Optical fiber, in particular a laser fiber containing a doped glass fiber core and cladding around the fiberglass core

A technology of optical fiber and glass fiber, applied in the direction of multi-layer core/cladding optical fiber, cladding optical fiber, light guide, etc., can solve the problems of high mechanical stress, prefabricated core or fiber core cracking, etc., and achieve improved core or cladding The effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

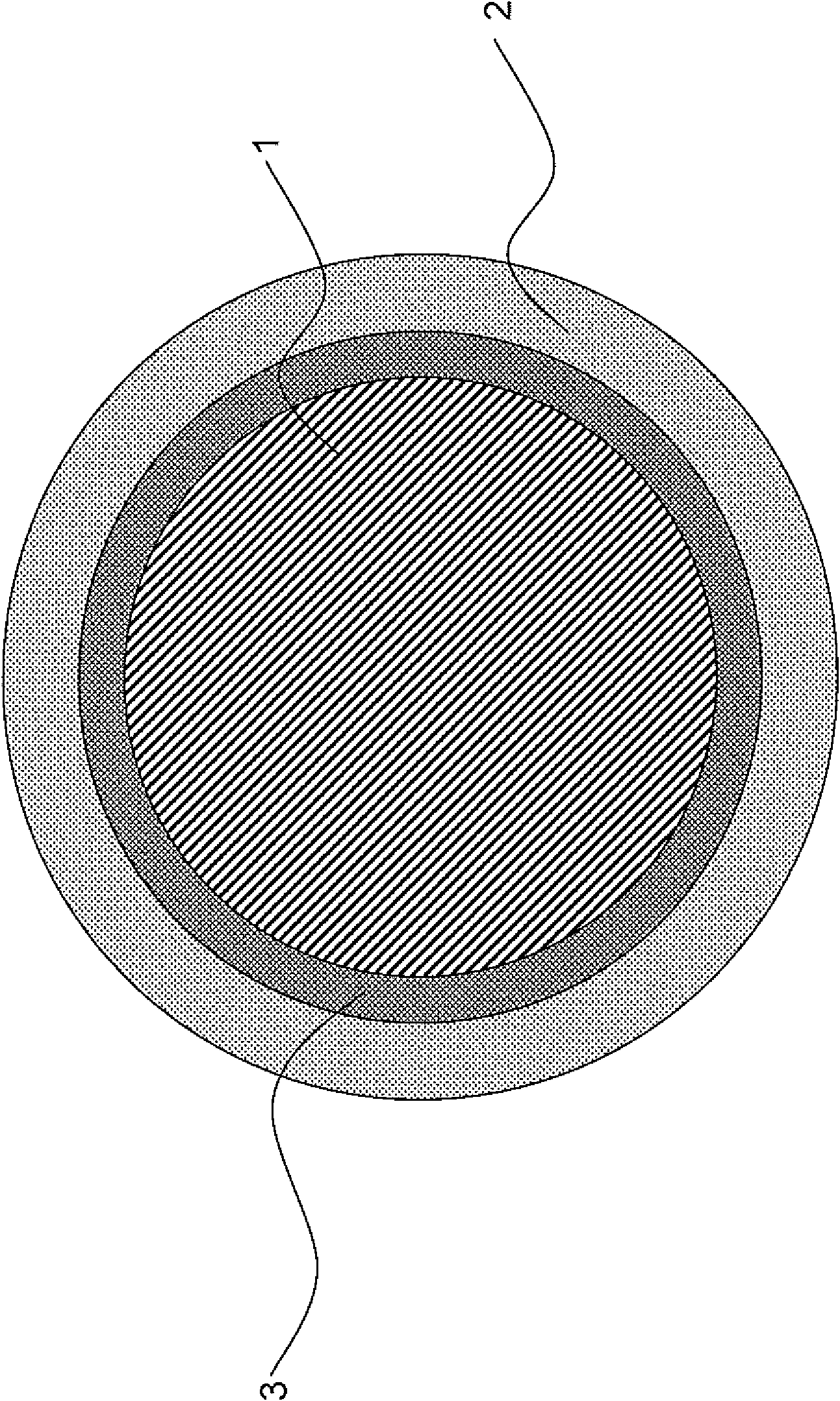

[0047] image 3 A cross-sectional view of an optical fiber body formed as a laser conductor is shown, comprising a glass fiber core 1 , a cladding 2 surrounding the glass fiber core and an intermediate layer 3 arranged between the glass fiber core and the cladding. The thickness of the cladding is greatly reduced in this example for reasons of clarity of illustration. In a practical optical fiber or laser fiber, the cladding has a thickness which is at least approximately equal to the size of the radius of the glass fiber core. The optical density and thus the refractive index decrease from the glass fiber core towards the cladding.

[0048] The intermediate layer is expediently doped in such a way that in the transition region formed by the intermediate layer between the relatively highly doped core and the undoped cladding region, there is no abrupt but stepwise shape transfer and at the same time reduce the mechanical stress occurring between the core and the cladding. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com