Stair strip sheet material with settled corners, method for manufacturing stair strip sheet material, and processing mold of stair strip sheet material

A technology for processing molds and stair strips, which is applied to the field of stair strips with subsidence at the corners and its manufacturing and processing moulds. It can solve the problems of complex pressing process, single variety of flame-retardant boards, and long time consumption, so as to achieve beautiful appearance and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (Example 1, the stair strip plate with corner settlement)

[0067] See Figure 9 , the stair strip plate material with corner settlement in this embodiment includes a base plate 7 and a veneer paper layer 6 pressed and fixed on the base plate 7. The base plate 7 is an integral component, which is parallel to each other in the front and rear directions and vertically arranged along the left and right directions All cross-sections have the same shape. The overlay paper layer 6 includes an impregnated paper layer 61 and a wear-resistant paper layer 62 .

[0068]The substrate 7 is composed of a head 71, a main body 72 and an extension 73 connected in sequence from left to right, and the head 71 is composed of a round head 71-1 and a connecting part 71-2 connected left and right. The outer peripheral side of the round head 71-1 is an arc-shaped curved surface that protrudes to the left, and the shape of the cross-section vertically arranged along the left and right directi...

Embodiment 2

[0073] (Example 2, the processing mold and preparation method of the stair strip plate with corner settlement)

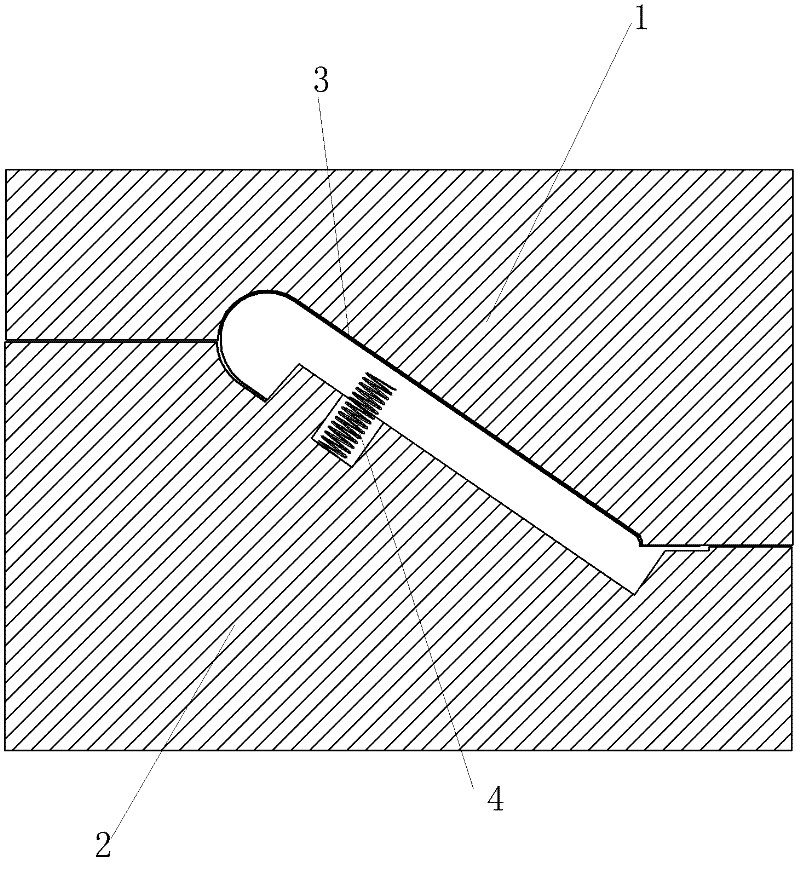

[0074] See figure 1 , The processing mold of the stair bar plate in this embodiment includes an upper mold 1 , a lower mold 2 , a spring pressing sheet mold 3 and an elastic member 4 . Both the upper mold 1 and the lower mold 2 are made of No. 45 mold steel, and the lengths of the upper mold 1 and the lower mold 2 are both 2500mm. In this embodiment, the elastic member 4 is a cylindrical compression spring.

