Rapid junction box

A junction box and fast technology, applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of poor machining accuracy, difficult separation of conductive sheets, affecting the wiring effect, etc., to achieve convenient production, good wiring effect, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

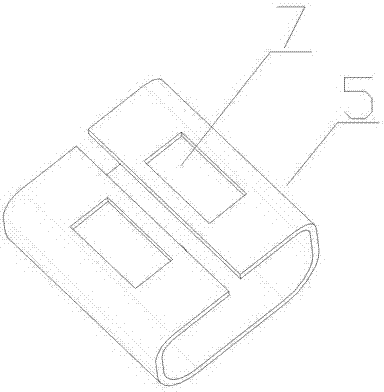

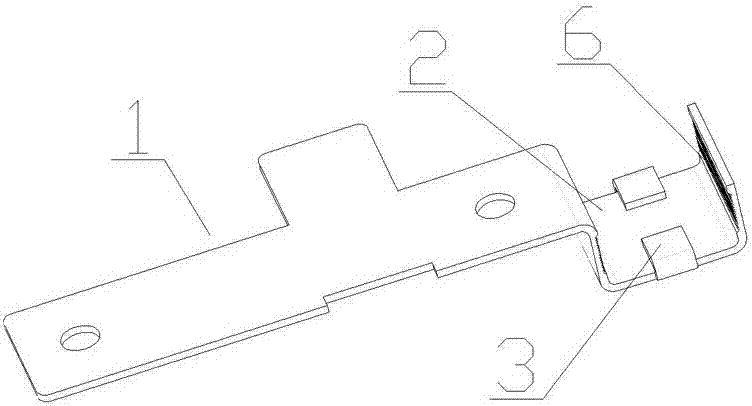

[0018] see figure 2 , The retaining spring 5 is "C" shaped with an upward opening, and a through hole 7 is respectively provided on both sides of the opening on the upper surface. see image 3 , the front end of the metal conductive sheet 1 has a storage hole 2, the size of which matches the circlip 5; the two sides of the bottom of the storage hole 2 each have a movable buckle 3 that can be opened and closed, and the opening and closing direction of the movable buckle 3 and the accommodation The opening direction of the side of the hole 2 is parallel;

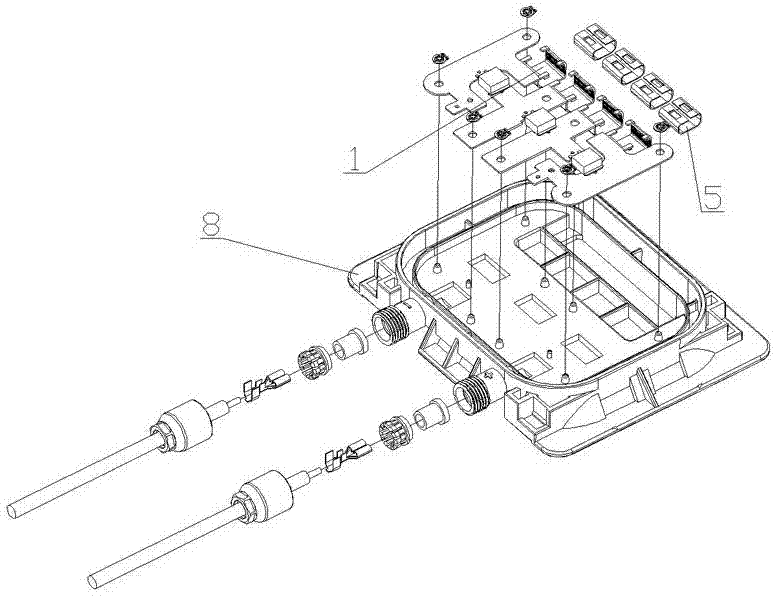

[0019] see figure 1 and Figure 4 , the metal conductive sheet 1 and the circlip 5 are installed in the box body 8. When assembling, first open the movable buckle 3, push the circlip 5 into the accommodating hole 2 from one side, and then close the movable buckle 3 to fix the circlip 5 In the storage hole 2. During use, only need to use tools, such as pliers, insert the two through holes 7 on the circlip 5 and clamp them...

Embodiment 2

[0021] see Figure 5 , different from Embodiment 1, there is a flanging 4 between the upper opening of the circlip 5 and the through holes 7 on both sides. Tighten the circlip 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com