Steel tube concrete superposed column with mild steel casing outer packed concrete at bottom and preparation method thereof

A technology of steel pipe concrete and outsourcing concrete, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of poor fire performance, occupied space, and limited deformation capacity of steel pipe concrete columns, so as to improve the horizontal and vertical bearing capacity, increase Effects of large usable area and reduced earthquake action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

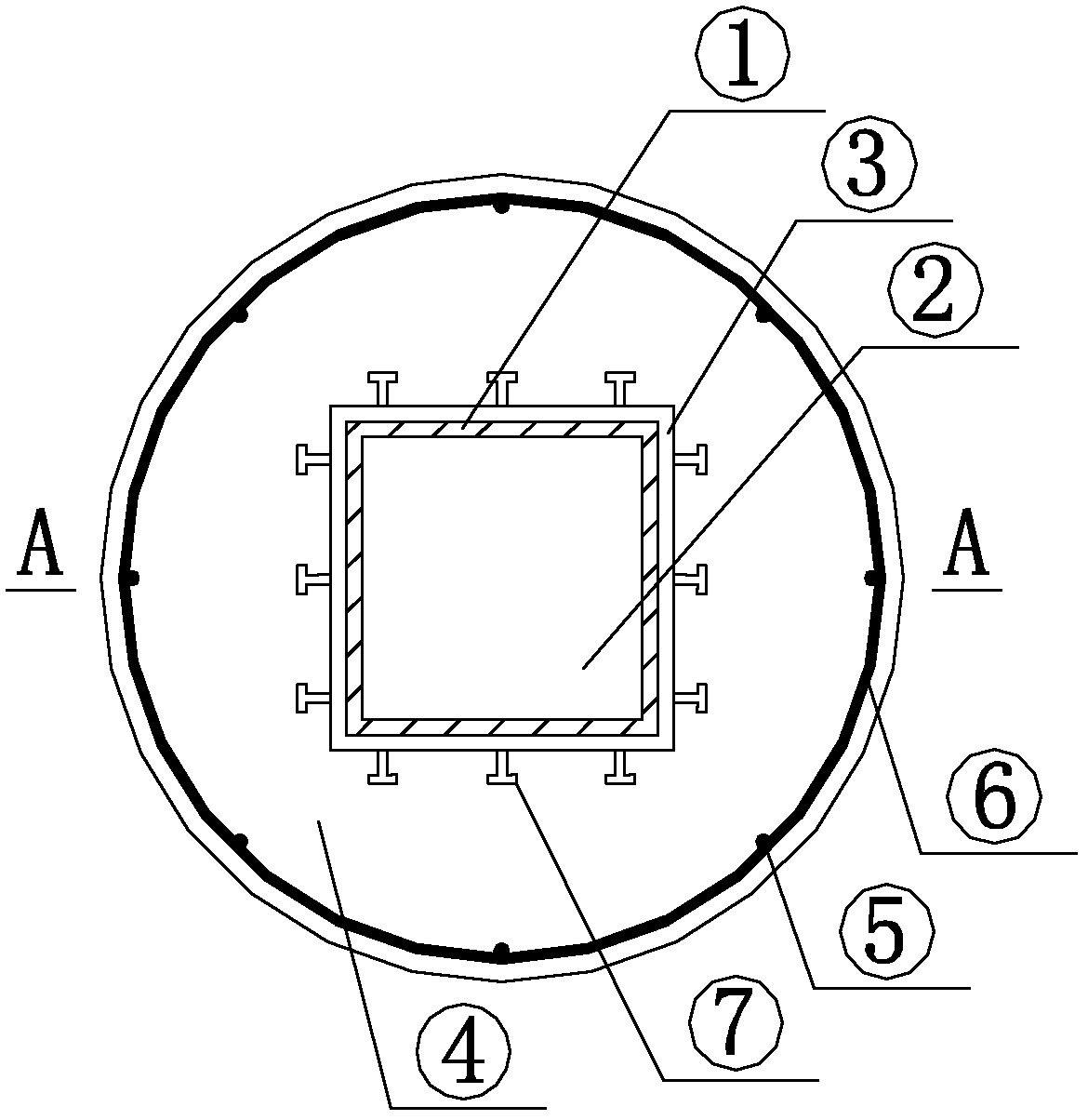

[0033] A structural form of concrete-filled steel tube composite columns with soft steel sleeves at the bottom and concrete outsourcing and its method is as follows figure 1 As shown, its cross-section is shown in Figure 5 As shown, it includes the inner steel pipe 1, the inner concrete 2 of the steel pipe, the outer concrete 4 of the steel pipe, the longitudinal reinforcement 5, the stirrup 6 and the mild steel casing 3; The external concrete 4, the steel pipe external concrete 4 is pre-embedded with longitudinal reinforcement 5 and stirrup 6; the outer side of the bottom wall of the internal steel pipe 1 is wrapped with a mild steel sleeve 3, and the mild steel sleeve 3 extends into the lower ground or the top surface of the foundation 9 and anchor with it. The concrete-filled steel tube composite column has a circular cross-section. The inner steel pipe 1 is a rectangular steel pipe. The height of the mild steel casing 3 above the ground or foundation top surface 9 is 1...

