Brake structure and wheelchair comprising same

A wheelchair and brake component technology, applied in the field of brake structure, can solve problems such as accidents, easy rushing down steep slopes, and very difficult problems, and achieve the effects of increasing safety and handling, preventing accidents, and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

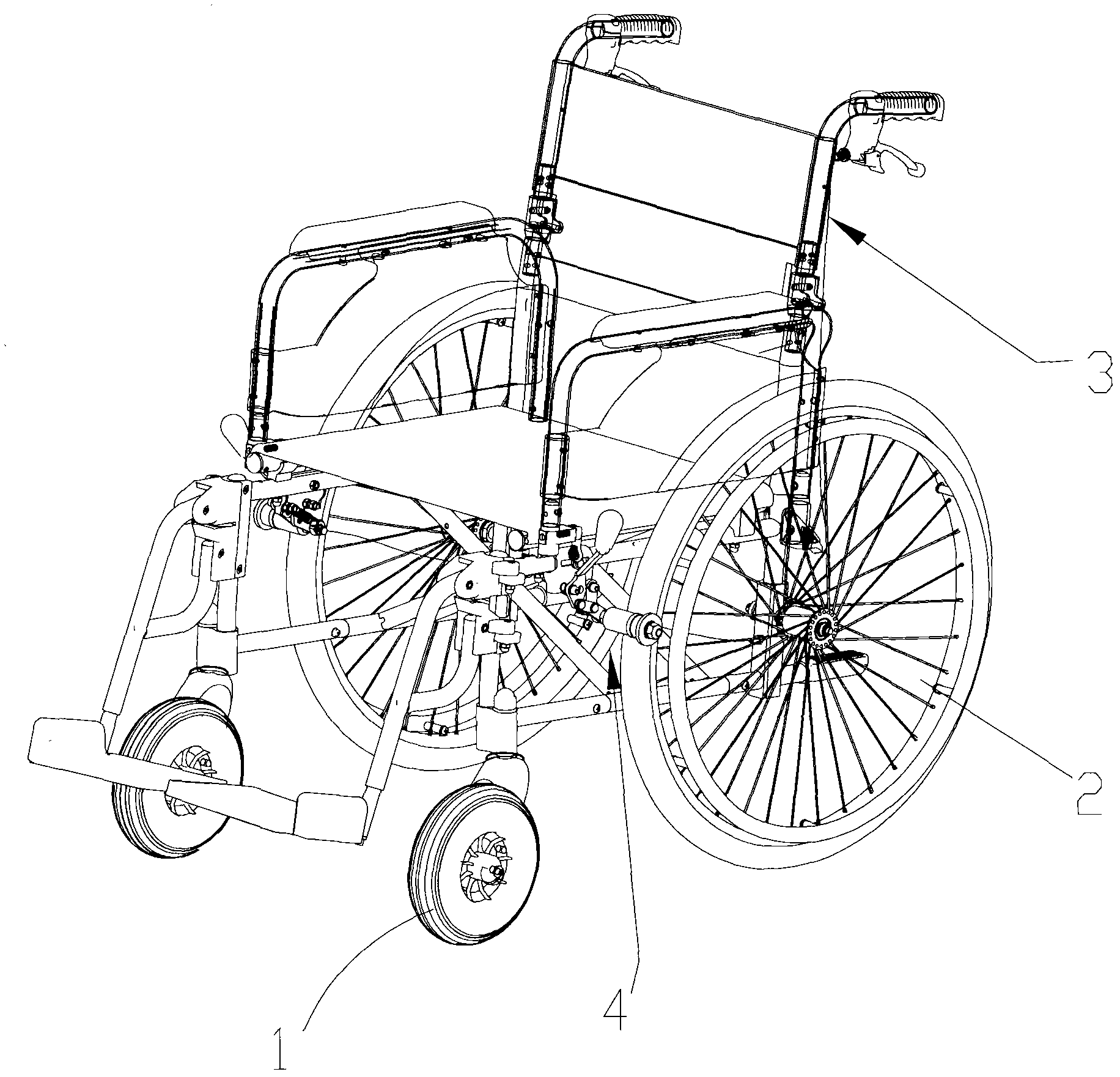

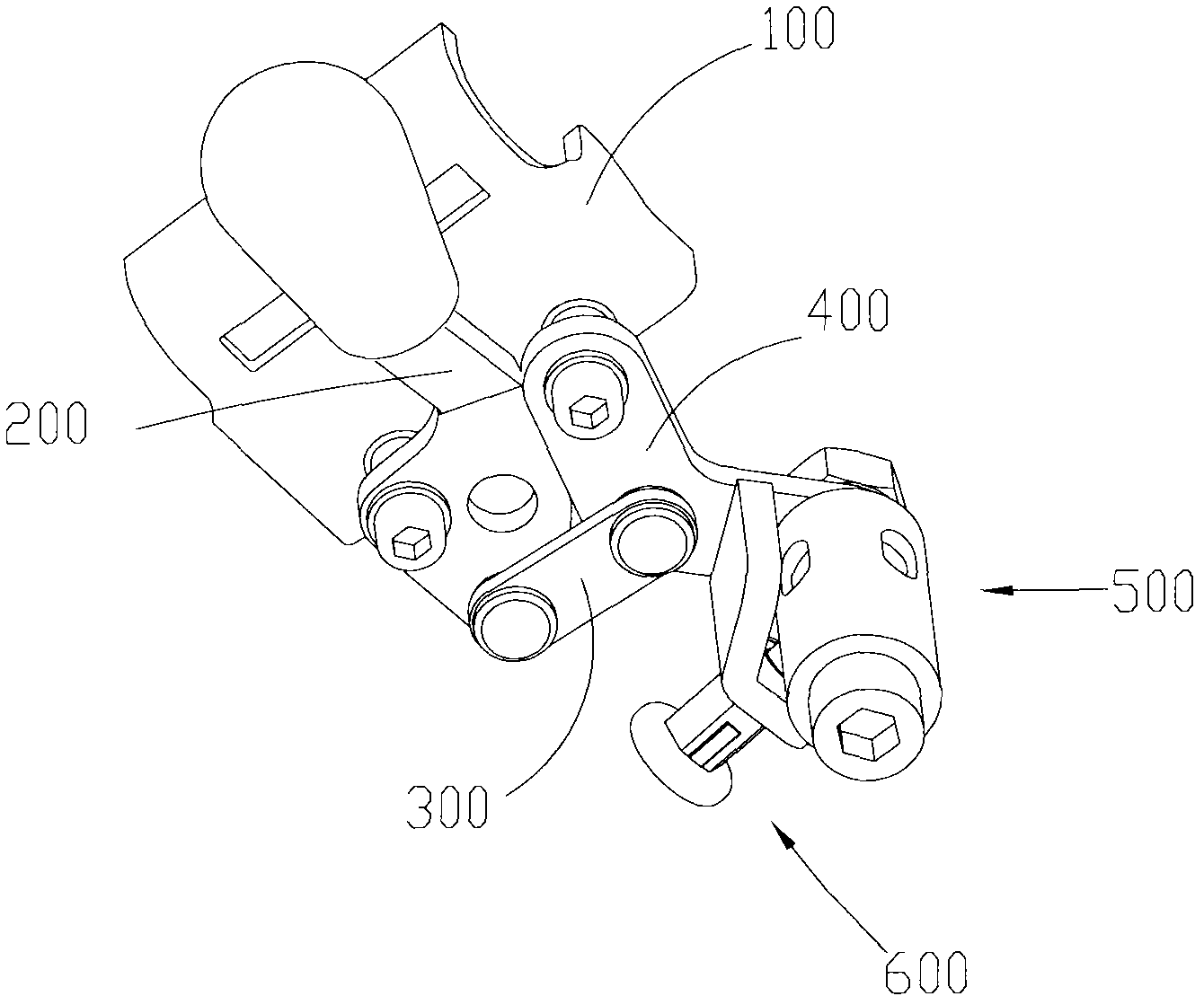

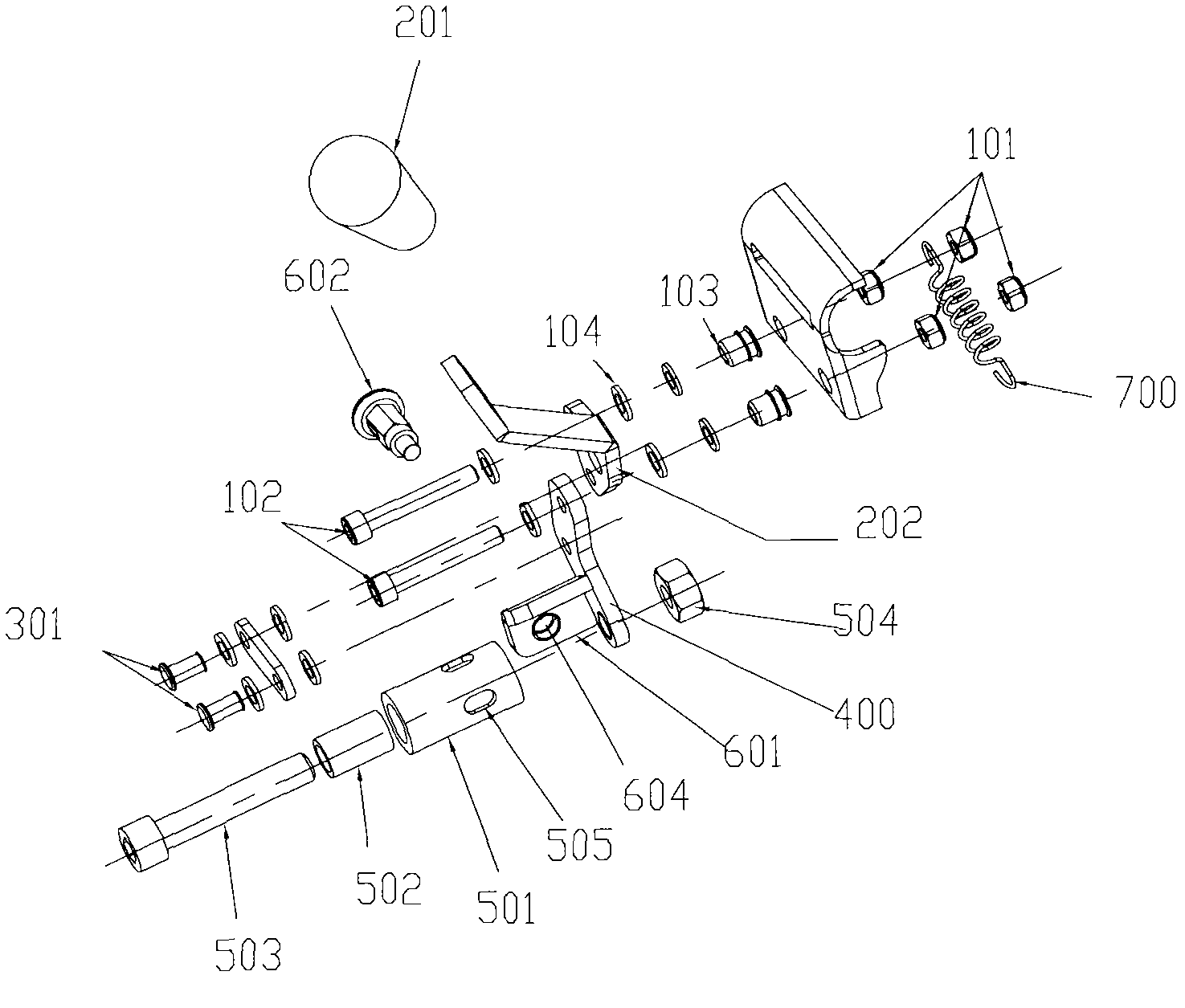

[0026] Embodiment 1: as figure 2 with image 3 As shown, the brake structure 4 mainly includes a mounting base plate 100 and a brake assembly 500 that is movably arranged on the mounting base plate 100 and is used to contact and rub the rear wheel of the wheelchair. The mounting base plate 100 is fixedly connected to the front part of the vehicle frame 