Composite crack control prestressed concrete big tube pile and manufacturing method thereof

A technology of composite materials and concrete, which is applied in the fields of bridge engineering, port engineering pile foundation and civil engineering. cracking, excellent impact resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

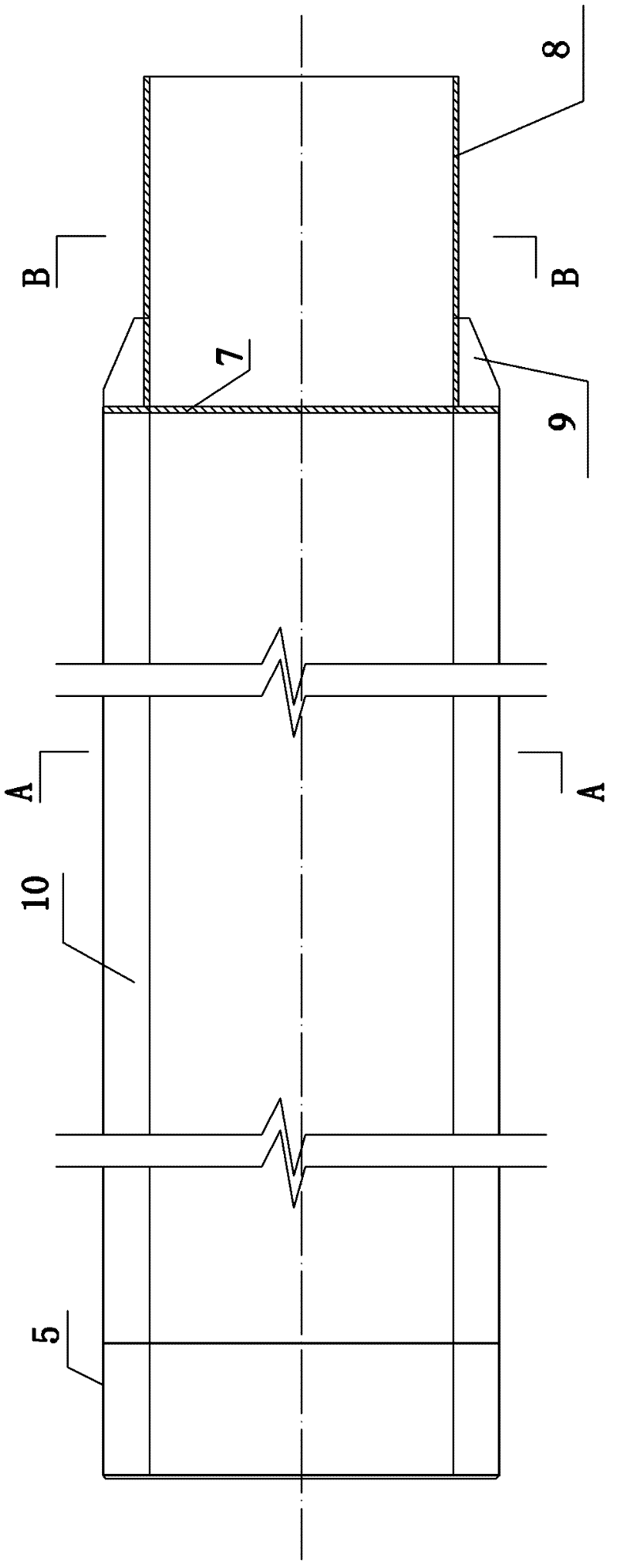

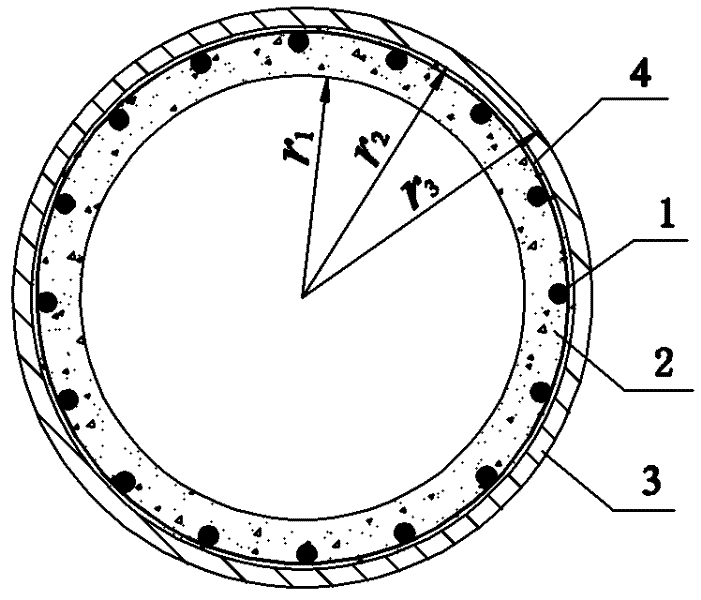

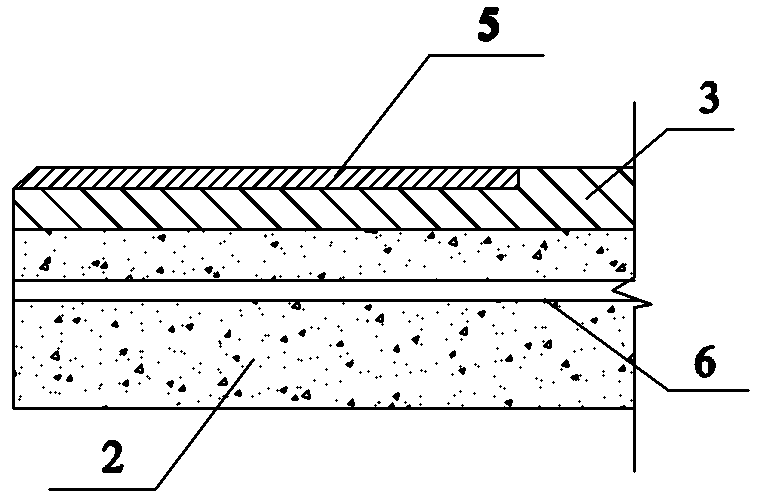

[0033]Refer to attached picture. A prestressed concrete large pipe pile with composite material crack control provided by the present invention includes a steel pipe pile tip 8 and several pipe joints; wherein, each pipe joint uses concrete 2 as the matrix, and the concrete outside the pipe pile is equipped with a UHTCC control pipe pile. Crack protective layer 3 to replace concrete 2, steel plate hoop 5 on the top periphery of pile top pipe joint, flange plate 7 on the bottom end of pile bottom pipe joint, spiral stirrup 4 inside the pipe wall, and reserved channels 6. The pipe joints are spliced together by stretching the longitudinal prestressed tendons 1 passing through the reserved channels 6, and the reserved channels 6 are filled and compacted with cement paste after the longitudinal prestressed tendons 1 are stretched. The steel pipe pile tip 8 is connected to the pile bottom pipe joint flange 7 by welding, and a stiffening plate 9 is provided at the intersection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com