Embodiment 2

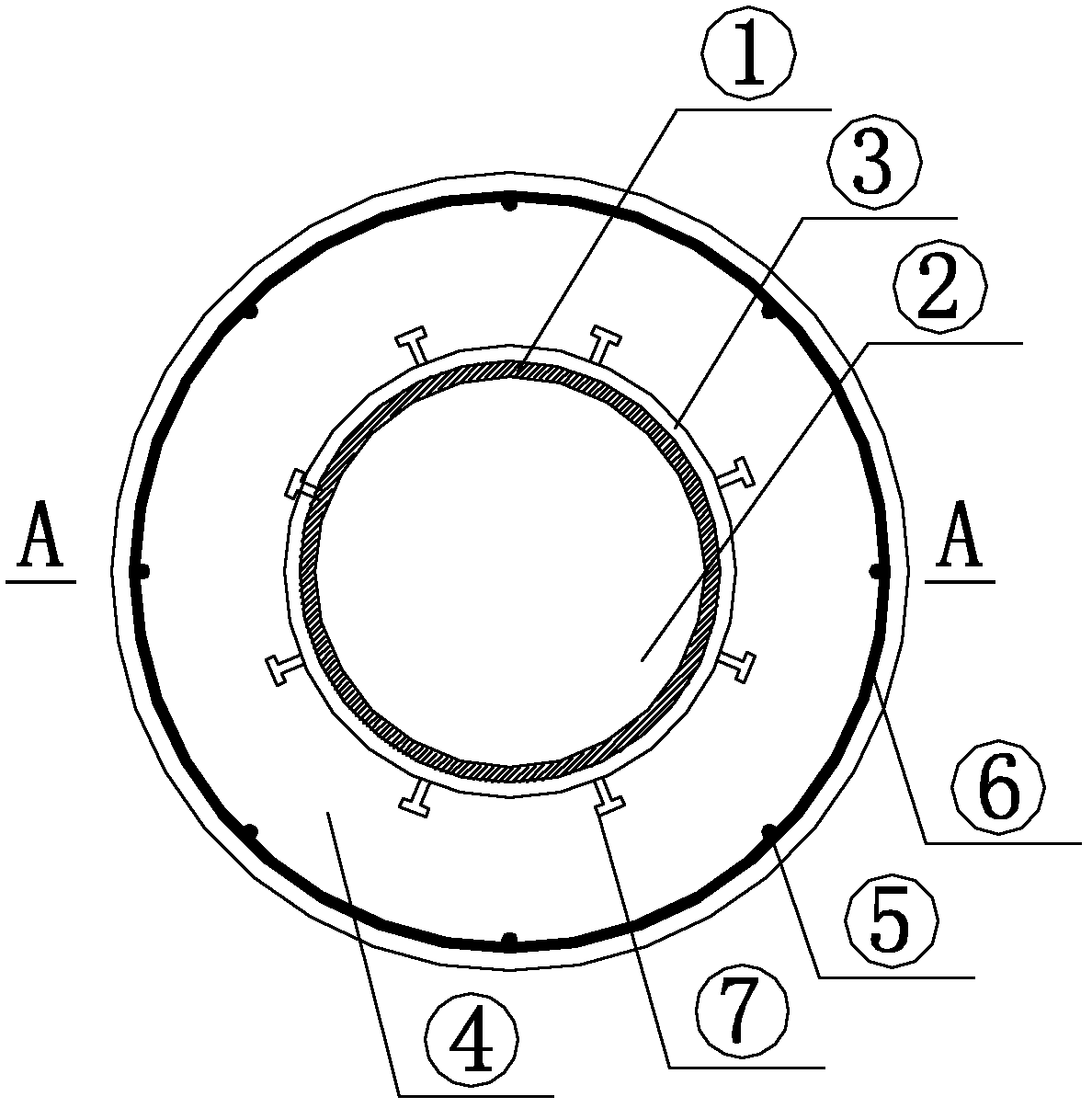

[0043] Concrete-filled steel tube composite column with soft steel casing at the bottom and concrete outsourcing and another structural form of the method is as follows figure 2 As shown, its cross-section is shown in Figure 5 shown. The outer shape of the composite column is circular, and the inner steel pipe 1 is also circular, and the other structural forms are the same as in Embodiment 1.

