Low-entropy mixed combustion gas-liquified substance engine

An internal combustion engine and engine technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of low heat transfer coefficient of liquefied gas, engines not widely used, complex systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

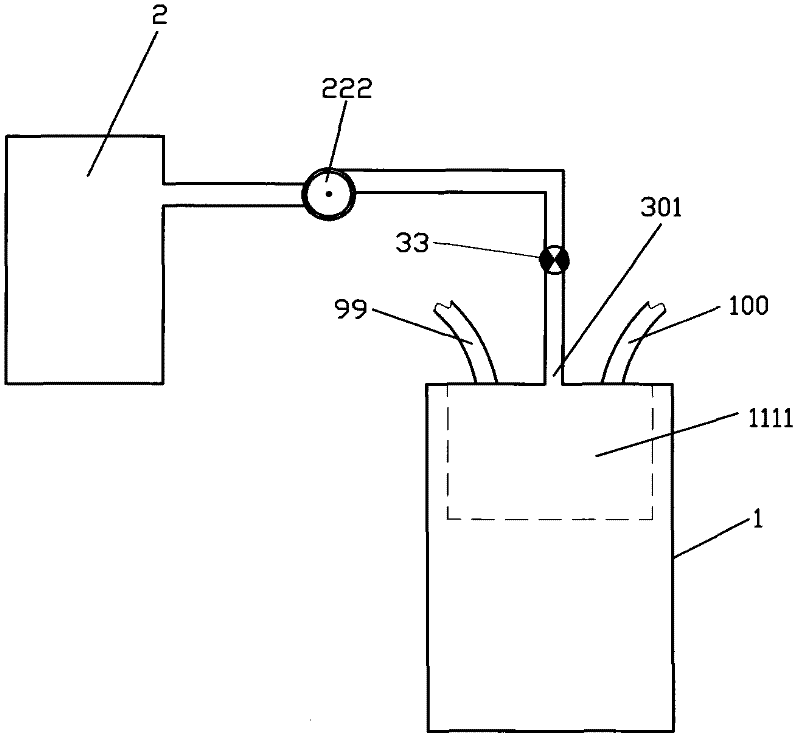

[0066] Such as figure 1 The shown low-entropy mixed-combustion gas liquefaction engine includes an internal combustion engine 1 and a gas liquefaction storage tank 2, and an intake passage 99 and an exhaust passage 100 are arranged on the combustion chamber 1111 of the internal combustion engine 1, and in the combustion chamber The wall of 1111 is provided with a high-pressure gas liquefied substance inlet 301, and a gas liquefied substance control valve 33 is set at the high-pressure gas liquefied substance inlet 301, and the gas liquefied substance storage tank 2 passes through the high-pressure liquid pump 222, the gas liquefied substance in sequence, The liquefied substance control valve 33 and the high-pressure gas liquefied substance inlet 301 communicate with the combustion chamber 1111, and the gas liquefied substance in the gas liquefied substance storage tank 2 can be in the form of liquid or in the form of critical state or in the form of super The form of high-pre...

