End screen differential digital output transformer

A digital output, transformer technology, applied in the direction of inductors, transformers/inductor coils/windings/connections, transformers, etc., can solve the problem that the capacitance of the low-voltage arm C2 of the output voltage of the capacitor voltage divider is not large enough, insulation failure faults, capacitance The problem of high output voltage of the voltage divider can achieve the effect of isolating primary equipment and measurement and control equipment, protecting measuring and measuring instruments, and ensuring the accuracy of current conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

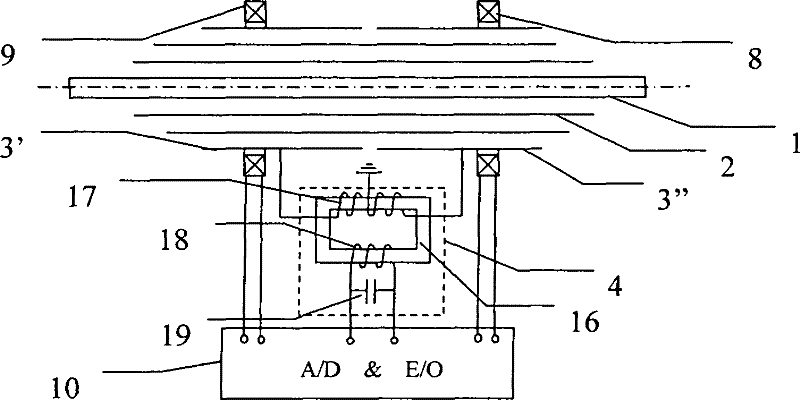

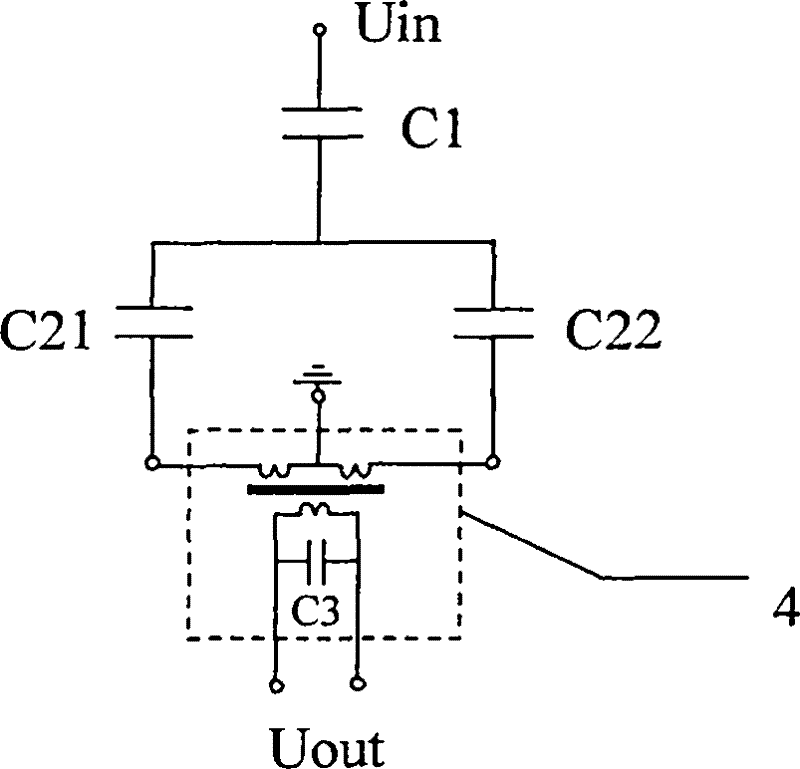

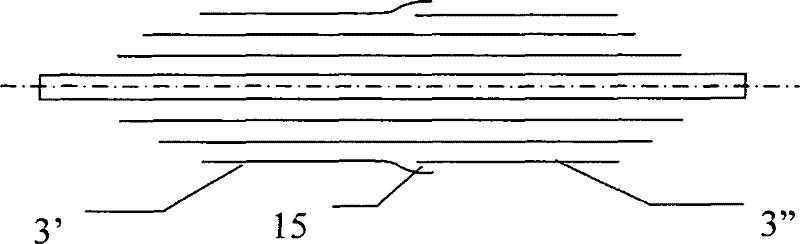

[0028] see figure 1 , the final screen differential digital output transformer of the present invention includes a high-voltage electrode (0 screen) 1, an intermediate capacitive screen 2, a final screen 3' and 3 "divided into two sections, a differential converter 4, an ultramicrocrystalline iron core coil 8, and silicon steel Sheet iron core coil 9, and integrated terminal 10. High-voltage electrode 1 is wrapped with insulating material, and intermediate capacitive screen 2 is laid at an appropriate position during the winding process. There can be multiple intermediate capacitive screens 2; the last capacitive screen (ie, the last screen) Divide it into two sections of 3' and 3" with different lengths, and tie the lead wires on 3' and 3" respectively, so that the capacitive primary winding of the final screen differential is completed. After laying two sections of the final screen 3' and 3", attention should be paid to the insulation between them, a feasible solution such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com