Steel ball drop test machine

A drop test and testing machine technology, used in impact testing, machine/structural component testing, measuring devices, etc., can solve the problems of deviation from the falling track, time-consuming and laborious impact stroke, and inability to choose the force point arbitrarily, so as to prevent power failure. or the effect of sudden breathlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical scheme of the present invention will be further described below in conjunction with the drawings.

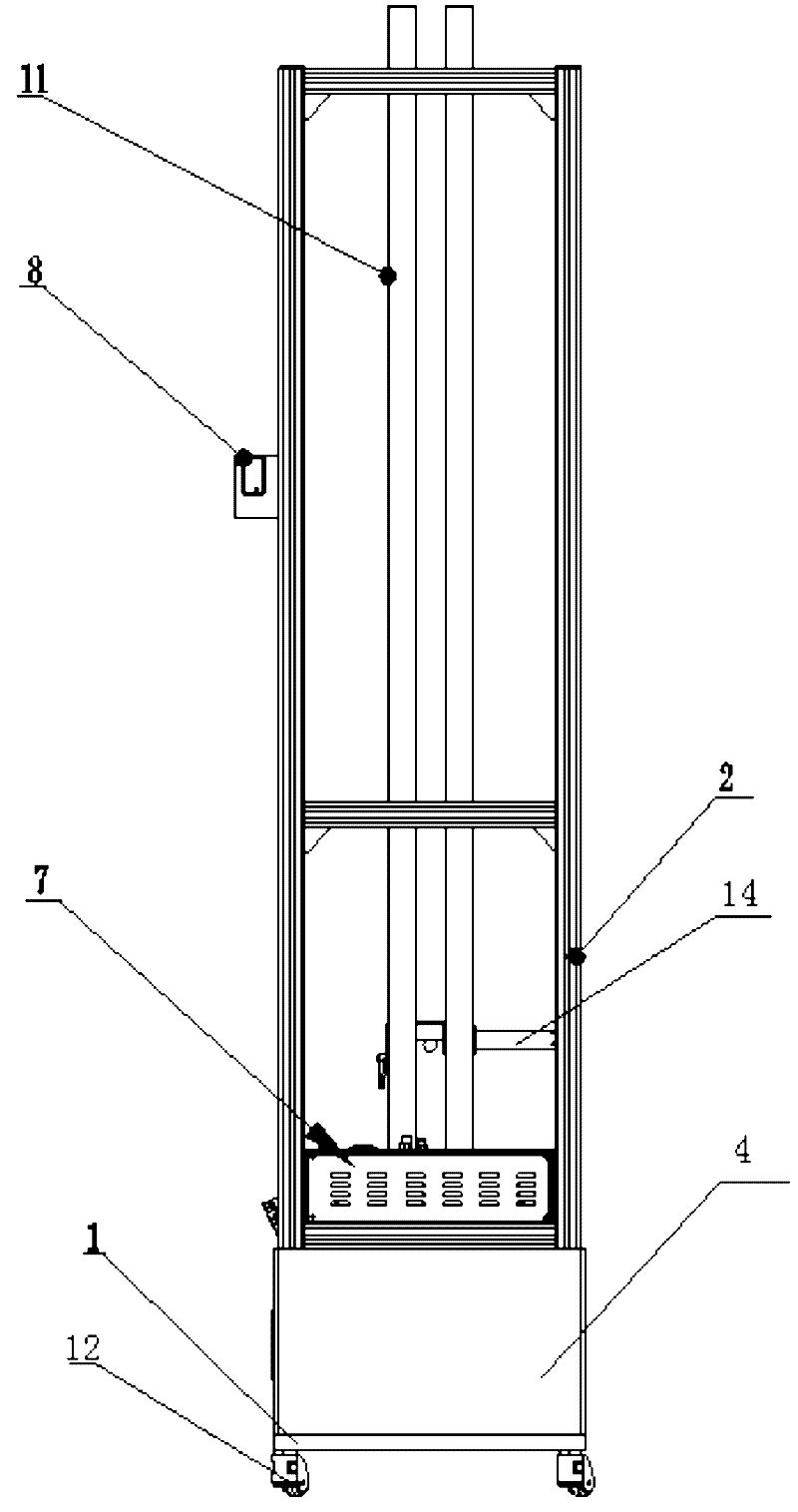

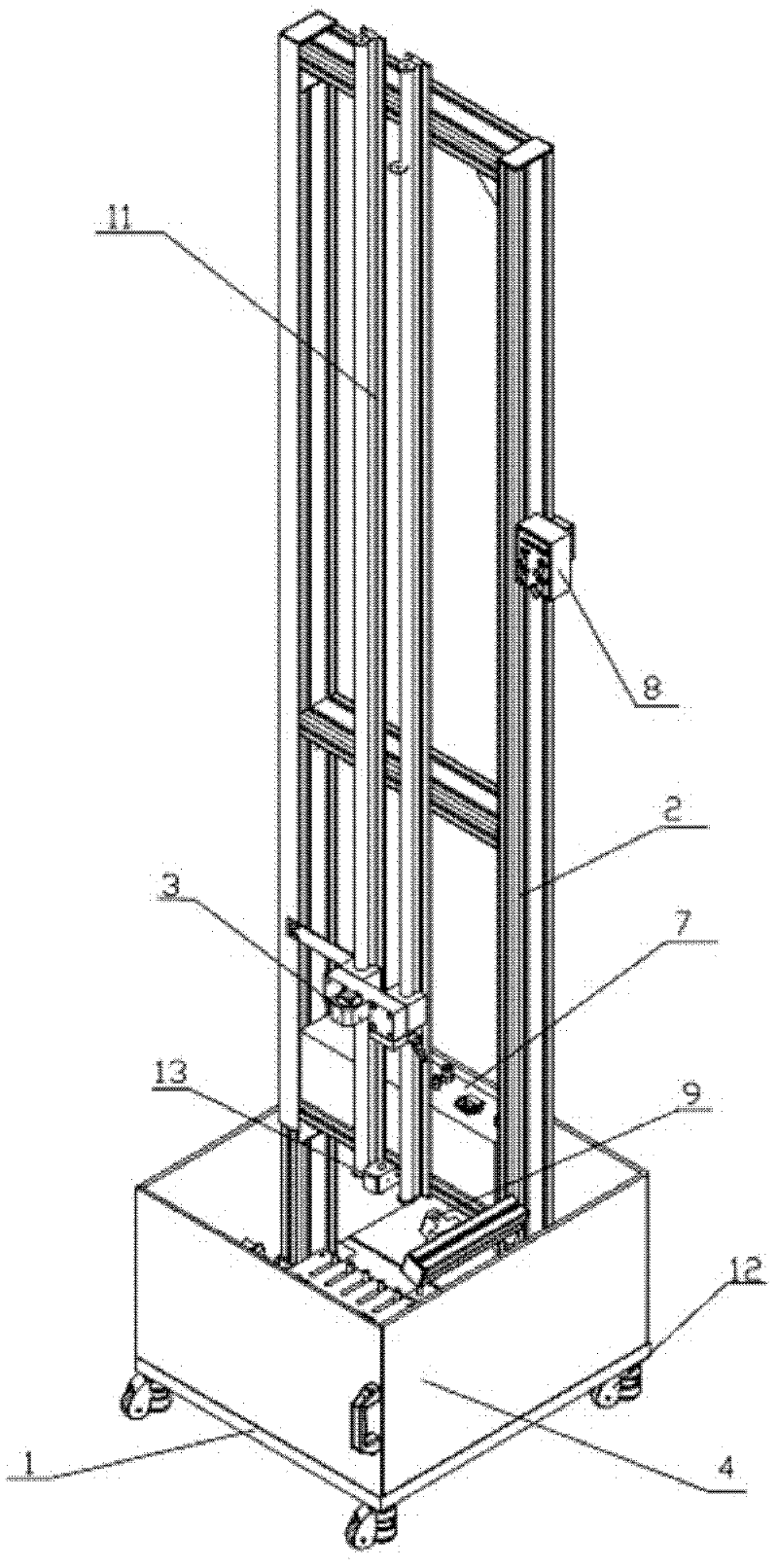

[0042] Such as Figure 1-9 As shown, a steel ball drop test machine of the present invention includes a bottom plate 1, a bracket 2, a steel ball adsorption assembly 3, a