Winding ring device, winding device and tire bead winding system

A technology for winding rings and beads is applied in the field of auxiliary equipment for tire production, which can solve the problems of winding quality, inconsistent tension, and low winding quality, and achieve the effects of high winding stability, no material waste, and improved winding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

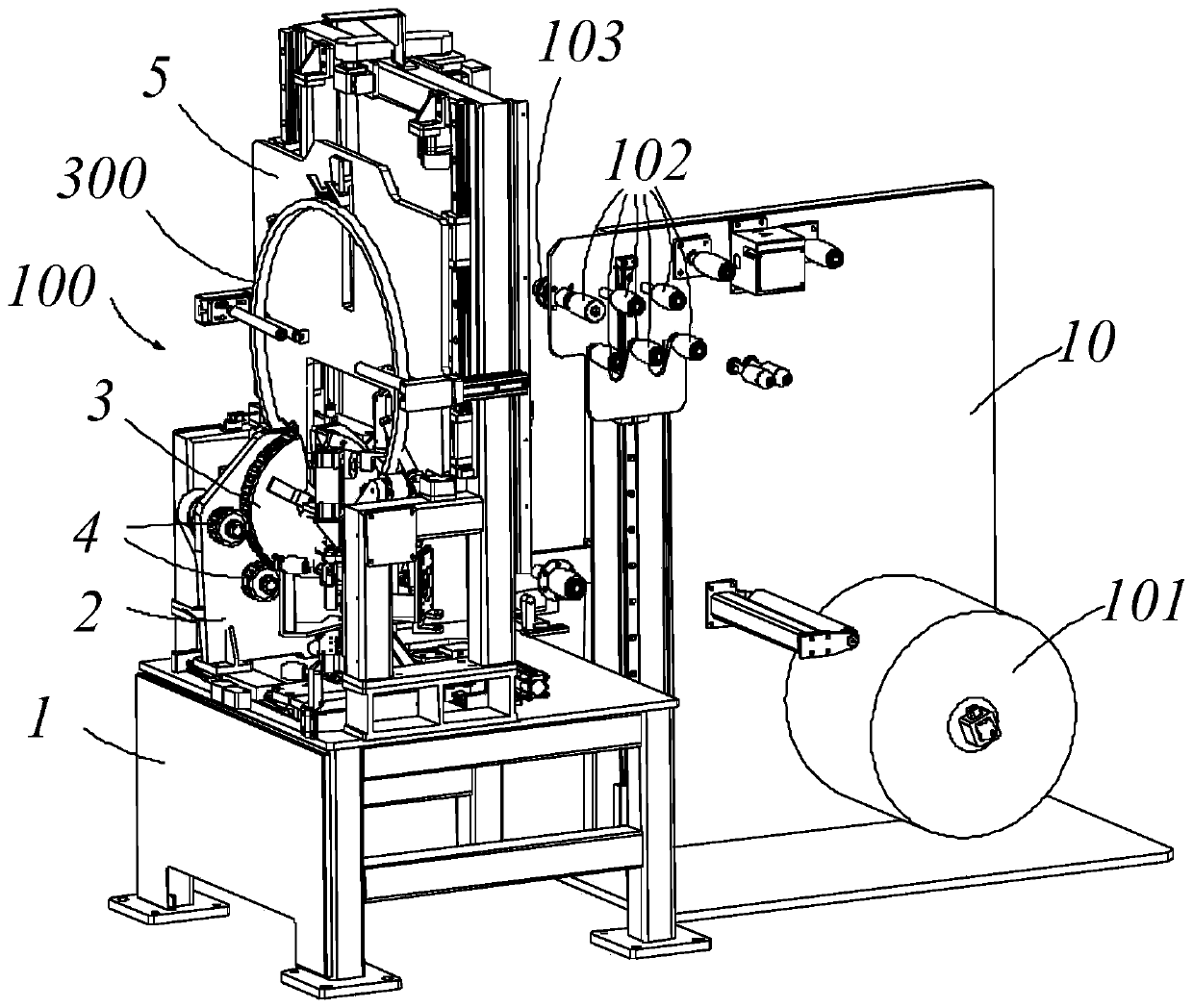

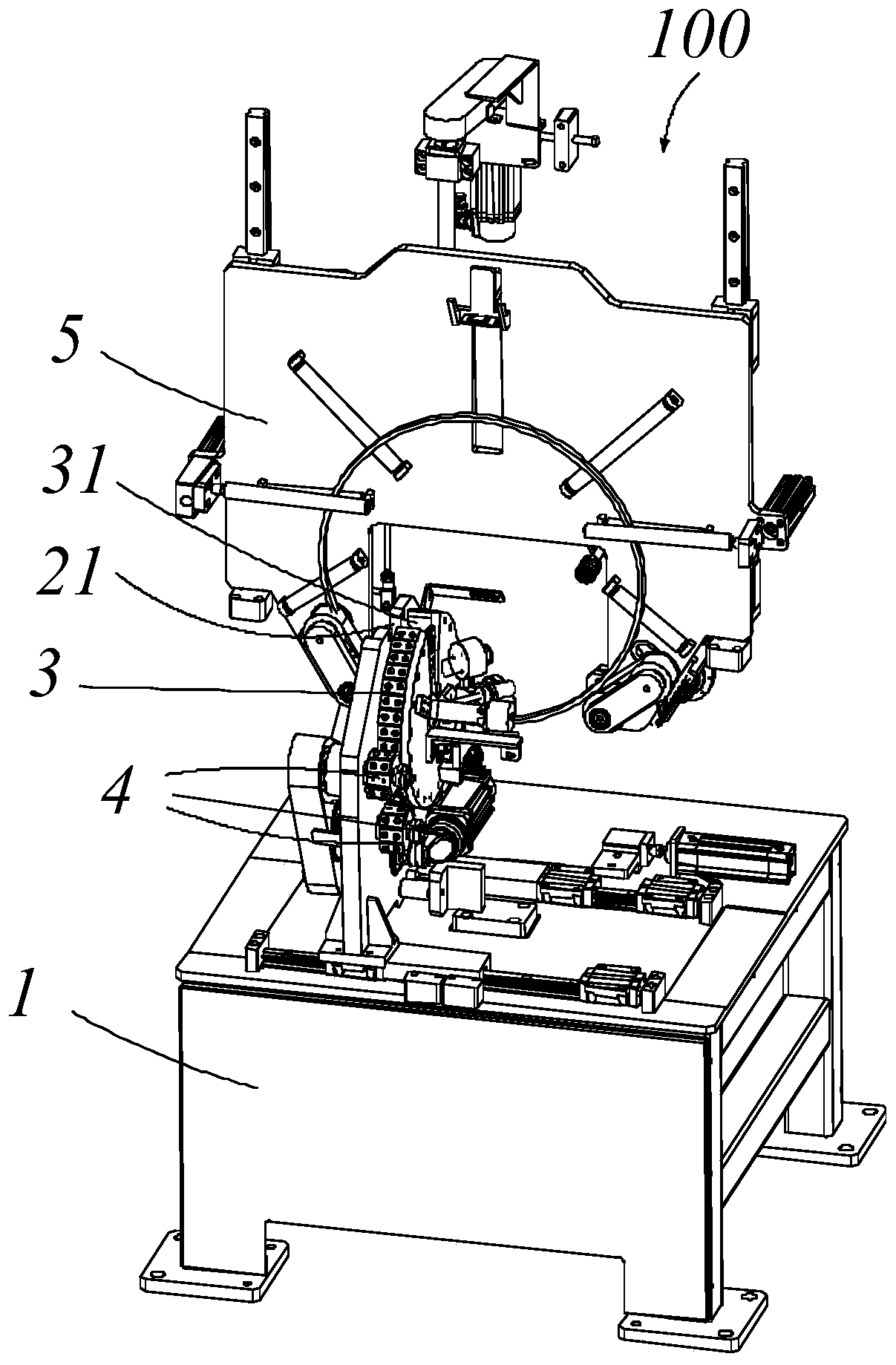

[0039] Such as Figure 1-Figure 7 , Figure 10-Figure 13 As shown, the present invention discloses a winding ring device 100 applied to a winding device, and the winding ring device 100 is used for spirally winding a strip 200 onto a bare bead 300 to form a bead. The winding ring device 100 includes a base 1 , a vertical plate 2 vertically arranged on the base 1 , a winding ring component 3 arranged on the vertical plate 2 , and a first driving mechanism 4 for driving the winding ring component 3 to rotate around its center. The wrapping ring part 3 is ring-shaped, and the wrapping ring part 3 is provided with a notch 31 , and the vertical plate 2 is provided with a notch 21 which basically coincides with the notch 31 . After the bare bead 300 enters the center of the winding ring component 3 from the notch 31 and the cutout 21 , the bare bead 300 and the winding ring component 3 cross each other, and the end surface of the bare bead 300 is perpendicular to the end surface of...

