Gas isolation method used during drying of hot-blast stove in iron works

A technology for hot blast stoves and iron smelting plants, which is applied in the field of gas isolation of hot blast stoves, can solve the problems of reddening of hot blast branch pipe shells, damage to refractory fiber blankets, affecting normal production, etc., and achieves the effect of ensuring construction period and safe and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

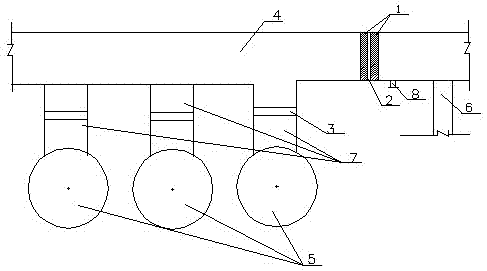

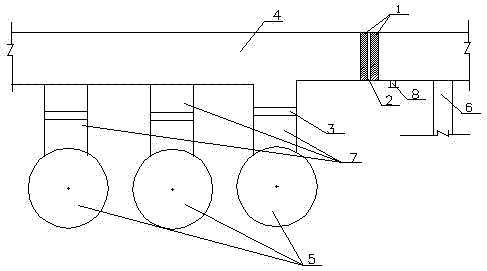

[0011] The method of gas isolation in the hot blast furnace of this ironworks has been successfully applied in the 1# and 2# 1780 m3 blast furnace projects of Jiujiang Steel Works and the 1080 m3 blast furnace project of Jiujiang Steel Works; the 1# and 2# 1780 m3 blast furnace projects of Jiujiang Steel Works The inner diameter of the hot air main pipe is 2368 mm, and the thickness of the left and right partition walls is 232 mm. The heat insulation layer between the left and right partition walls is a ceramic fiber blanket with a thickness of 10 mm. mm, the construction period was shortened by 25 days, and the cost was reduced by 330,000 yuan; the inner diameter of the hot blast main pipe of the 1080 m3 blast furnace project in Jiujiang Steel Plant was 2368 mm, and the thickness of the left and right partition walls was 232mm. The heat insulation layer between the left and right partition walls was ceramic fiber blanket. The thickness of the thermal layer is 10 mm, the refrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com