Microwave oven bakeware and manufacturing method thereof

A technology for microwave ovens and baking pans, which is applied in the field of microwave oven baking pans and its preparation, and can solve the problems of lack of frying taste, color and fragrance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 1) Weighing 30% of tetraacicular zinc oxide whiskers and 70% of ceramic glaze by weight percentage;

[0012] 2) Mix and stir the above-mentioned materials evenly to make the coating material for the outer surface of the microwave oven baking tray of Example 1;

Embodiment 2

[0014] 1) Weighing 70% of tetraacicular zinc oxide whiskers and 30% of ceramic glaze by weight percentage;

[0015] 2) Mix and stir the above-mentioned materials evenly to make the coating material for the outer surface of the microwave oven baking tray of Example 2;

[0016] Take the outer surface coating materials of the microwave oven baking trays obtained in the above-mentioned embodiments and put them into the spray gun, the mouth of the spray gun is 10-50cm away from the ceramic disc, and the coating material is sprayed on the outer surface of the ceramic disc by using an air pressure of 0.3-0.6Mpa , repeated spraying to make the coating thickness reach 1.5mm;

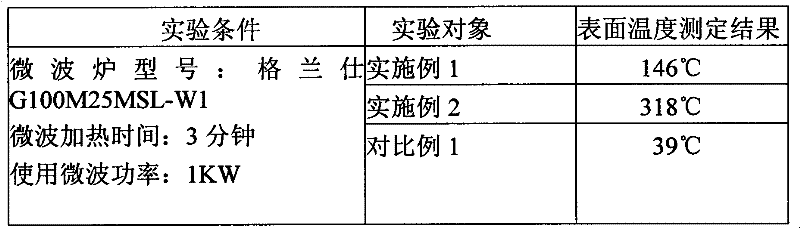

[0017] Put the sprayed ceramic dish into a kiln for sintering. The sintering temperature is 1360° C. and the sintering time is 24 hours. A microwave-absorbing heating layer is formed on the outer surface of the ceramic dish to make the microwave baking pan of Example 1 and the microwave oven of Example 2. bakewa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com