Novel energy-saving boiler

A boiler and a new type of technology, applied in the field of boilers, can solve the problems such as the inability of the flue gas to flow smoothly, affect the operation effect of the boiler, and the limited heating area, and achieve the effects of avoiding easy coking, simple structure, and increasing the heating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

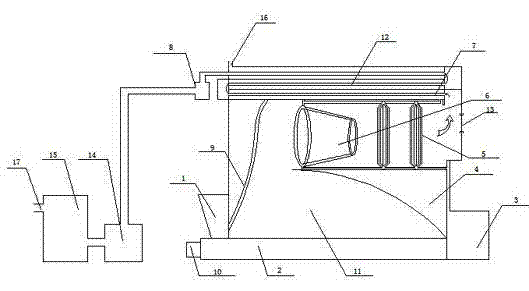

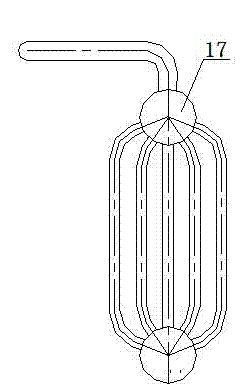

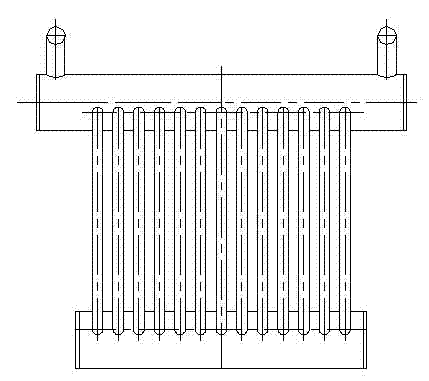

[0023] see figure 1 , the present invention comprises a furnace 11, a coal hopper 1 is arranged on one side of the furnace 11, a soot cleaning hole 13 is arranged on the other side, a fire grate 2 is arranged at the bottom of the furnace 11, and a blower 10 is arranged at one end of the fire grate 2. The furnace 11 is provided with a front arch 9 and a rear arch 4, the upper part of the furnace 11 is provided with a furnace 12, the furnace 12 is provided with a smoke pipe 7, the furnace 12 is filled with liquid, and the top of the furnace 12 is provided with a hot water outlet 16, Furnace liner 12 is connected to flue gas heat recovery device 14, and flue gas heat recovery device 14 is connected to triple-tower desulfurization and dust collector 15, and flue gas outlet 17 is opened on triple-tower desulfurization and dust collector 15. One side of the furnace 11 is provided with a cold water tank 3, and the furnace 11 is provided with a circular platform bell mouth 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com