Overstocked type zinc-air cell monomer

A zinc-air battery and monomer technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of complicated disassembly and regeneration, long electronic conductive path, inconvenient installation and use, etc., to increase the current overcut The area, the structure is reasonable, and the effect of reducing the loss of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

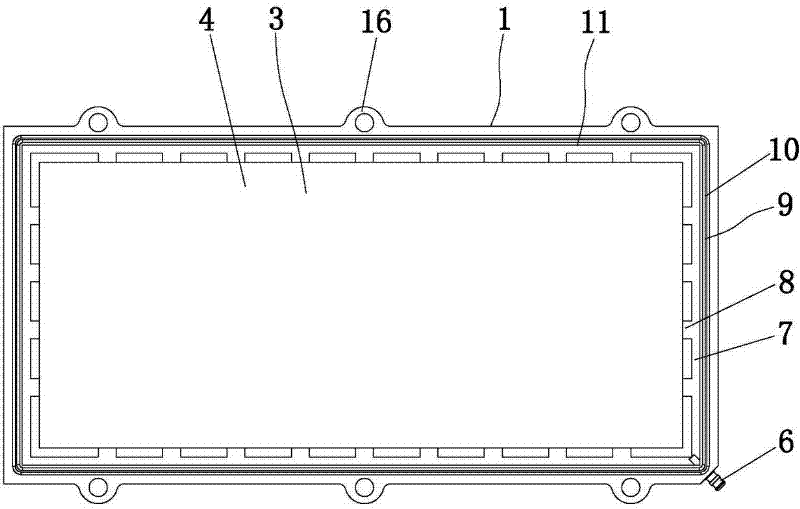

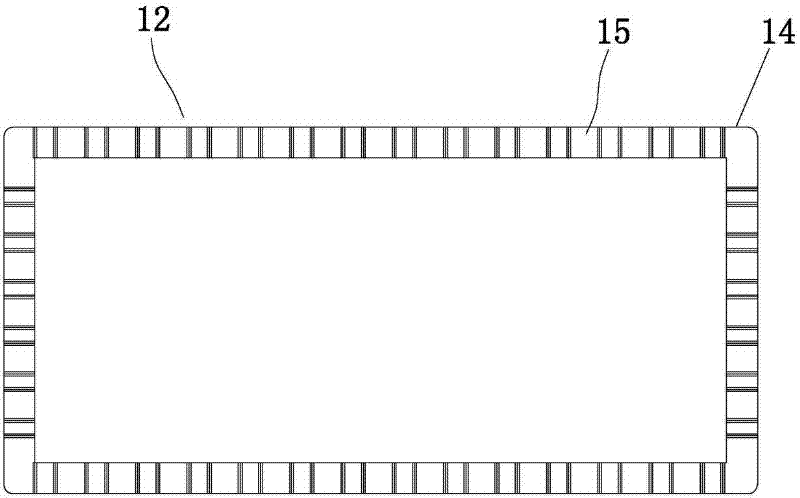

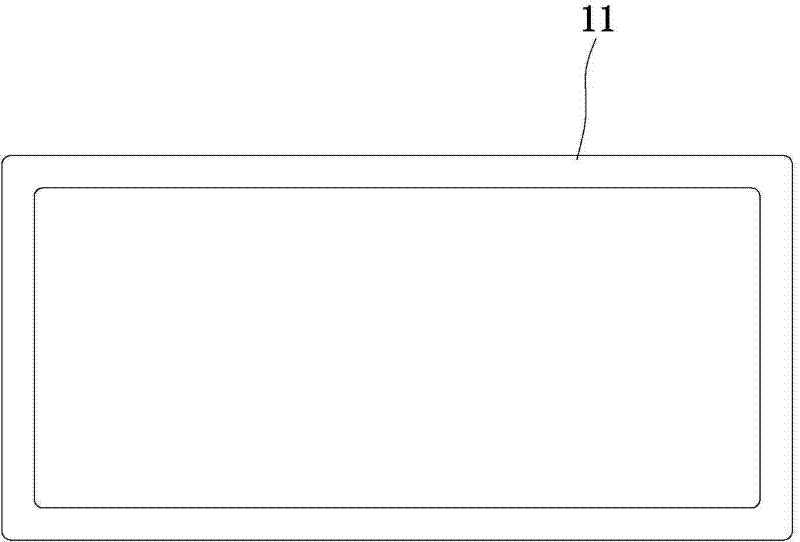

[0016] Referring to the accompanying drawings: the backlog type zinc-air battery cell in this embodiment includes a base frame 1, and an alkali-resistant metal negative plate 2 is sealed and fixed on one side of the base frame 1, and the alkali-resistant metal negative plate 2 is connected to the base The seat frame 1 forms an open fuel tank 3, the fuel tank 3 is covered with zinc paste 4, the fuel tank 3 is sealed with a diaphragm paper 5; the base frame 1 is provided with a liquid replenishment port 6, and the base frame 1 is opened with The liquid replenishment tank 7 communicated with the liquid replenishment port 6, the base frame 1 inside the liquid replenishment tank 7 is provided with a group of liquid inlets 8 communicating with the fuel tank 3, and the base frame 1 outside the liquid replenishment tank 7 is provided with a sealing groove 9 , the sealing groove 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com