Preparation method of position B element Y doped perovskite ceramic oxygen penetration film material

A perovskite-type, element-doped technology, applied in the field of inorganic oxygen-permeable membrane materials, can solve the problems of unstable material structure, low oxygen permeability, and affecting the working efficiency of materials, so as to improve the stability of oxygen permeability and oxygen permeability. The effect of high content and compact bulk structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

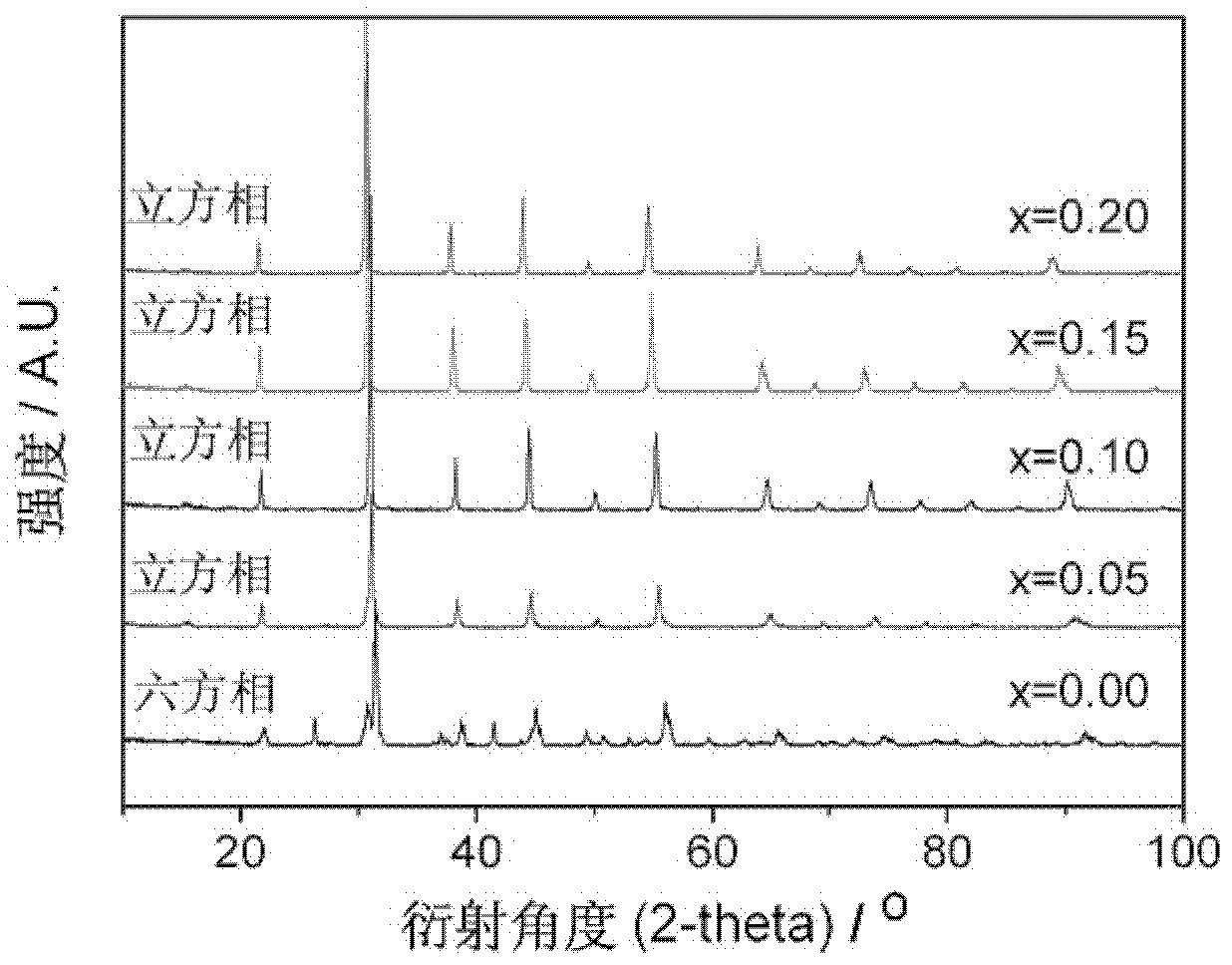

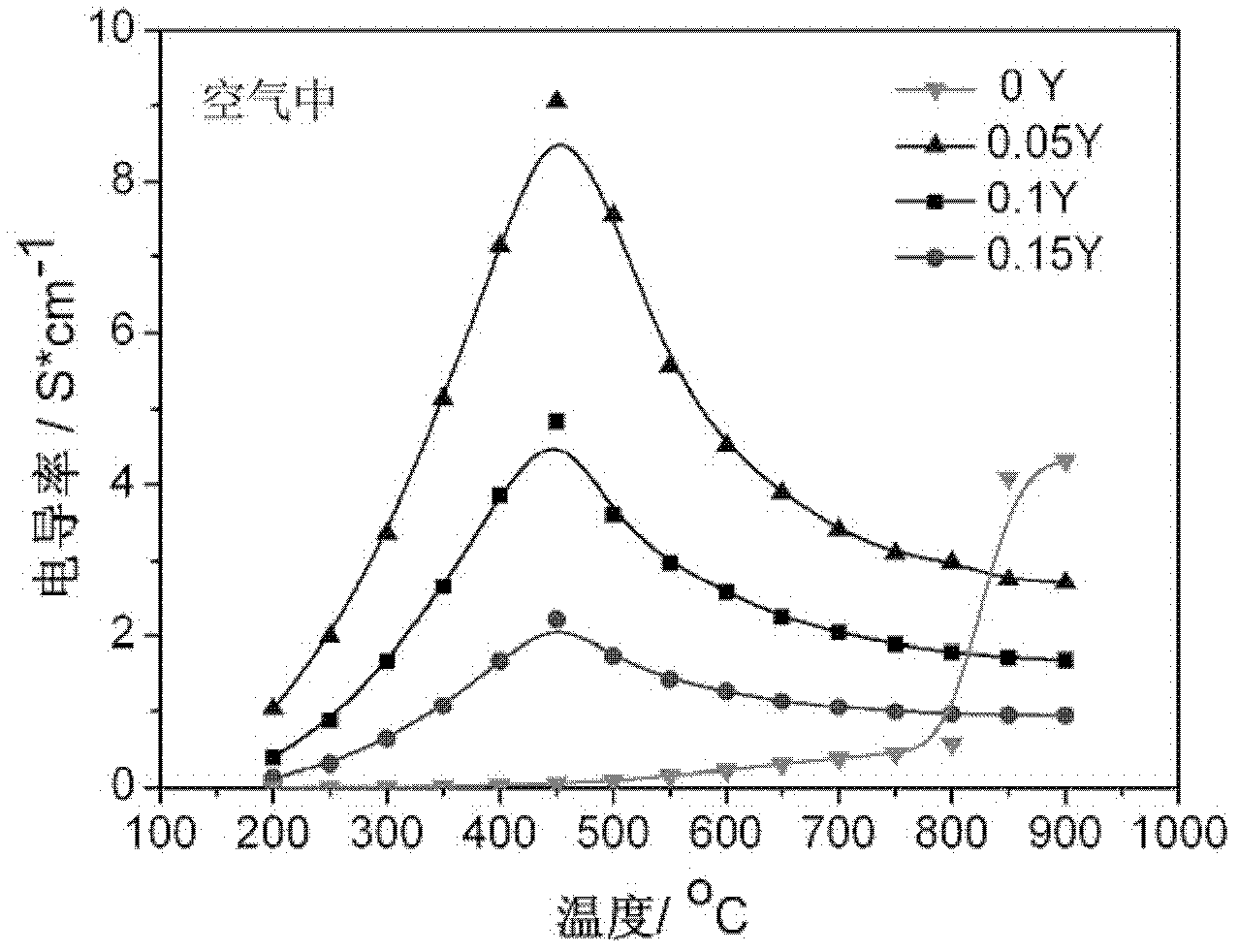

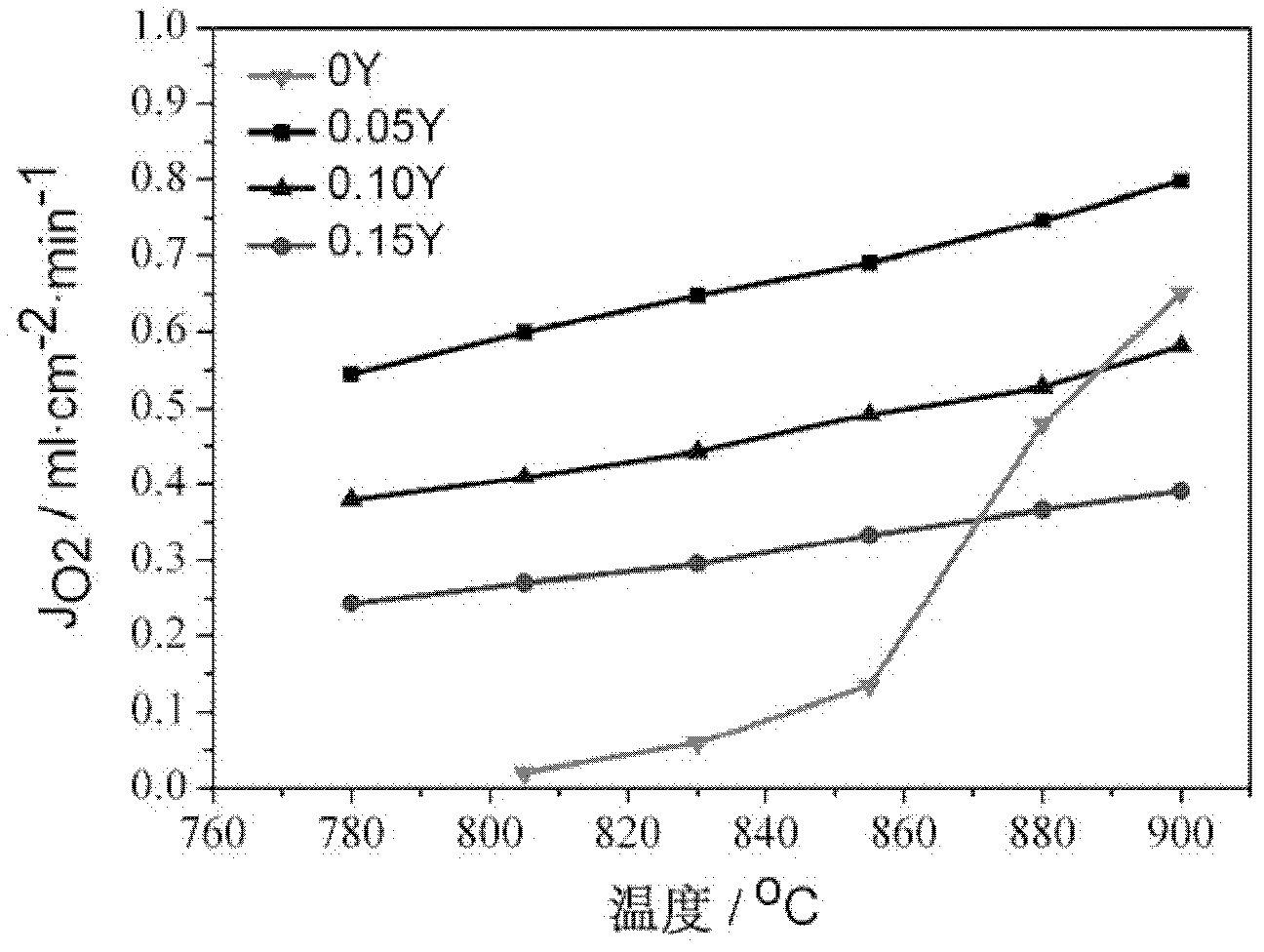

[0018] Example 1: BaFe 0.95 Y 0.05 o 3-δ Synthesis by solid phase reaction

[0019] With 19.734g of BaCO 3 (analytically pure), 0.5645g of Y 2 o 3 (analytical pure), 7.586g of Fe 2 o 3 (analytical pure) as raw material, that is, according to BaFe 0.95 Y 0.05 o 3-δ The mixture was prepared in the ratio of the elements, and alcohol was used as the medium, and ball milled in an agate ball mill tank at 200r / min for 3 hours. After mixing evenly, it was dried in an oven. After the dried material was calcined at 1000°C for 10 hours, it was ground into a powder with an agate