Starting control method for hydrogen engines based on subsection control

An engine and hydrogen technology, applied in engine control, electrical automatic control, automatic control, etc., can solve problems affecting ignition, hydrogen injection control, abnormal combustion, crankshaft phase judgment errors, etc., to achieve accurate hydrogen injection ignition control, high The effect of controlling precision and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

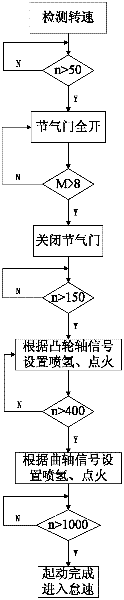

[0047] During the starting process of the engine, the rotational speed changes greatly. In order to improve the control accuracy, a segmented processing is carried out. See figure 2 , the specific starting control process includes the following steps:

[0048] Step 1. After the engine starts to start, detect the engine speed (that is, the crankshaft speed) in real time. When the speed is lower than 50 rpm, the calculation error of the single-chip microcomputer is caused because the speed is too low. Therefore, although the speed is calculated, hydrogen injection is not performed according to the speed. The ignition is set, nor does it control the throttle. Since the engine is started by the starter motor, the engine speed is higher than 50 rpm in a short period of time, so if the engine speed is lower than 50 rpm, no control will have a great impact on the engine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com