Multifunctional plastic repair machine

A multi-functional, plastic technology, applied in the field of plastic repairing machines, can solve the problems of inconvenient portability, inconvenience of the same power supply, and inconvenience in work between the nail planting machine and the heating and troweling tool, and achieves a portable, easy-to-use, and simple-to-use structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

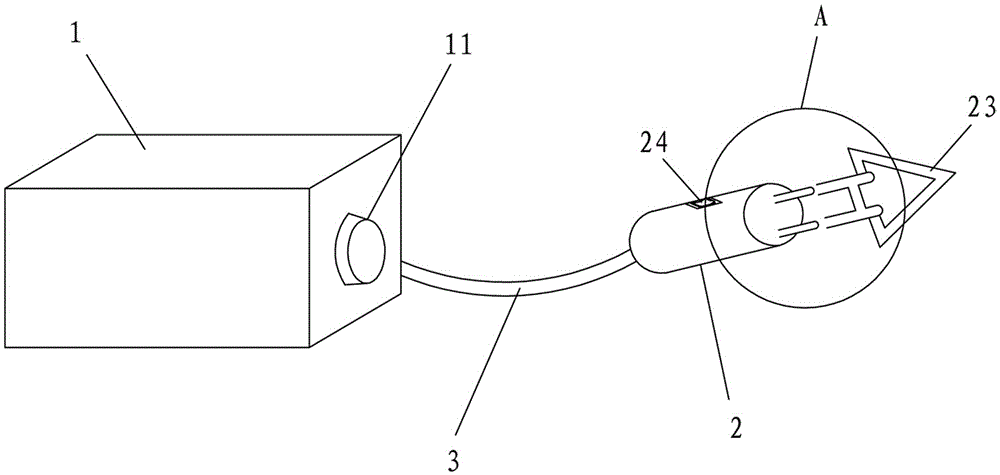

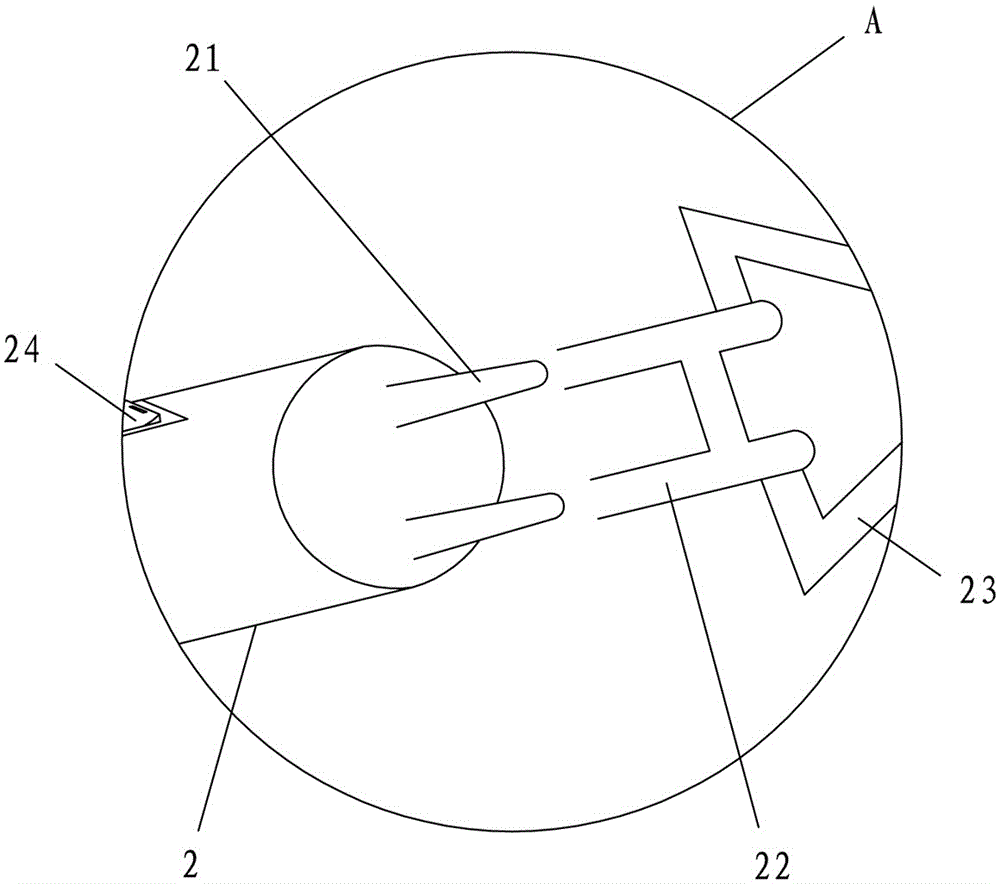

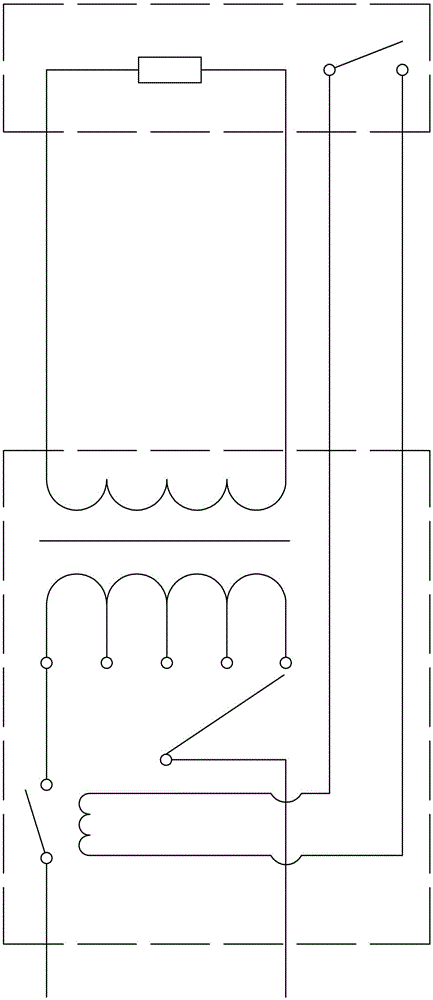

[0017] refer to Figure 1 to Figure 3 , a multifunctional plastic repairing machine of the present invention includes a power module 1 and an operating handle 2 for performing process operations. The power module 1 is a transformer with multiple current and voltage adjustment gears. The power module 1 is provided with an adjustment knob 11. The magnitude of the current delivered to the welding head 21 can be changed by turning the adjusting knob 11. The operating handle 2 is connected to the power module 1 by a wire 3, and the end of the operating handle 2 is provided with a welding device for energizing and heating. The welding head 21 is covered with a metal connecting sleeve 22. The upper part of the welding head 21 is thinner and the lower part is thick so that the metal connecting sleeve 22 is fastened on the welding head 21 when it is socketed. The metal connecting sleeve 22 The outer diameter is not less than 8mm. When the metal connecting sleeve 22 is sleeved on the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com