mortar, and then ball milled with agate balls as the grinding medium at 200 r / min for 4 hours, and then put into a drying oven for drying. After the drying is complete, grind it evenly in a mortar, add 1.0wt.% PVA to mix and dry it, and then dry press it in a steel casting mold. The pressed sample strip is heated to 1320°C in a high-temperature furnace, and after 10 hours of heat preservation, it is mad...

Embodiment 2

[0020] Example 2: BaFe 0.925 Y 0.075 o 3-δ Synthesis by solid phase reaction

[0021] With 19.734g of BaCO 3 (analytically pure), 0.847g of Y 2 o 3 (analytical pure), 7.386g of Fe 2 o 3 (analytical pure) as raw material, that is, according to BaFe 0.925 Y 0.075 o 3-δ The mixture was prepared in the ratio of the elements, and alcohol was used as the medium, and ball milled in an agate ball mill tank at 200r / min for 3 hours. After mixing evenly, it was dried in an oven. After the dried material was calcined at 1000°C for 10 hours, it was ground into a powder with an agate mortar and then ball milled with an agate ball as a grinding medium at 200 r / min for 4 hours, and then put into a drying oven for drying. After the drying is complete, grind it evenly in a mortar, add 1.0wt.% PVA to mix and dry it, and then dry press it in a steel casting mold. The pressed sample strip is heated to 1340°C in a high-temperature furnace, and after 10 hours of heat preservation, it is m...

Embodiment 3

[0022] Example 3: BaFe 0.9 Y 0.1 o 3-δ Synthesis by solid phase reaction

[0023] With 19.734g of BaCO 3 (analytically pure), 1.129g of Y 2 o 3 (analytical pure), 7.1865g of Fe 2 o 3 (analytical pure) as raw material, that is, according to BaFe 0.9 Y 0.1 o 3-δ The mixture was prepared in the ratio of the elements, and alcohol was used as the medium, and ball milled in an agate ball mill tank at 200r / min for 3 hours. After mixing evenly, it was dried in an oven. After the dried material was calcined at 1000°C for 10 hours, it was ground into a powder with an agate mortar and then ball milled with agate balls as the grinding medium at 200r / min for 4 hours, and then put into a drying oven for drying. After the drying is complete, grind it evenly in a mortar, add 1.0wt.% PVA to mix and dry it, and then dry press it in a steel casting mold. The pressed sample strip is heated to 1350°C in a high-temperature furnace, and after 10 hours of heat preservation, it is made into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com