Optical connector apparatus

An optical connector and connector technology, applied in the direction of instruments, connections where permanent deformation works, optics, etc., can solve the problem of not providing a cutout, and achieve the effects of reducing the elastic coefficient, reliable electrical connection, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

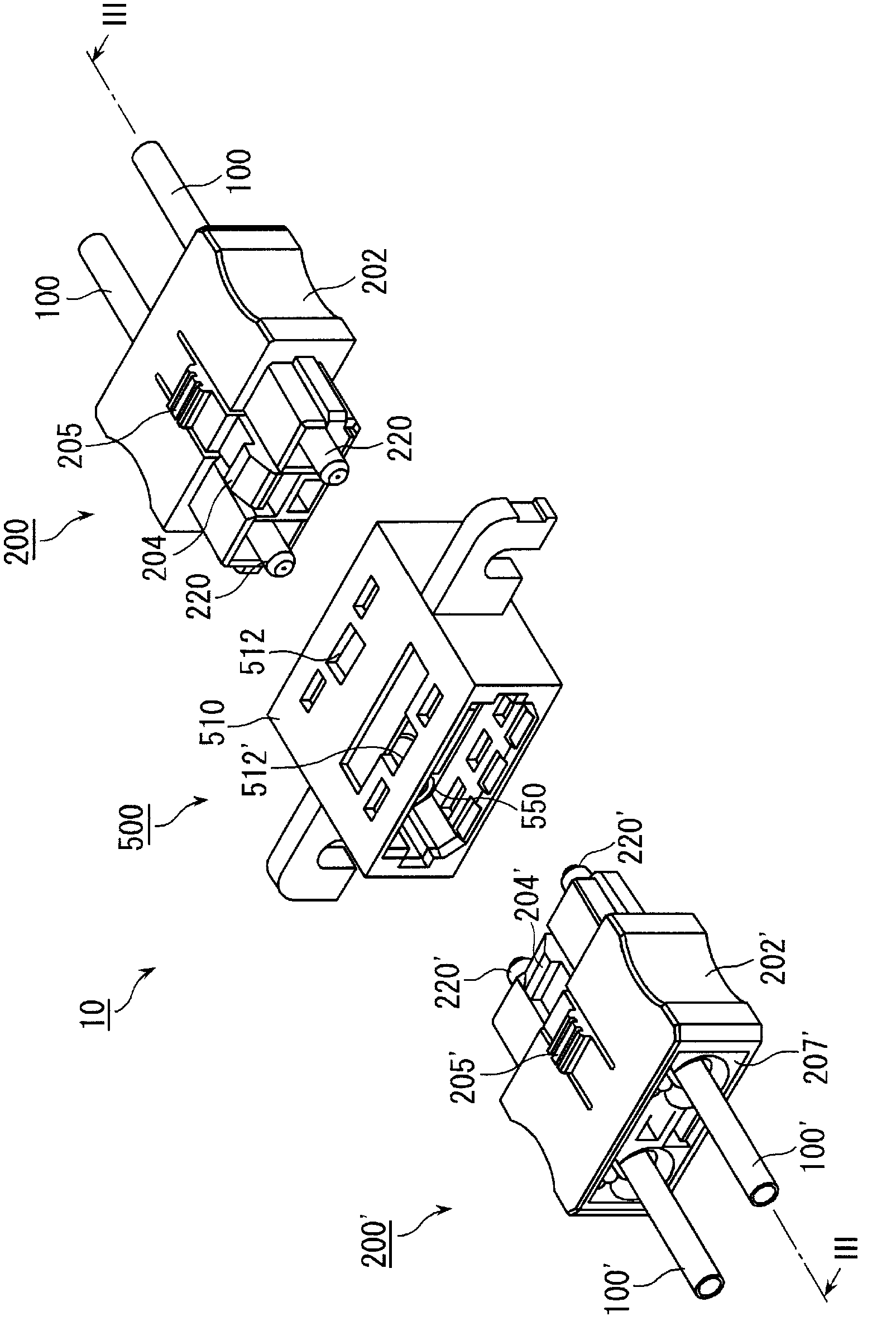

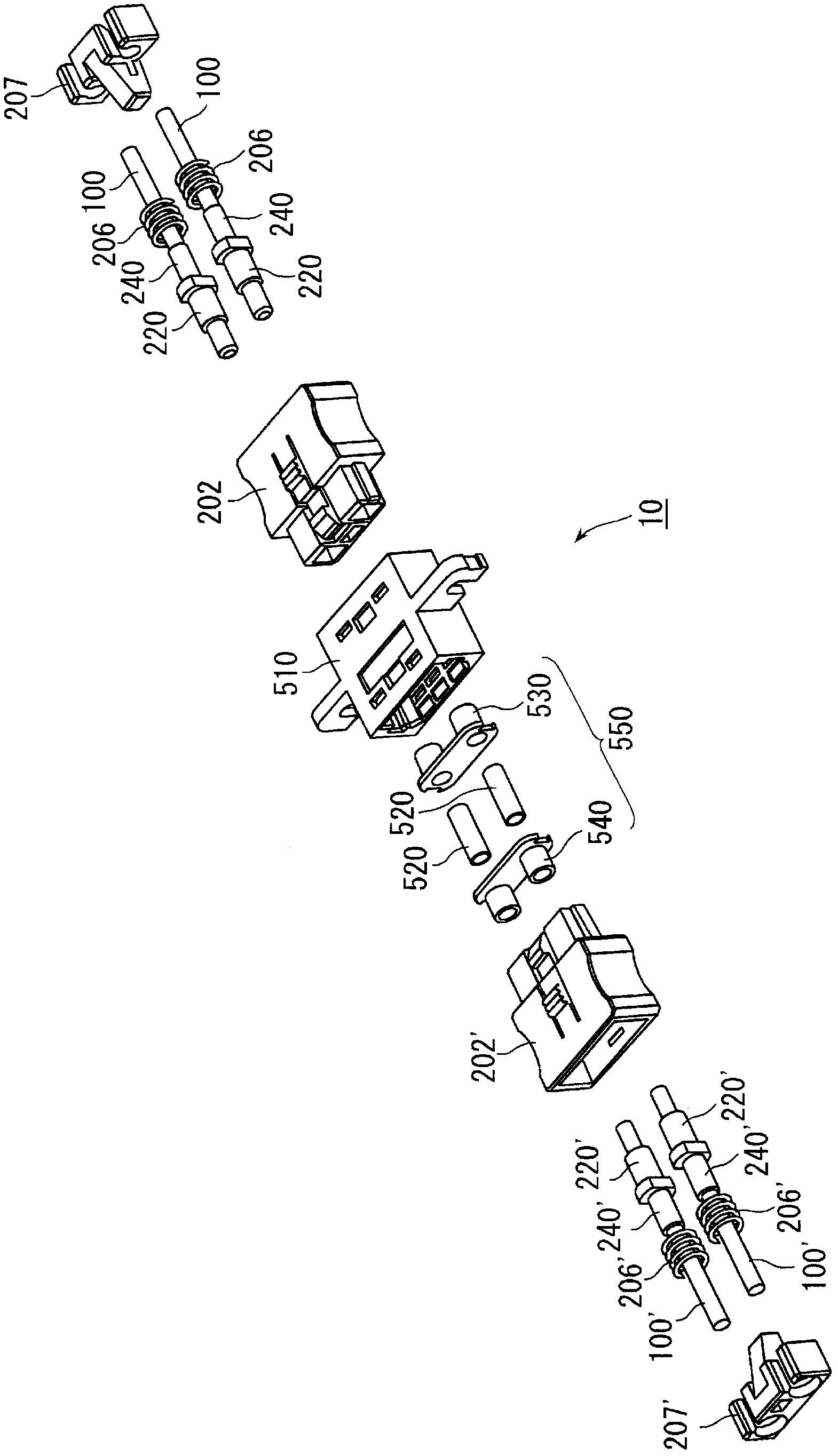

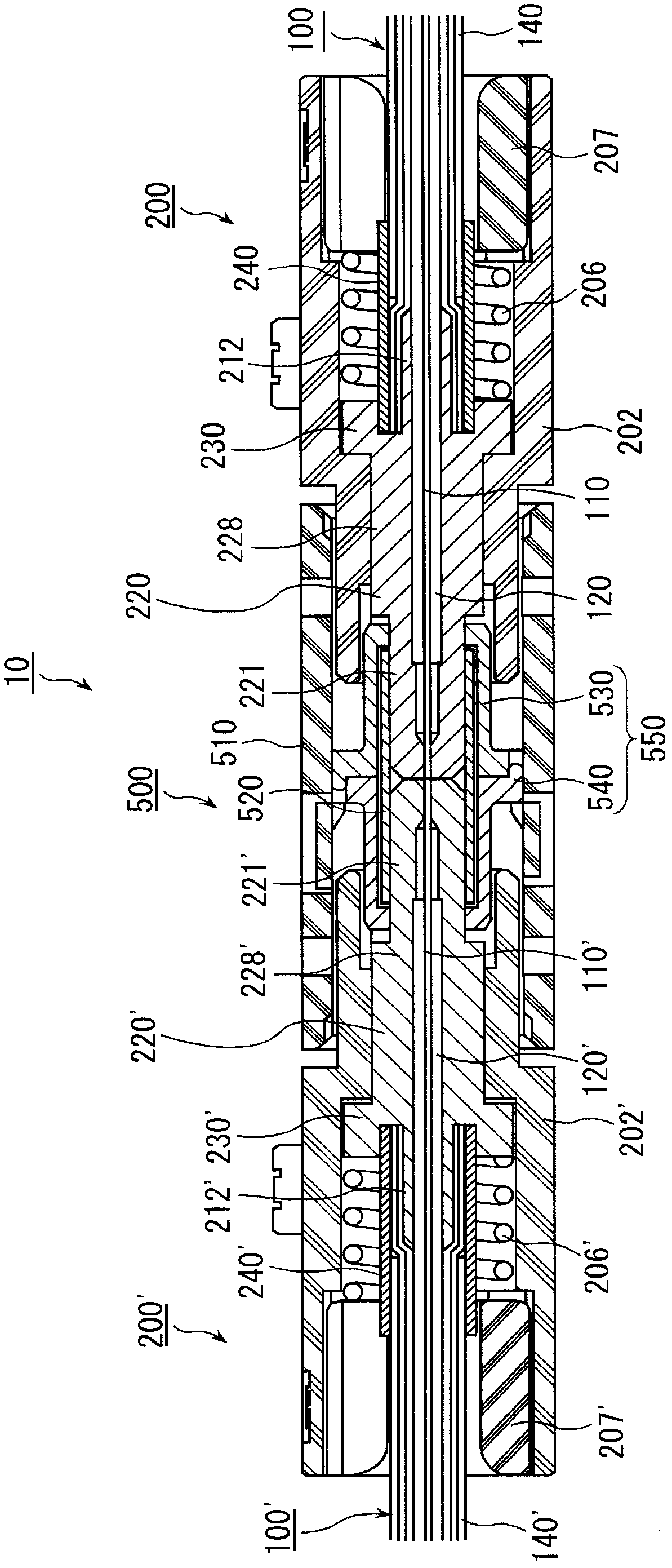

[0092] The optical connector device according to the first embodiment of the present invention is a device in which both ferrules are connected by being held by a connecting member. As a first embodiment, an optical connector device including two connectors and an adapter that relays them will be described. Such as Figure 1 to Figure 3 As shown, the optical connector device 10 has: a first connector 200 connected to the first photoelectric composite cable 100; a second connector 200' connected to the second photoelectric composite cable 100'; The adapter 500 relays the connection with the second connector 200'.