Embodiment 2

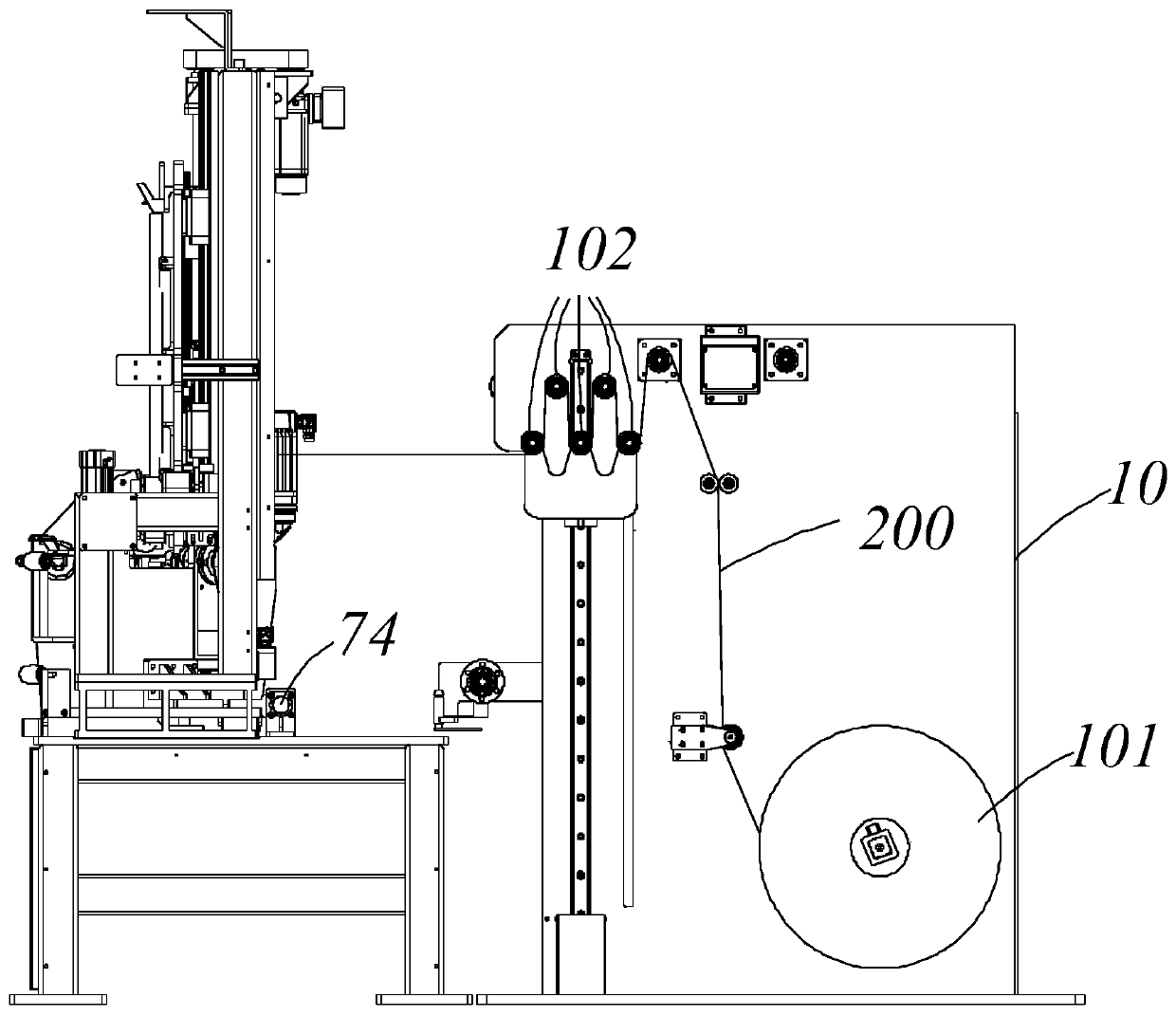

[0055] Such as Figure 1-13 As shown, the winding device in this embodiment includes all the components in Embodiment 1, and also includes a transmission mechanism 6 slidably arranged on the base 1 . Specifically, the transmission mechanism 6 is arranged on the base 1 through a guide rail slider mechanism 7, and the guide rail slider mechanism 7 includes two rows of guide rails 71 arranged on the base 1, a slider 72 slidingly arranged on each guide rail 71, The bottom plate 73 arranged on the two rows of sliders 72 and the driving cylinder 74 for driving the bottom plate 73 to move. The driving cylinder 74 can drive the bottom plate 73 to slide along the guide rail 71 , thereby driving the transmission mechanism 6 to move away from or close to the winding ring component 3 .

[0056] The transmission mechanism 6 includes a base plate 61 , a first driving source (not labeled) disposed on the base plate 61 , and a rotating component 62 disposed at a driving end of the first driv...

Embodiment 3

[0064] Such as Figure 1-13 As shown, this embodiment also provides a bead winding system with the winding device of Embodiment 2, and the bead winding system is used for fully automatic helical winding of the rubber strip 200 onto the bare bead 300 . The bead winding system includes a feeding device 10 , the winding device in Embodiment 2 above, and a cutting mechanism 20 for cutting a strip 200 .

[0065] The feeding device 10 includes a material roll 101, a plurality of storage rollers 102, an encoder 103 connected to the last storage roller 102 in the conveying direction, and a total drive source (not shown). The material roll 101 is discharged through multiple storage rollers. The material stored in the roller 102 is transferred to the winding ring device 100. After the bare bead 300 is placed on the winding ring device 100 driven by the second driving mechanism 5, the second driving mechanism 5 cooperates with the winding ring device 100. movement to helically wind the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com