Embodiment 3

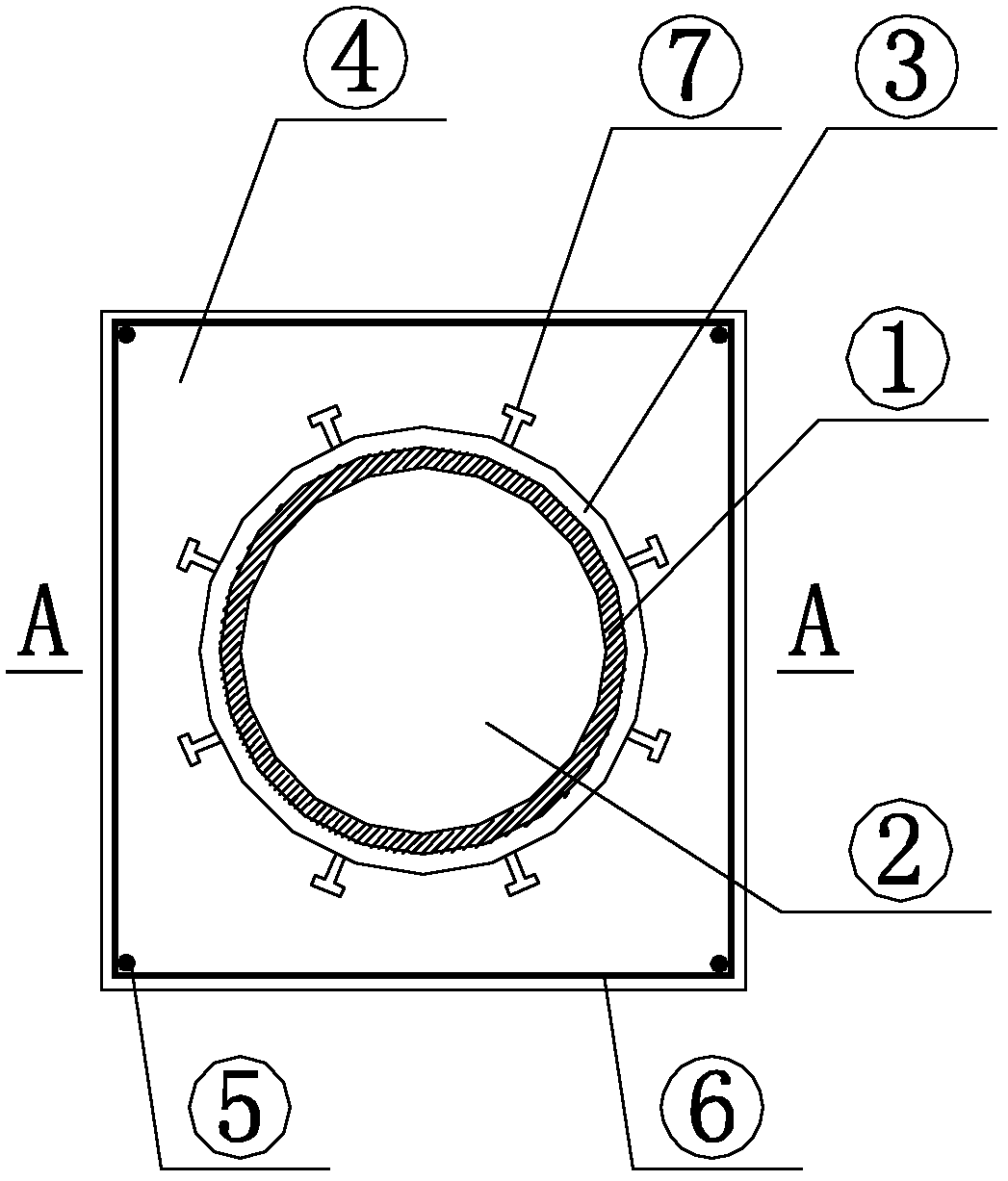

[0045]Concrete-filled steel tube composite column with soft steel casing at the bottom and concrete outsourcing and another structural form of the method is as follows image 3 As shown, its cross-section is shown in Figure 5 shown. The outer shape of the composite column is rectangular, and the inner steel pipe 1 is circular, and other structural forms are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com