Process for casting piston-ring blanks

A casting process and piston ring technology, which is applied in the casting process field of piston ring blanks, can solve the problems of low casting process yield, low work efficiency, and large riser ratio, and achieve stable product quality, increase yield, and meet performance requirements. The effect of indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment is used to produce piston ring blanks and φ102 oil ring blanks with a cylinder diameter of 160mm, and each process is operated as follows.

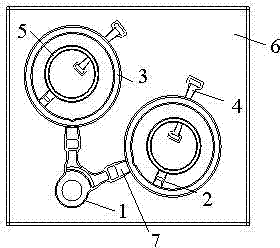

[0040] A. Forming plate: According to the cylinder diameter of the piston ring and the section coefficient of the piston model ring, design the collar plate required for modeling. The section coefficient is the ratio of the cross-sectional area of the piston ring to the section perimeter. In this embodiment, because a piston ring with a cylinder diameter of 160 mm is to be produced, and according to the requirements of the embodiment, the gas ring of this embodiment adopts a flat ring, so a flat ring model ring blank with a diameter of 160 mm must be produced. According to the section coefficient of the piston model ring The principle of matching, the section coefficient of the φ160 flat ring model ring is 1.14, and the section coefficient of the φ102 oil ring model ring is 1.08, which is relatively matched. Theref...

Embodiment 2

[0064] This embodiment is used to produce piston ring blanks and φ90 oil ring blanks with a cylinder diameter of 130 mm. The gas ring model ring is still a flat ring model ring. The process steps are the same as those in Embodiment 1, except that.

[0065] Step A: When making the collar plate, since the section coefficient of the φ130 flat ring model ring in this embodiment is 1.30, the diameter of the oil ring model ring matching the section coefficient of the φ130 flat ring model ring is 90mm, and the diameter of the φ90 oil ring model ring is The ring section coefficient is 1.317. Therefore, when making the collar plate, it is determined to use a flat ring model ring blank with a diameter of 130mm to nest an oil ring model ring with a diameter of 90mm.

[0066] The structure of the collar plate in this embodiment is different from that in Example 1. The collar plate in this embodiment includes a bottom plate, on which a sprue is arranged, and four flat sprues connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com