Water heater adopting vacuum insulation panel to insulate heat and preserve heat

A technology of vacuum insulation panels and heat insulation, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., to achieve excellent heat insulation, reduce energy consumption, and excellent heat insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

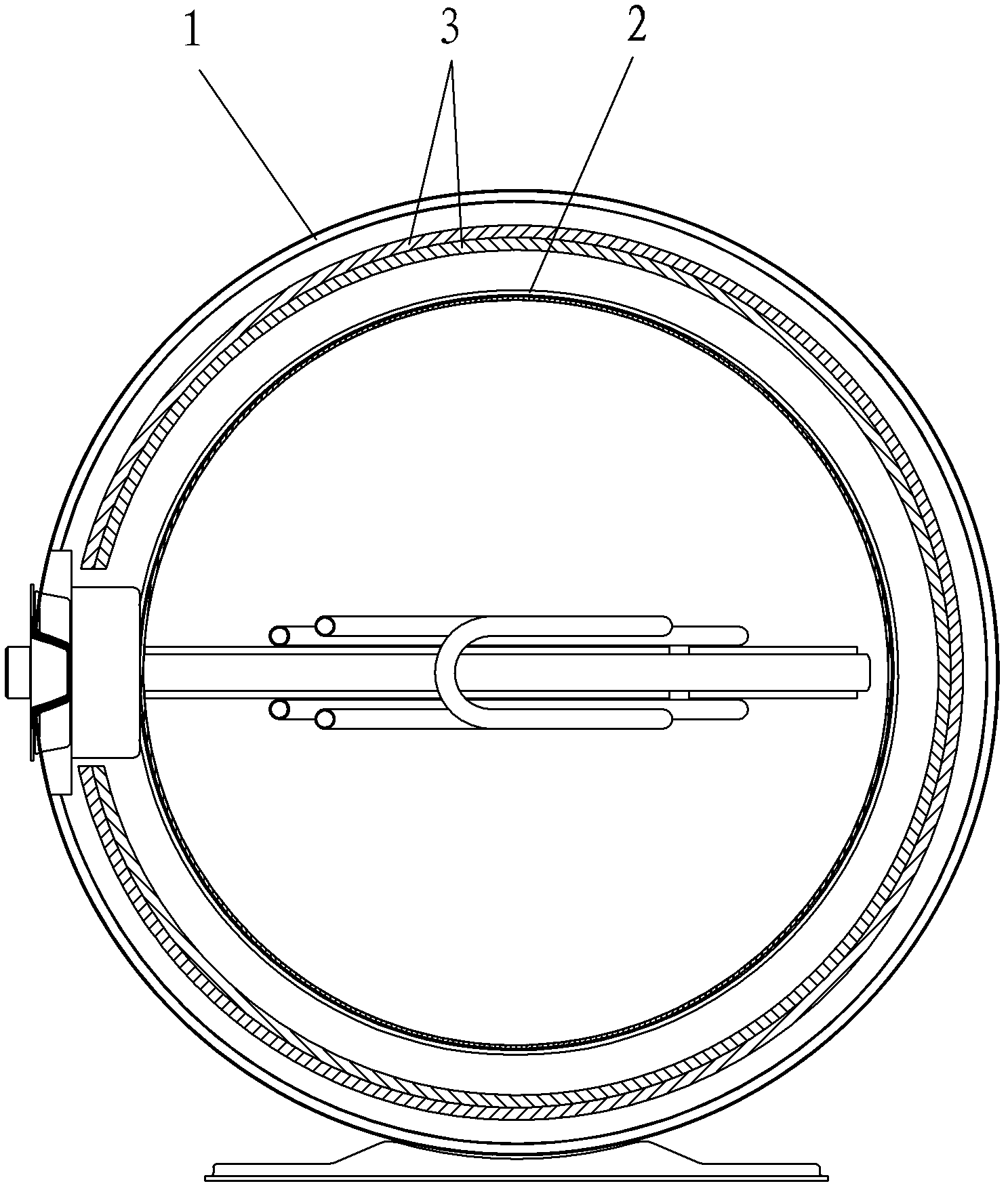

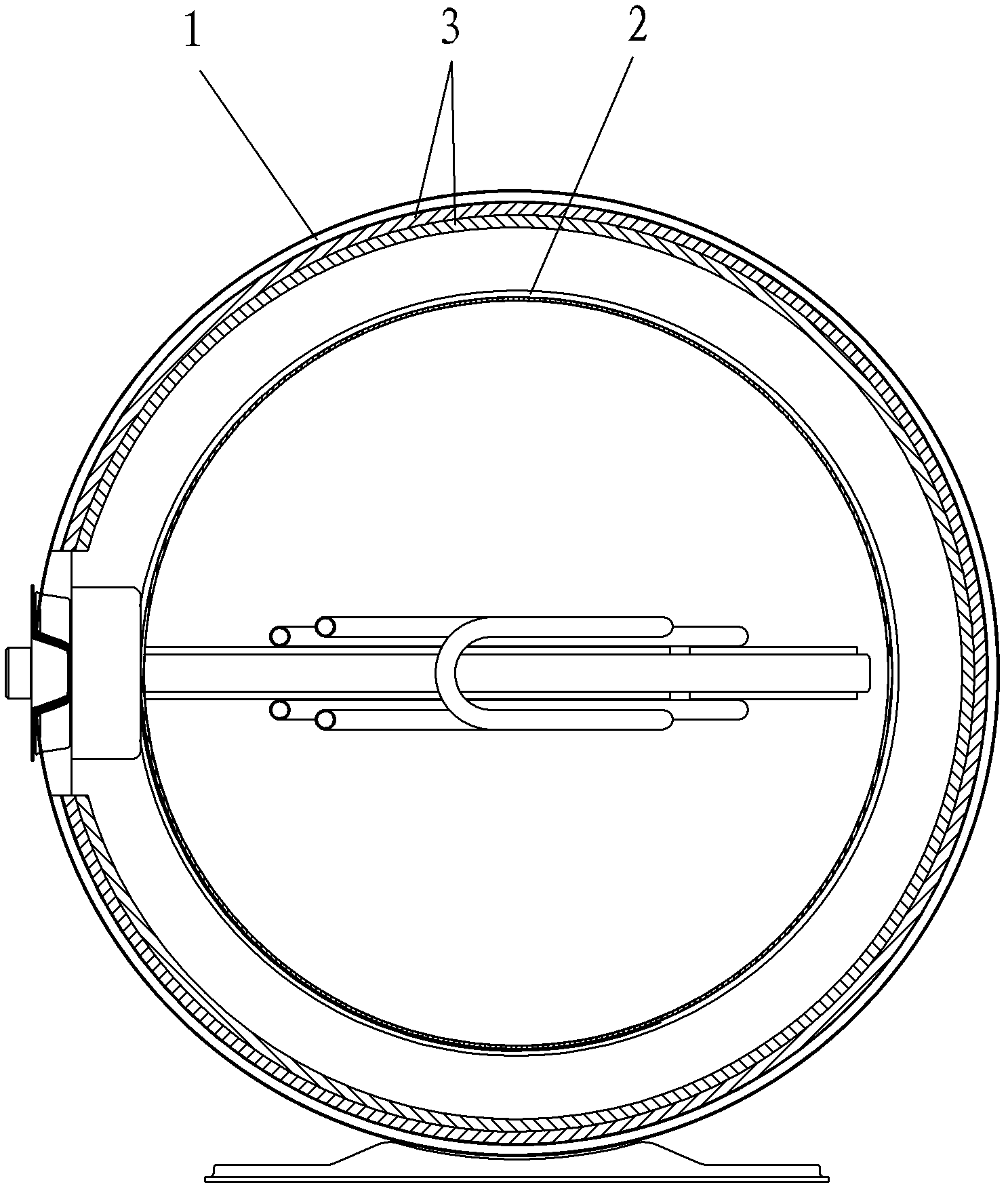