Embodiment 2

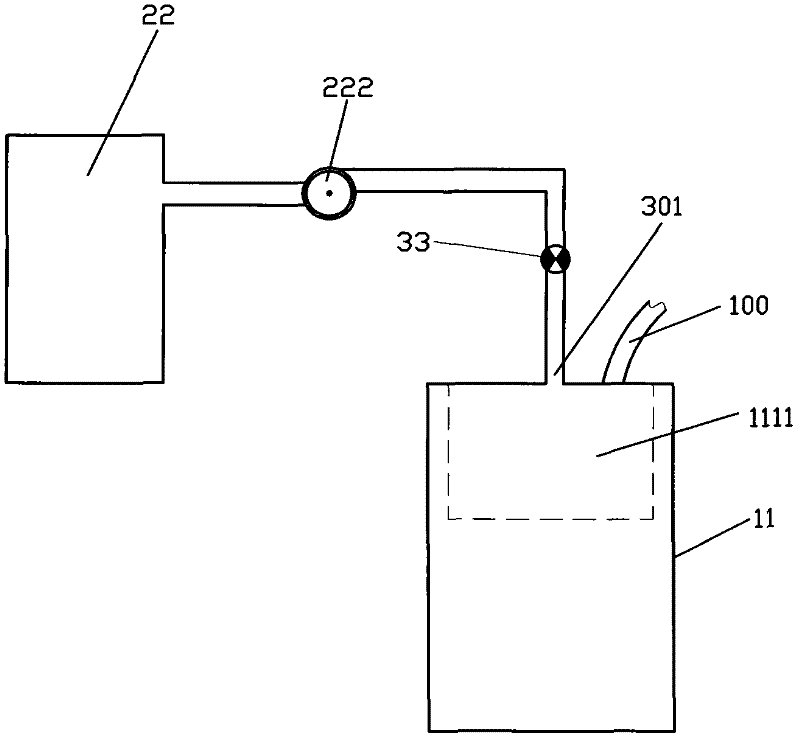

[0070] Such as figure 2The shown low-entropy mixed-combustion gas liquefied product engine comprises an explosive discharge engine 11 and a gas liquefied product storage tank 2, and the gas liquefied product storage tank 2 is set as an oxygen-containing gas liquefied product storage tank 22, and in the explosive discharge engine 11 The combustion chamber 1111 is provided with a high-pressure gas liquefied product inlet 301 and an exhaust duct 100, a gas liquefied product control valve 33 is provided at the high-pressure gas liquefied product inlet 301, and the oxygen-containing gas liquefied product storage tank 22 is passed through a high-pressure liquid pump. 222 communicates with the combustion chamber 1111 through the gas liquefied substance control valve 33 and the high-pressure gas liquefied substance inlet 301, and the oxygen-containing gas liquefied substance storage tank 22 can be in the form of liquid or Enter the combustion chamber 1111 in the form of critical stat...

Embodiment 3

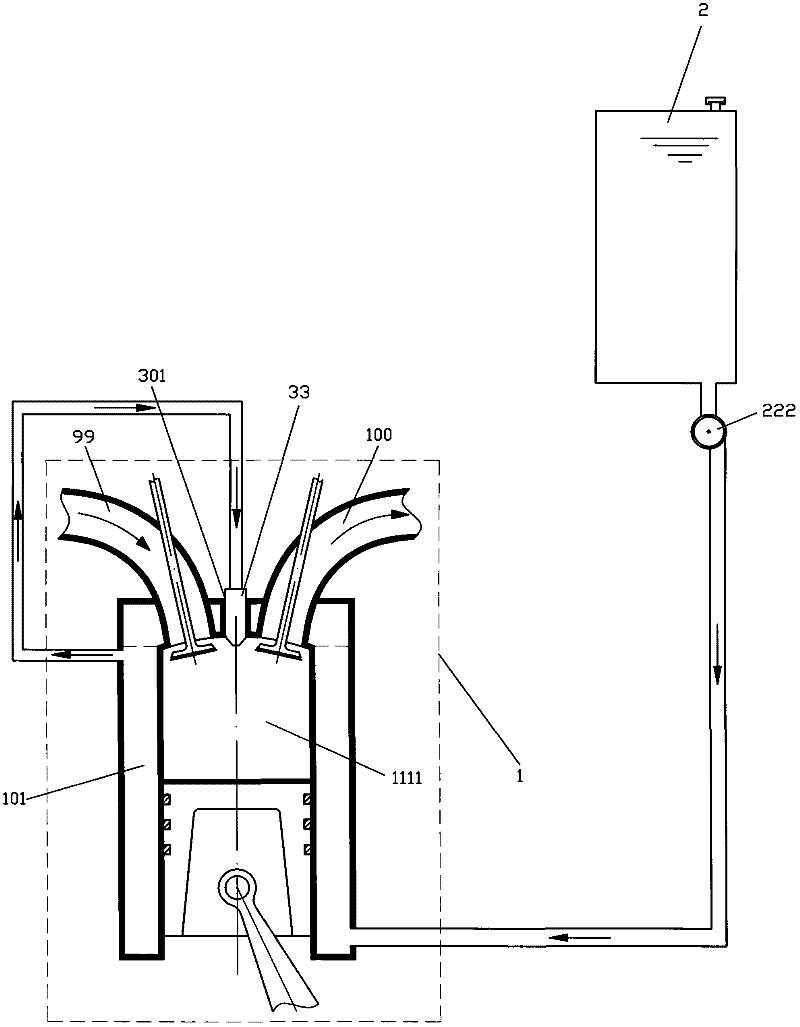

[0074] Such as image 3 The difference between the shown low-entropy mixed-combustion gas liquefied product engine and Embodiment 1 is that a high-pressure fluid channel 101 is provided in the wall of the combustion chamber 1111, and the gas liquefied product storage tank 2 passes through the high-pressure fluid channel in sequence. The liquid pump 222 , the high-pressure fluid channel 101 on the wall of the combustion chamber, the gas liquefied substance control valve 33 and the high-pressure gas liquefied substance inlet 301 communicate with the combustion chamber 1111 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com