Ventilated channel board of motor rotor

A technology for motor rotors and ventilation slots, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., which can solve the problems of shortening the service life of the motor, reducing the interference, and short ventilation slots, etc., to achieve slow down The process of damage aging, the possibility of reducing noise, the effect of high overall flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

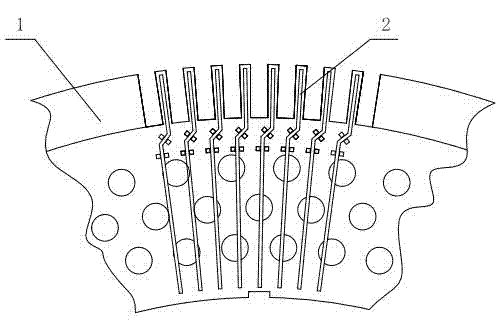

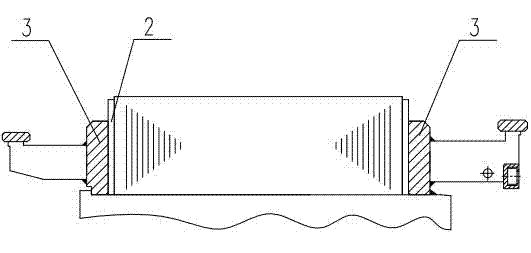

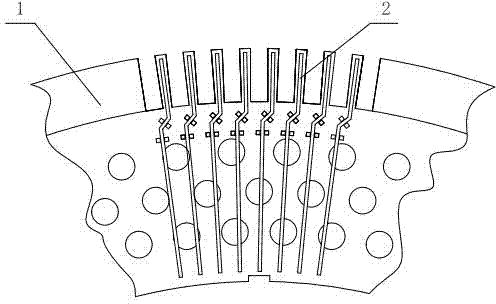

[0012] Such as figure 1 As shown, compared with the existing short ventilation slots, the ventilation slots 2 included in the present invention are lengthened downwards and extend to the inner diameter of the rotor ventilation slot bottom plate 1, that is, the length of the ventilation slots 2 is basically equal to the ventilation slot bottom plate 1 The annular width, and the assembly welding is carried out orthogonally to the bottom plate 1 of the rotor ventilation slot. Due to the lengthening of the ventilation slots 2, the welding contact surface is increased, so the firmness after welding is increased. Such as figure 2 As shown, after the armature pressure ring 3 presses the bottom plate 1 of the ventilation slot, it presses on the ventilation slot plate 2 of the same height at the same time, and is in close contact with the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com