Automatic laminating machine

A laminating machine, automatic technology, applied in the direction of lamination device, control lamination, lamination, etc., can solve the problems of difficult processing efficiency, injury to operators, poor uniformity of flexible circuit boards, etc., to reduce the possibility of safety accidents , Improve processing efficiency, facilitate the effect of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

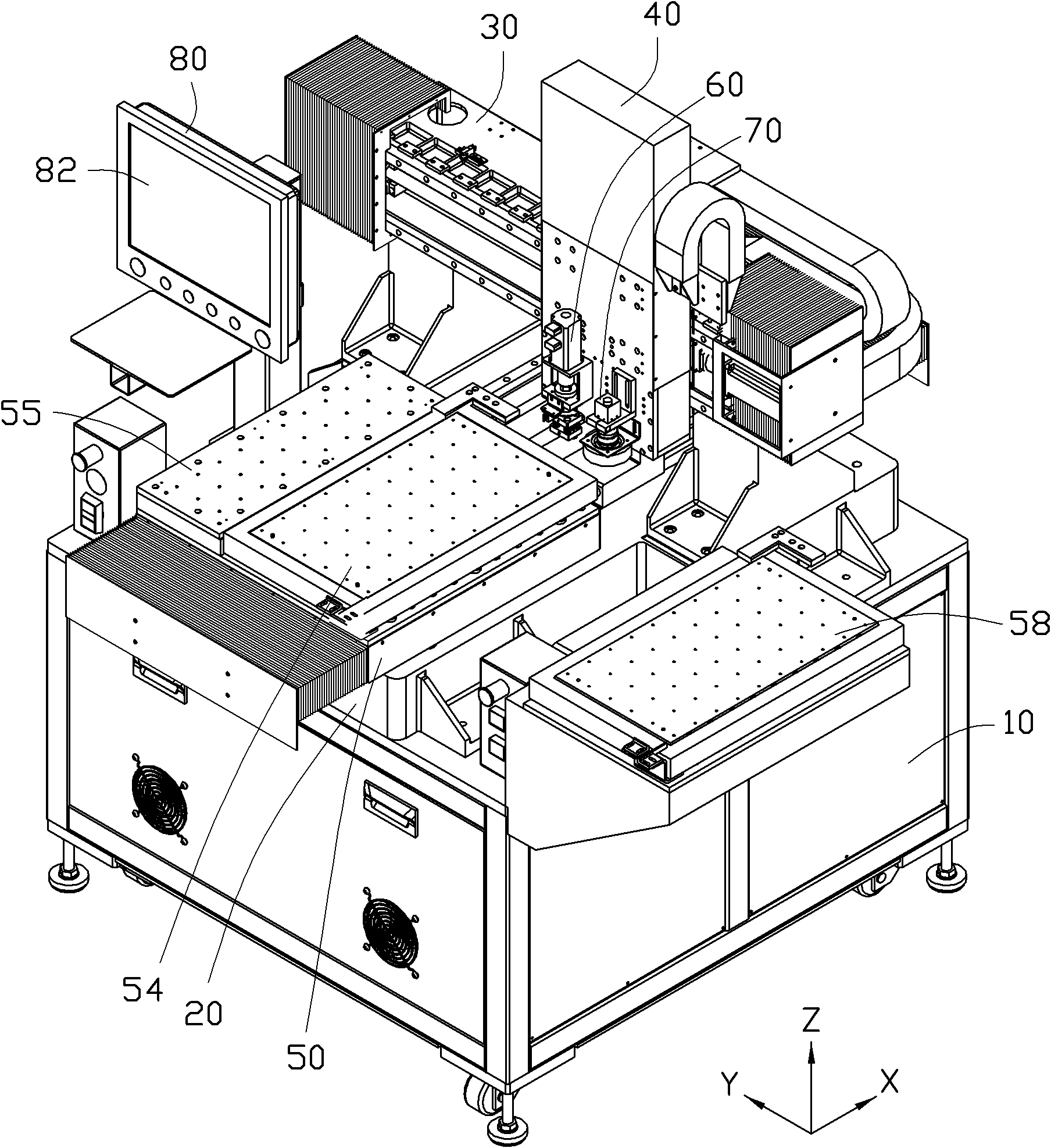

[0072] see figure 1 , an embodiment of the present invention provides an automatic laminating machine 100, which is used to attach accessories to products to be bonded. The automatic laminating machine 100 includes a frame 10, an X-axis moving mechanism 20, a Y Axis moving mechanism 30 , a Z-axis moving mechanism 40 , a worktable 50 , a sucking and pressing mechanism 60 , an image system 70 , and a control system 80 .