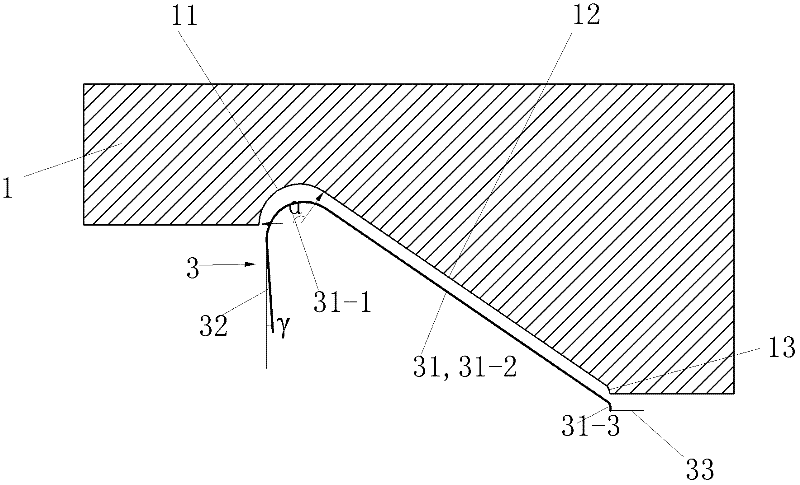

[0075] See figure 2 , the upper mold 1 is provided with a mold cavity with an opening towards the lower left, the surface of the mold cavity is a polished surface, and the surface of the mold cavity consists of a first arc surface 11, a first plane 12 and a second arc The shape surface 13 is connected successively from the upper left to the lower right and forms a smooth transition, and the shape of each section of the surface of the mold cavity in the fron...

Embodiment 3

[0110] (Example 3, the processing mold and preparation method of the stair strip plate with corner settlement)

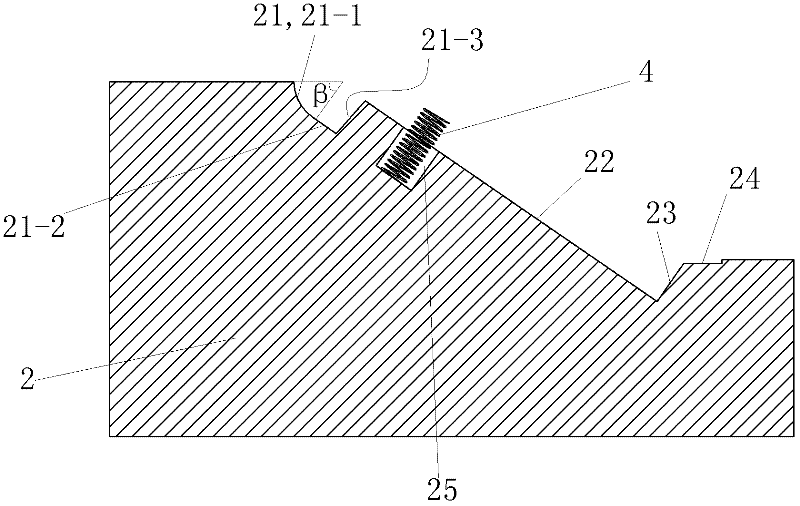

[0111] See Figure 11 , the remaining part of the processing mold of the stair bar plate of the present embodiment is the same as that of Embodiment 1, the difference is that: the depth of the installation groove 25 of the lower mold 2 is relatively shallow, and the installation groove 25 is arranged sequentially on a straight line along the front and rear Cuboid blind hole. The elastic component 4 disposed in the installation groove 25 is a leaf spring, and the depth of the installation groove 25 is greater than the thickness of the leaf spring 4 . The lower end of the leaf spring 4 is fixed on the lower end of the installation groove 25 by welding or riveting, and the upper end of the leaf spring 4 is located outside the third plane 22 when no external force is applied, and can be pressed below the third plane 22 when subjected to an external force.

[0112] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com