High efficient microwave energy receiving board formed by secondary wavelength resonance structural units

A resonant structure and energy receiving technology, which is applied in the direction of electrical components, electromagnetic wave systems, circuit devices, etc., can solve the problems of lower energy utilization rate and low energy conversion efficiency, and achieve the effect of variable structure, simple design structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

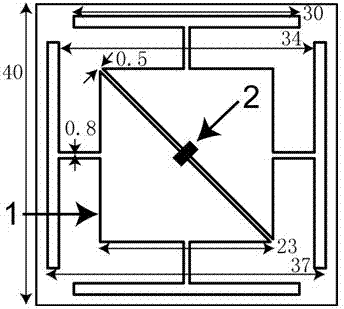

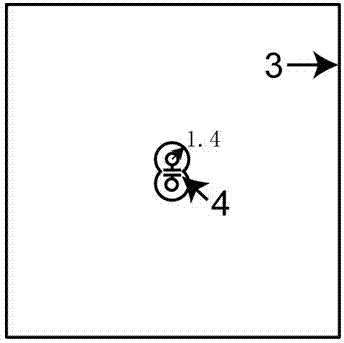

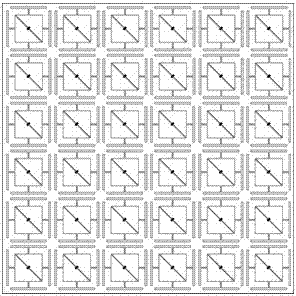

[0023] Such as figure 1 , figure 2 As shown, each sub-wavelength resonant unit is composed of three layers and has a square structure. A layer of square metal copper sheet 1 is plated in the middle of the Rogers circuit board on the middle layer. The square metal copper sheet 1 is composed of two isosceles right triangles. Both sides of the two isosceles right-angled triangle gaps are respectively connected to the two input interfaces of the high-frequency rectification chip 2, and as the input end of the high-frequency rectification circuit, the four sides of the square metal copper sheet 1 are respectively connected to the respective The strip-shaped metal copper sheet is connected, and each strip-shaped metal copper sheet is parallel to the four sides of the square respectively, and a layer of metal copper sheet bottom plate 3 is plated un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com