Wind-resistant H-shaped steel column for high-speed railway contact network and method for determining aperture ratio of wind-resistant H-shaped steel column

A technology for high-speed railways and determination methods, applied in building types, buildings, towers, etc., to achieve the effects of strong controllability, improved wind resistance stability, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

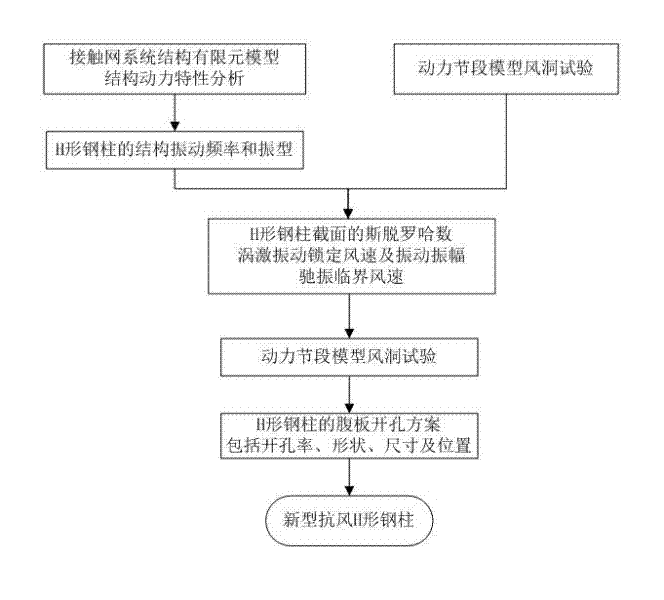

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in combination with specific embodiments.

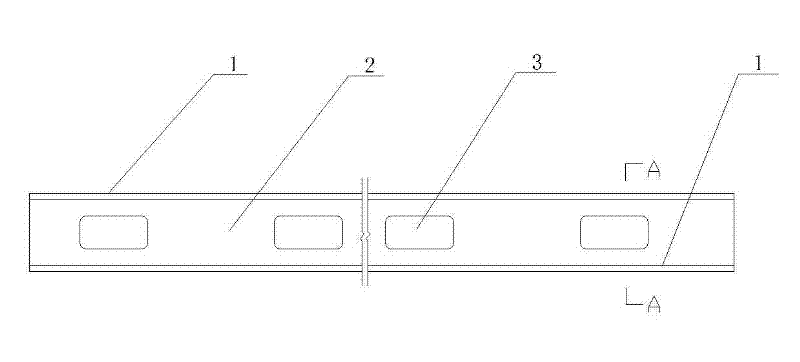

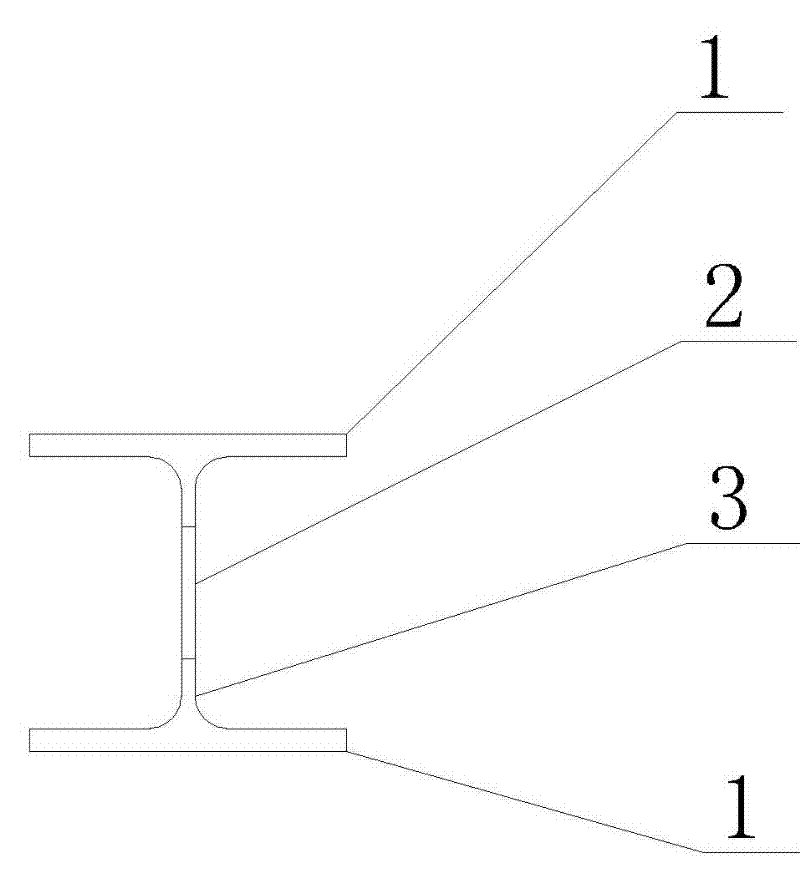

[0039] The H-shaped steel column body currently used in the catenary of high-speed railways is composed of flanges 1 parallel to each other on both sides and webs 2 perpendicular to the flanges 1 in the middle. Set rounded corners at the connection between 2. In order to improve the wind-resistant stability of the H-shaped steel column, the wind-resistant H-shaped steel column of the high-speed railway catenary is provided with an opening 3 on the web 2 of the steel column, and the area of the opening 3 occupies 100% of the web. 2 17% to 40% of the total area; the shape of the opening 3 is rectangular, which can be rectangular or square; the hole size of the opening 3 in the axial direction of the steel column is the same as that in the vertical direction of the steel column ratio of 2 to 2.5; the hole size of the opening 3 in the axial direction of the vertical steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com