3, And close to the rear wheel, so that the user can operate the brake. A handle 200 , a connecting rod 300 , a swing arm 400 , a locking mechanism 600 , a return spring 700 and the like are rotatably connected to the installation base 100 . The handle 200 includes a handle cover 201, a driving rod 202 and a mounting hole (not marked in the figure), etc., the handle 200 is connected to the mounting base plate 100 through a small screw rod 102 and a small nut 101 in rotation, and between the handle 200 and the mounting base plate 100 There is a spacer 104 and a sleeve member 103, the function of which is to make the handle 200...

Embodiment 2

[0030] Embodiment 2: The difference from Embodiment 1 lies in the locking mechanism 600. In Embodiment 2, the brake assembly 500 and the locking mechanism 600 are arranged along the axial direction. Its structure is as Figure 4 , 5 , 6, the brake assembly 500 is composed of a mandrel 503, a friction wheel 501, a one-way bearing 502, a mandrel nut 504 and the like. A locking plate 601 with a larger outer diameter is welded on the mandrel 503. There are two symmetrical locking plate sockets 604 on the locking plate 601. The socket 505 on the friction wheel 501 is arranged on its axial end surface. The friction wheel 501 and The one-way bearing 502 is mounted on one end of the mandrel 503 and fixed axially by the mandrel nut 504 . The locking mechanism 600 is composed of a locking plate 601, a locking part 602, and a clutch end cover 603. The clutch end cover 603 has a hole corresponding to the jack 604, and the two locking parts 602 are interference fit in the hole of the clu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com