Pneumatic clamping and self-locking device and method for clamping workpieces by using same

A self-locking device and pneumatic clamping technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as injury to operators, burning of rotating parts, equipment damage, etc., to avoid accidents, Guaranteed reliability and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

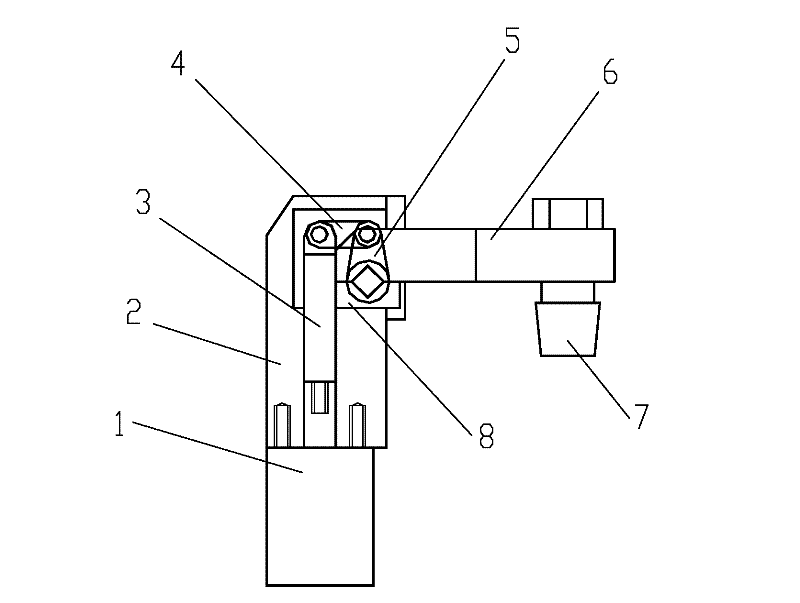

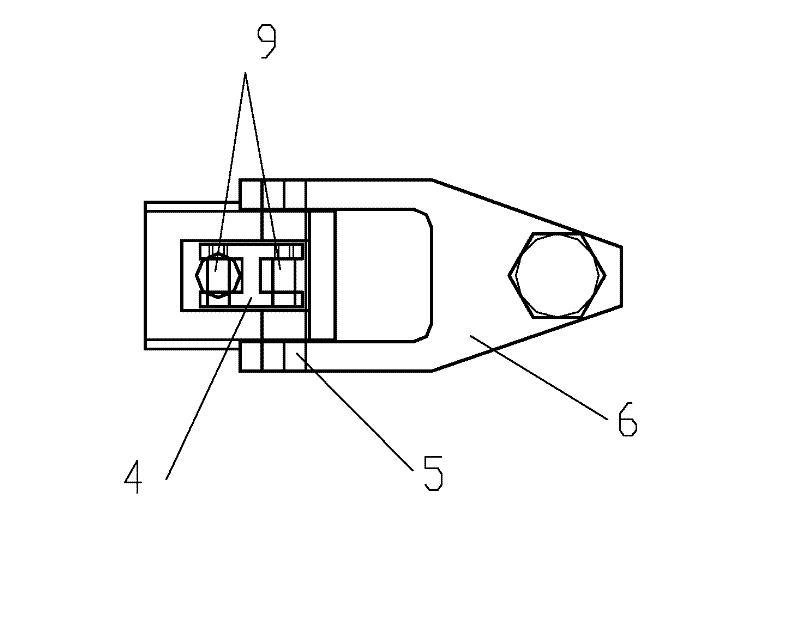

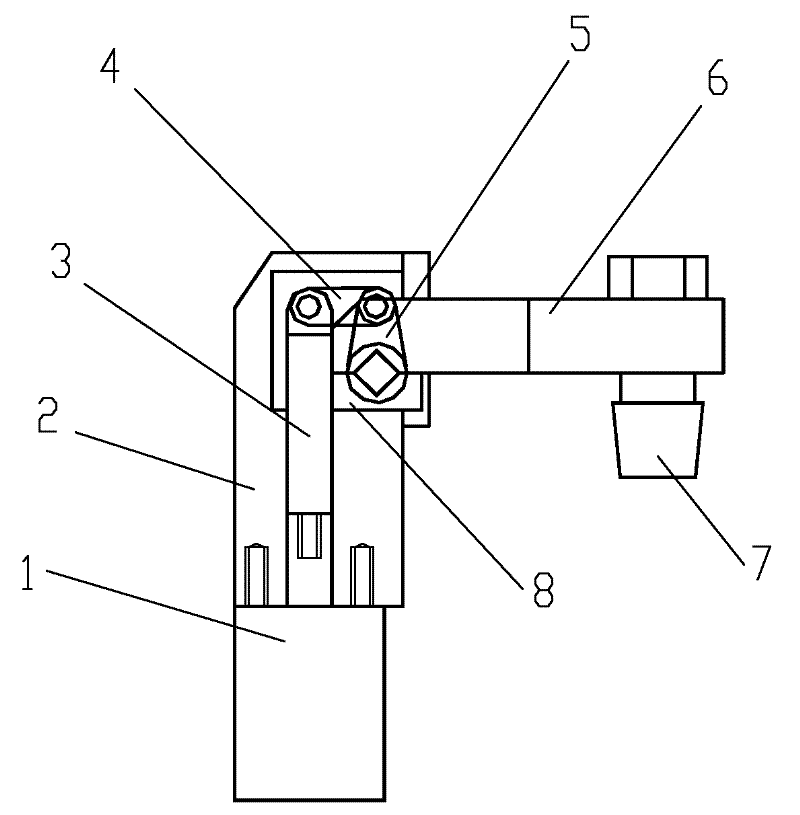

[0022] figure 1 It is a structural schematic diagram of the pneumatic clamping self-locking device of the present invention, figure 2 for figure 1 Schematic top view of the structure shown. Depend on Figure 1-2 Combining the shown structure, it can be seen that this kind of pneumatic clamping self-locking device includes a cylinder 1 fixed under the positioning seat 2. To connect, the other end of the first connecting rod 3 is connected with one end of the second connecting rod 4 through a threaded pin 9, and the threaded pin 9 is clearance fit with the holes on the first connecting rod 3 and the second connecting rod 4.

[0023] The other end of the second connecting rod 4 is connected with an end of the third connecting rod 5 by a threaded pin 9, the third connecting rod 5 is a crank connecting rod, the other end of the third connecting rod 5 is a crankshaft, and the crankshaft is connected to the positioning seat 2 The gaps on the upper and lower holes are matched, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com