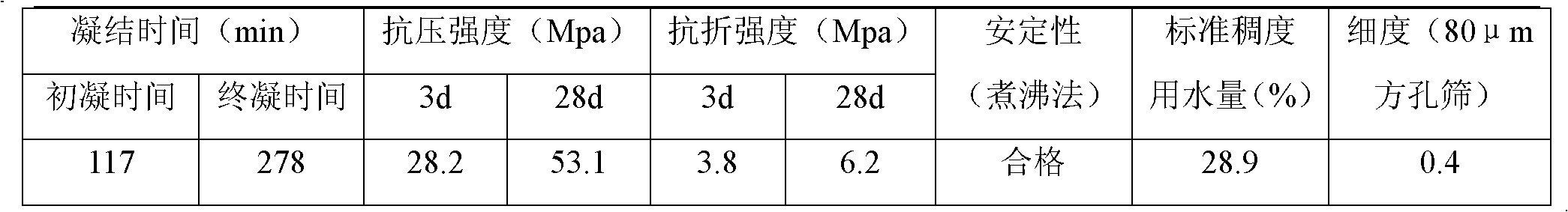

[0032] ① Cement: Anhui Conch P·I42.5 cement is used, and its physical and mechanical properties are shown in Table 1.

[0033] Table 1 Physical and mechanical properties of cement

[0034]

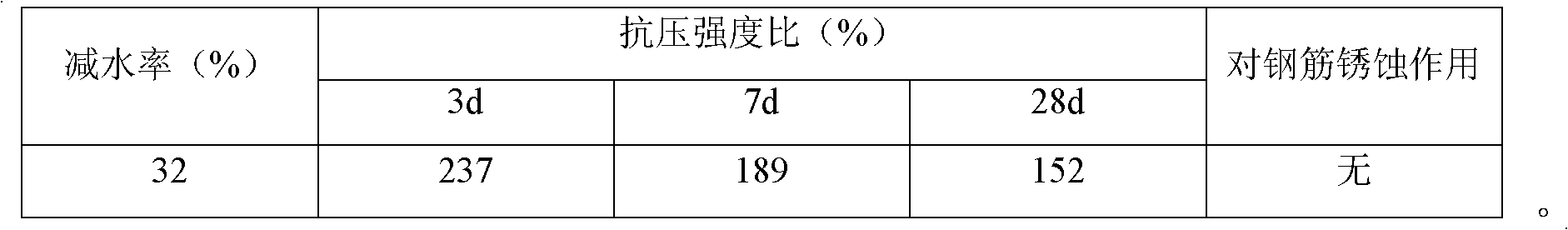

[0035] ② Fly ash: Zhenjiang Huayuan Class I fly ash is used, and its relevant technical parameters are shown in Table 2.

[0036] Table 2 Technical parameters of fly ash

[0037] Fineness (45μm square hole sieve)

[0038] ③Sand: Ganjiang mixed medium sand is used, and its relevant technical indicators are shown in Table 3.

[0039] Table 3 Technical indicators of sand

[0040] Fineness modulus

[0041] ④Coarse aggregate: Zhenjiang Chuanshan crushed stone (5-25mm) is used, and its relevant technical i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com