Fuel gas-steam combined cycle heat power plant

A combined cycle, gas-steam technology, used in steam generation, steam generation devices, combined combustion mitigation, etc., can solve the problem of not being able to supply all of them, and achieve the effect of simplified structure, flexible adjustability, and reduced maintenance and overhaul workloads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following examples.

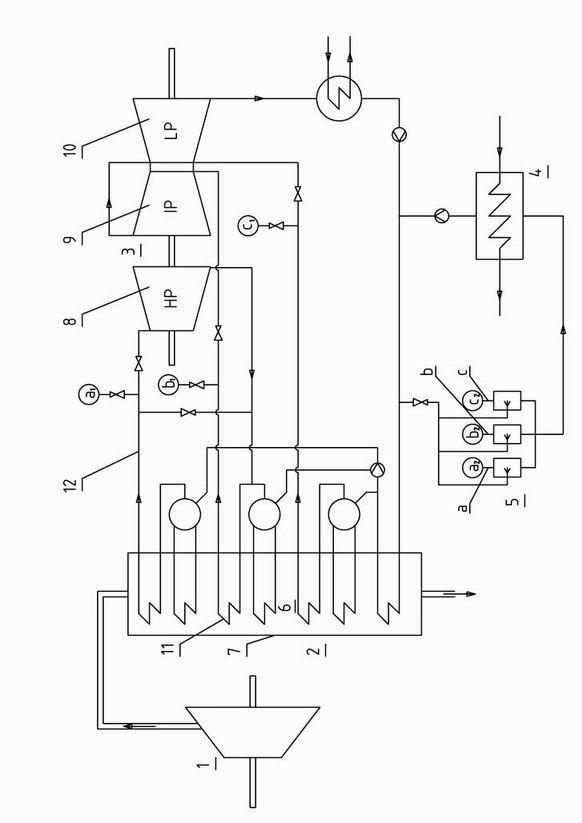

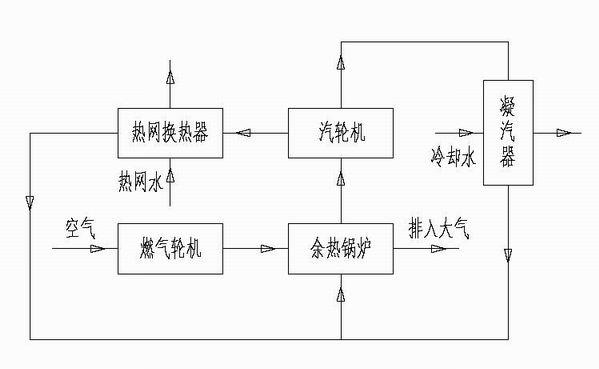

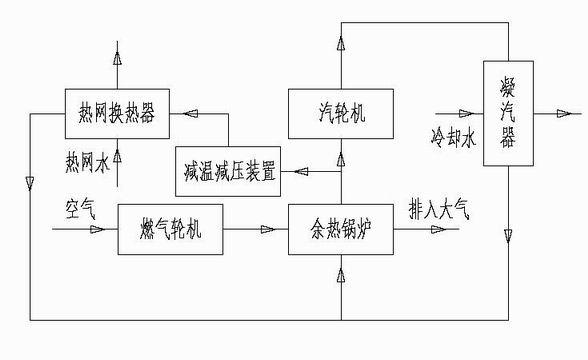

[0017] Such as figure 1 As shown, a gas-steam combined cycle thermal power plant includes a gas turbine 1 , a boiler 2 supplying steam for a steam turbine 3 or a heat network heat exchanger 4 , a steam turbine 3 and a heat network heat exchanger 4 . The boiler 2 has an exhaust passage 7 with a heat exchange surface 6 arranged therein. The passage 7 can be arranged substantially horizontally or substantially vertically, through which the exhaust gas of the gas turbine 1 passes.

[0018] The boiler 2 is connected to the steam turbine 3 and the heat network heat exchanger 4; the steam generated by the boiler 2 can be selectively provided to the steam turbine 3 or the heat network heat exchanger 4;

[0019] The pipes a, b, and c connecting the boiler 2 to the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com