Fiberglass reinforced black acrylonitrile-butadiene-styrene modified plastic capable of heat resistance and impact resistance, and its preparation method

A glass fiber and styrene technology, applied in the field of modified plastic materials and their preparation, can solve the problems of low tensile strength, poor heat resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below by way of examples and comparative examples. Under the condition of not violating the purpose of the present invention, the present invention should not be limited to the specific express contents of the following experimental examples.

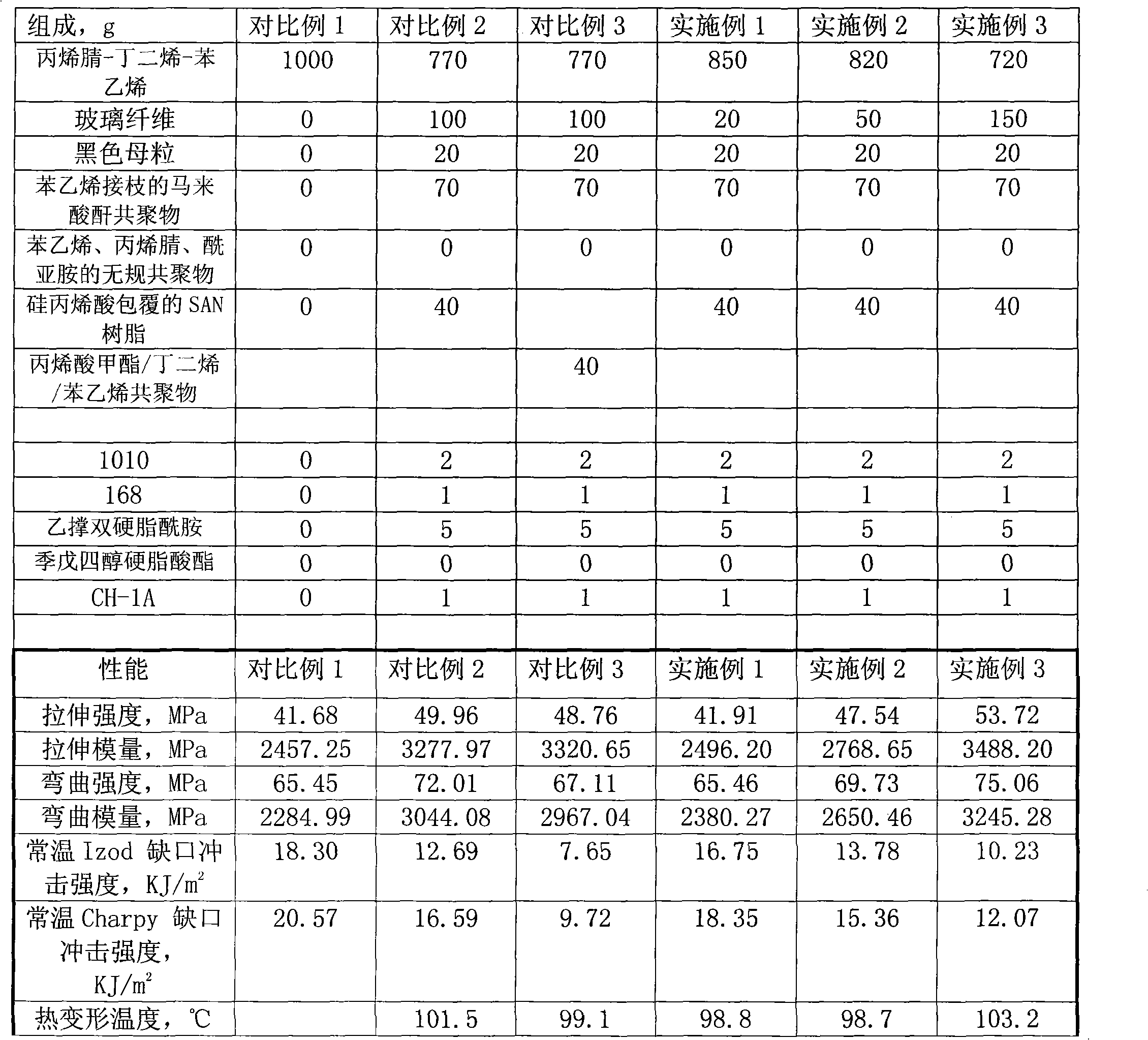

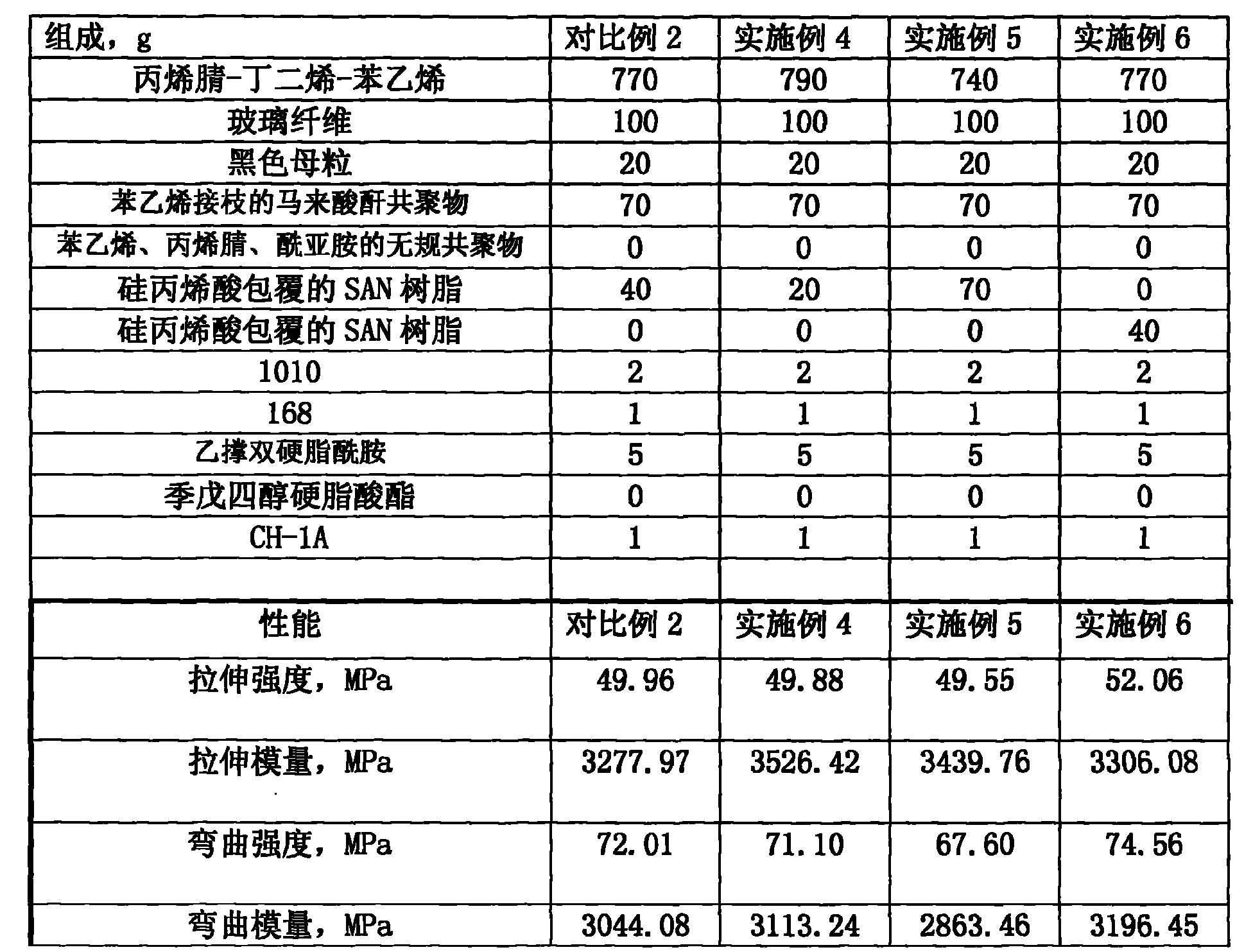

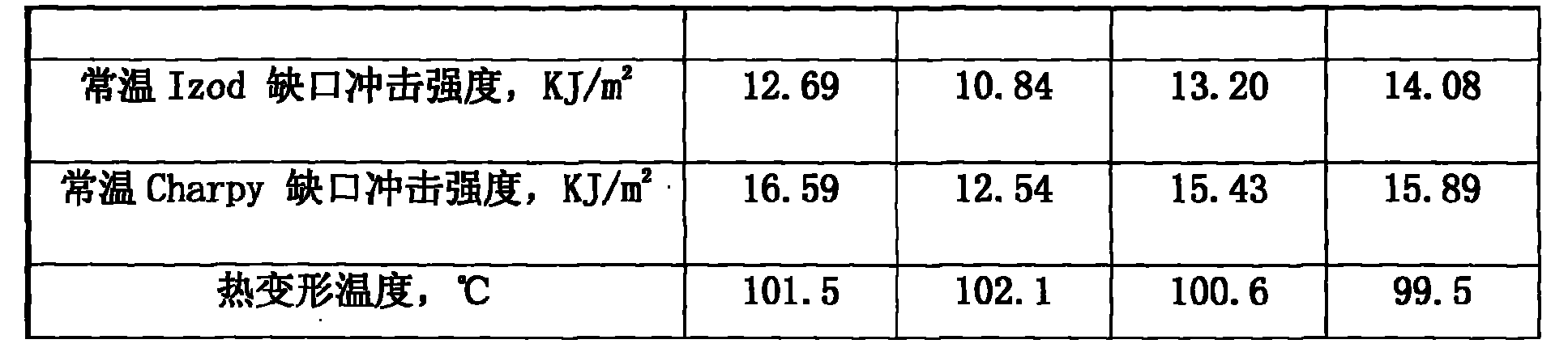

[0025] (1) Examples 1-3 and Comparative Example 2 are mainly to evaluate the influence of adding different amounts of glass fiber on the system. Example 1, Example 2, Comparative Example 2, and Example 3 have glass fiber ratios of 2%, 5%, 10%, and 15% of the main components (except processing aids and antioxidants) respectively. Comparative example 3 is to replace the impact modifier 1 with the impact modifier 2, the impact modifier 1 is a silicone acrylic anti-impact agent, and the impact modifier 2 is polymethyl methacrylate-butadiene -Styrene core-shell structure anti-impact agent. The weight of each raw material is shown in Table 1. After drying and mixing, enter the twin-scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com