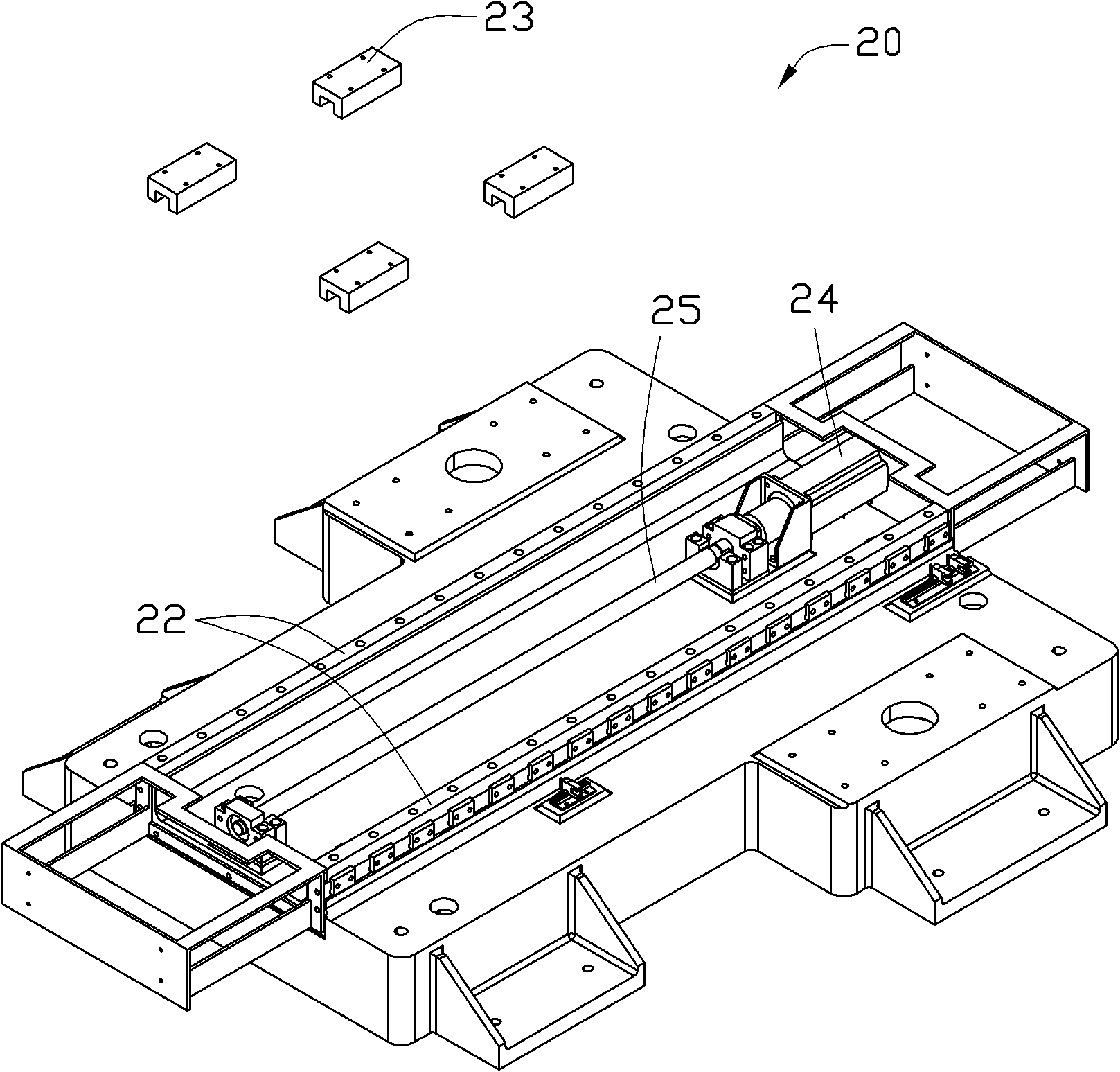

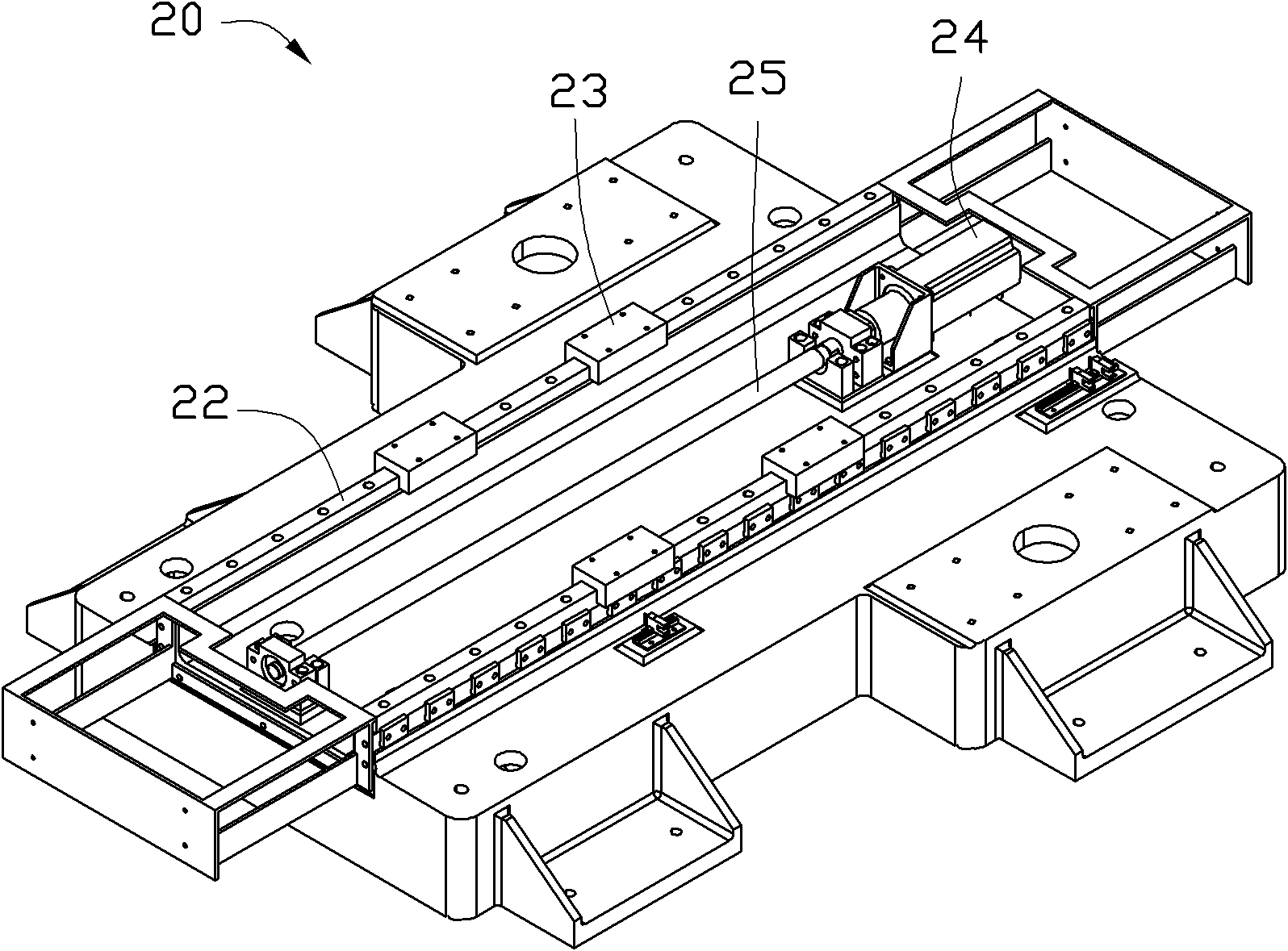

[0073] The frame 10 is the base body of the automatic laminating machine 100, and is used to carry and install the X-axis moving mechanism 20, the Y-axis moving mechanism 30, the Z-axis moving mechanism 40, the workbench 50, The suction pressing mechanism 60 and the imaging system 70 . The workbench 50 is used to carry accessories and products to be pressed. The X-axis moving mechanism 20 , the Y-axis moving mechanism 30 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com