fence 4, a clamp assembly 5, a shielding assembly 6, an electrical box 7, and an operation box 8. The first laser light 9, the photoelectric sensor 10, the guide rail 11, the walking wheel 12 and the second laser light 13;

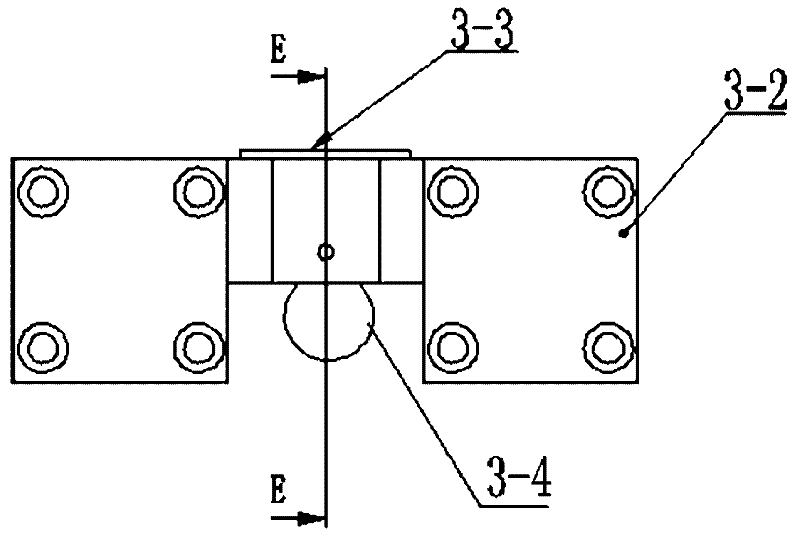

[0043] Among them, the steel ball adsorption assembly 3 includes a first electromagnet 3-1, an electromagnet seat 3-2, an electromagnet cover 3-3 and a steel ball 3-4;

[0044] The fixture assembly 5 includes a fixture base 5-1, a fixture housing 5-2, a mobile phone clamping column 5-3, a lead screw 5-4, a hand wheel 5-5, a tightening hand wheel 5-6, and a longitudinal sliding knob 5-7 , Horizontal sliding knob 5-8, tightening screw 5-9, guide shaft 5-10, lifting ramp 5-11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com