Method for degrading organophosphorus pesticide based on sweep-frequency double-frequency ultrasonic technology

An organophosphorus pesticide, ultrasonic technology, applied in chemical instruments and methods, mechanical oscillation water/sewage treatment, water pollutants, etc., can solve problems such as degrading harmful substances, and achieve the effect of energy saving and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

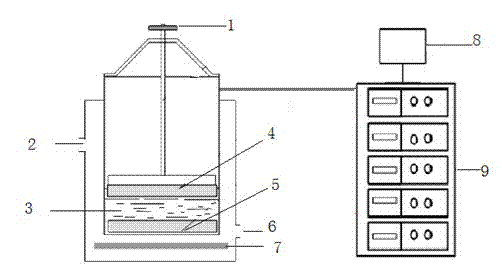

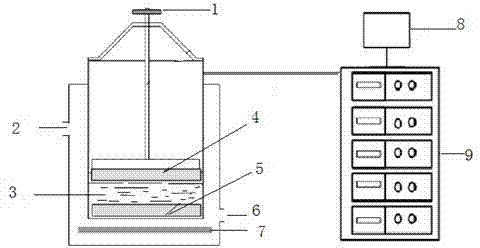

Image

Examples

Embodiment 1

[0022] Dimethoate solution with an initial concentration of 3 mg / L was prepared with 40% dimethoate EC. The temperature was set at 25 °C, the reactor volume was 4 L, and the dimethoate solution was ultrasonically treated under constant frequency conditions of 22 kHz, 28 kHz, 33 kHz, 40 kHz and 68 kHz. The optimal degradation frequency was 68 kHz, and the optimal degradation rate of dimethoate was 34.8 % after 180 min.

[0023] Table 1 The degradation rate of dimethoate pesticides at different frequencies (%)

[0024] 0 minutes 20 minutes 40 minutes 60 minutes 90 minutes 120 minutes 150 minutes 180 minutes 22 kHz 0 2.15 3.18 6.43 8.1 12.49 13.93 16.33 28 kHz 0 3.59 4.64 6.03 9.21 13.32 13.43 16.64 33 kHz 0 3.21 7.82 11.5 14.27 15.21 15.3 18.78 40 kHz 0 1.78 2.76 5.51 8.66 9.72 9.94 12.13 68 kHz 0 4.59 10.4 16.87 22.92 26.72 30.63 34.8

Embodiment 2

[0026] Different volumes of dimethoate pesticide solutions were treated with 68 kHz fixed-frequency ultrasonic waves, the pesticide concentration was 3 mg / L, and the treatment time was 180 min. It was concluded that the degradation rate was the highest when the treatment volume was 8 L, and the degradation rate was 49.02 %.

[0027] Table 2 The degradation rate (%) of dimethoate pesticide under different treatment volumes

[0028] Capacity (L) 4 6 8 10 12 14 Degradation rate(%) 36.51 48.61 49.02 37.05 34.35 33.74

Embodiment 3

[0030] 68 kHz ultrasonic wave was used as the degradation frequency, the initial concentration of dimethoate was 3 mg / L, and the treatment volume was 4 L. Investigate fixed frequency (frequency 68 kHz) and sweep frequency (periods are 100 ms, 300 ms, 500 ms, 700 ms and 900 ms respectively, and the frequency changes linearly between 66 kHz and 70 kHz), the two ultrasonic modes have great effect on music effect on fruit degradation. The degradation of dimethoate under all sweeping frequency conditions was better than that under the constant frequency condition, and the effect was the best when the sweeping frequency was 100 ms, and the degradation rate of dimethoate was 63.3% in 180 min.

[0031] Table 3 The degradation rate of dimethoate under different frequency sweep periods (%)

[0032] 0 minutes 45 minutes 90 minutes 135 minutes 180 minutes fixed frequency 0 8.96 15.77 20.56 26.78 100ms 0 25.86 44.77 54.99 63.24 300ms 0 27....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com