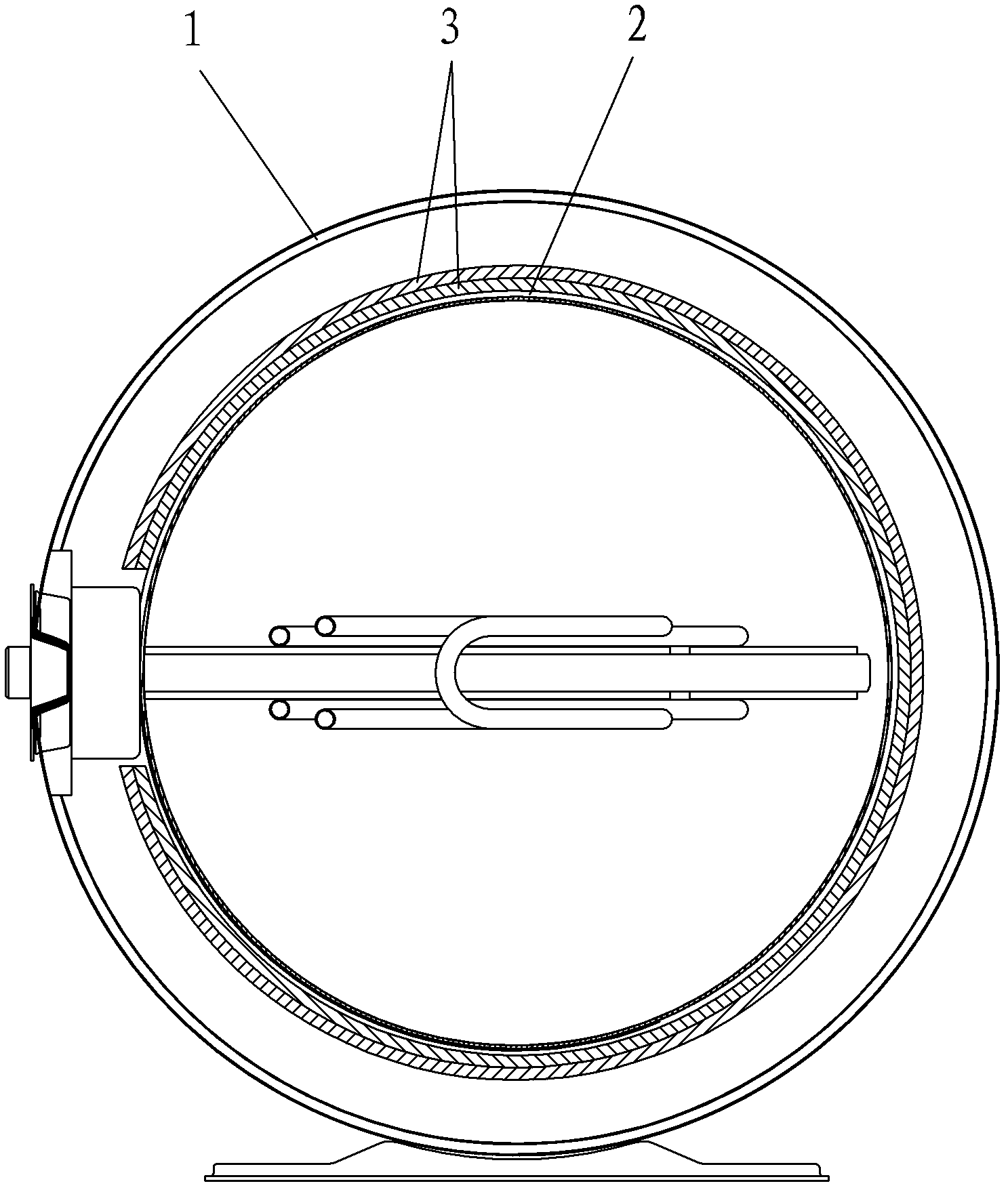

[0020] Such as Figure 1-3 Shown is a water heater using vacuum insulation panels for thermal insulation according to the present invention, which includes an outer shell 1, an inner tank 2 and a vacuum insulation layer (consisting of the following two vacuum insulation panels 3); the vacuum insulation layer is in the form of a ring Cylindrical, it is located between the shell 1 and the inner tank 2, specifically as figure 1 As shown, it is arranged between the shell 1 and the inner tank 2 and is separated from the two, or as figure 2 As shown, close to the inner wall of the shell 1, or as image 3 As shown, it is close to the outer wall of the inner tank 2; in addition, as Figure 1-3 As shown, the gap between the shell 1 and the inner tank 2 that is not filled by the vacuum insulation layer is also filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com