[0093] Such as image 3 As shown, the first connector 200 according to this embodiment includes a first ferrule 220 , and the first ferrule 220 is connected to the first photoelectric composite cable 100 . In addition, the second connector 200' has a second ferrule 220', and the second ferrule 220' is connected to the first photoelectric composite cable 100'. Her...

no. 2 approach

[0167] The optical connector device according to the first embodiment described above is a device for connecting an optoelectronic composite connector to another optoelectronic composite connector via an adapter, but the object to be connected via an adapter may be an optical element such as a photodiode.

[0168] like Figure 34 As shown, the optical connector device according to the second embodiment of the present invention includes a ferrule 220 connected to the photoelectric composite cable 100 , an optical element 800 such as a photodiode, and a housing 810 holding the optical element 800 . Here, the photoelectric composite cable 100 has the same structure as the photoelectric composite cable in the first embodiment, and the ferrule 220 uses the metal type in the first embodiment (refer to image 3 ) of the ferrule. Therefore, the ferrule 220 in this embodiment also includes the connected portion 221, the large-diameter portion 228, the shoulder portion 230, and a cylin...

no. 3 approach

[0172] The optical connector device according to the above-mentioned second embodiment holds the optical element in the housing, but the optical element may also be held in the housing. Figure 35 Adapter 900 as shown. Hereinafter, as a third embodiment of the present invention, an optical connector device including a connector and an adapter that holds an optical element and relays connection between the connector and the optical element will be described. It should be noted that, as the connector connected to the adapter 900, for example, the first connector 200 according to the above-mentioned first embodiment (refer to figure 1 ). At this time, as the ferrule held by the first connector 200, the ferrule 220 (refer to Figure 14 ), ferrule 220a (refer to Figure 10 ), ferrule 220b (refer to Figure 12 ), so below, the details of the connector and the ferrule are omitted, and only the adapter and the connecting member held by it are described.

[0173] like Figure 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com