Glass storage and transport device

A mobile device and glass technology, applied in the direction of transportation and packaging, packaging of vulnerable items, types of packaged items, etc., can solve problems such as mutual pollution, achieve the effects of avoiding mutual pollution, improving mass production of glass, and saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

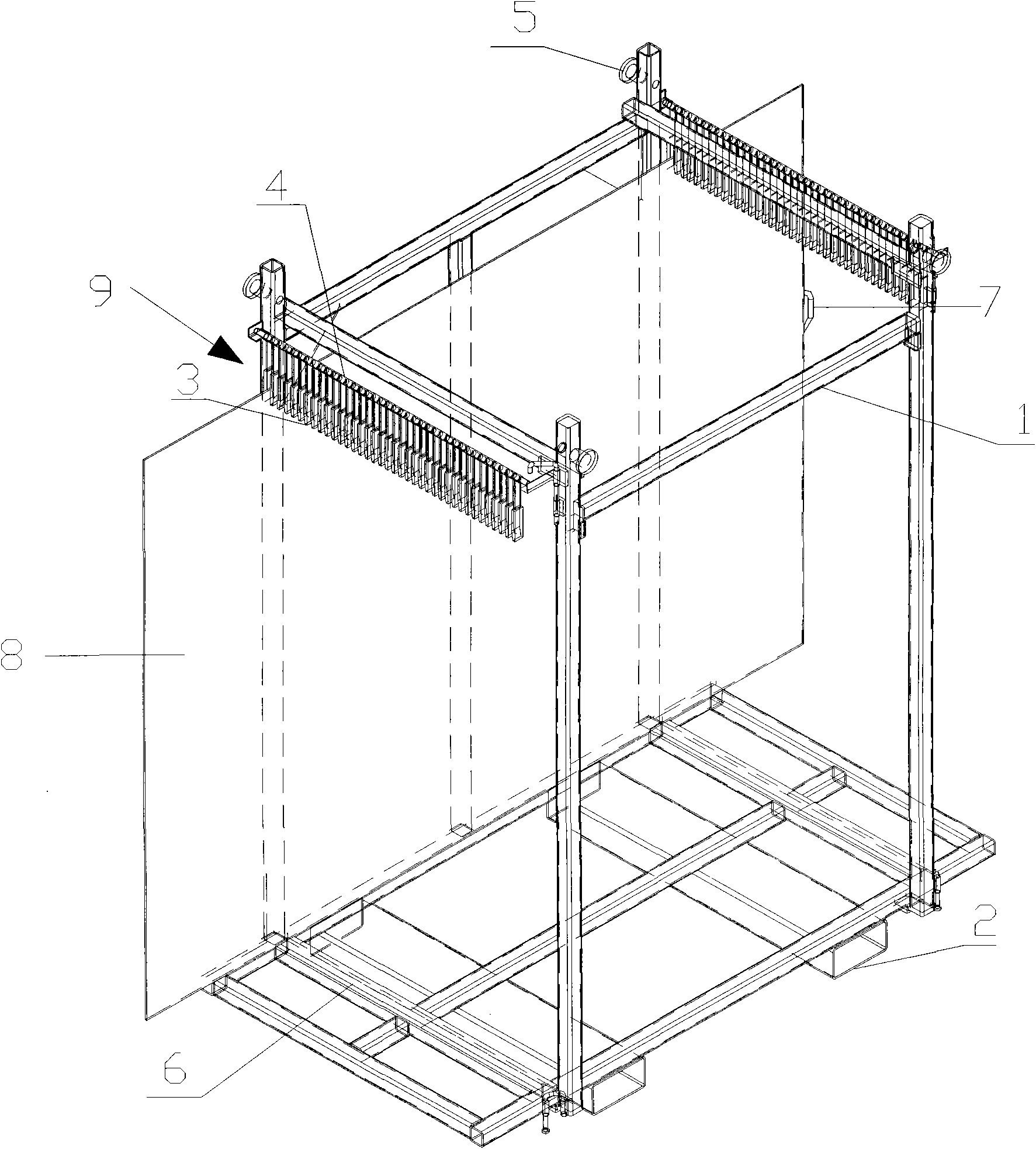

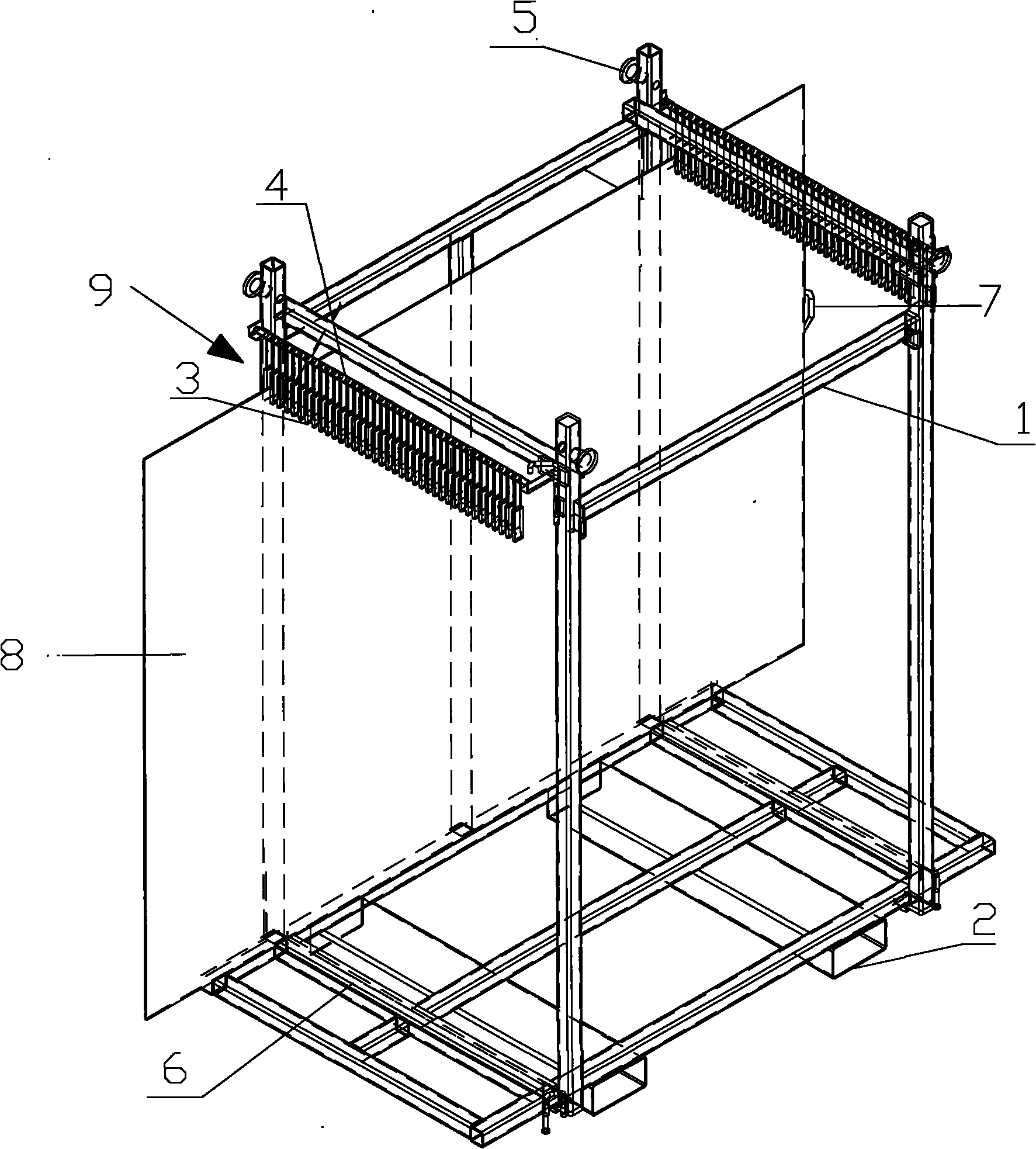

[0019] like figure 1 As shown, a glass storage and moving device includes a bracket 1 , a pair of forklift limit slots 2 , four hooks 5 , a rubber backing plate 6 , a handrail 7 , and a pair of limit mechanisms 9 . The support 1 is a cube made of 4 longitudinal beams and many cross beams. The bottom of the bracket 1 is provided with a pair of forklift limiting slots 2, which can facilitate the insertion of a forklift and move the device. The upper ends of the 4 longitudinal beams of the device are respectively provided with a suspension hook 5 for tying steel wire ropes, and the device can be hoisted afterwards. A pair of limiting mechanisms 9 are respectively arranged on the upper parts of the two opposite sides of the bracket 1 . The limit mechanism 9 includes 38 limit blocks 3 and limit block fixing rods 4 . The limit block 3 is connected to the limit block fixing rod 4 according to the thickness of the glass to form a limit groove for separating the glass 8 and preventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com