Circular comb

A technology for circular combs and combers, which is applied in the field of carding textile fibers, can solve the problems of long set-up time and long downtime of combers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

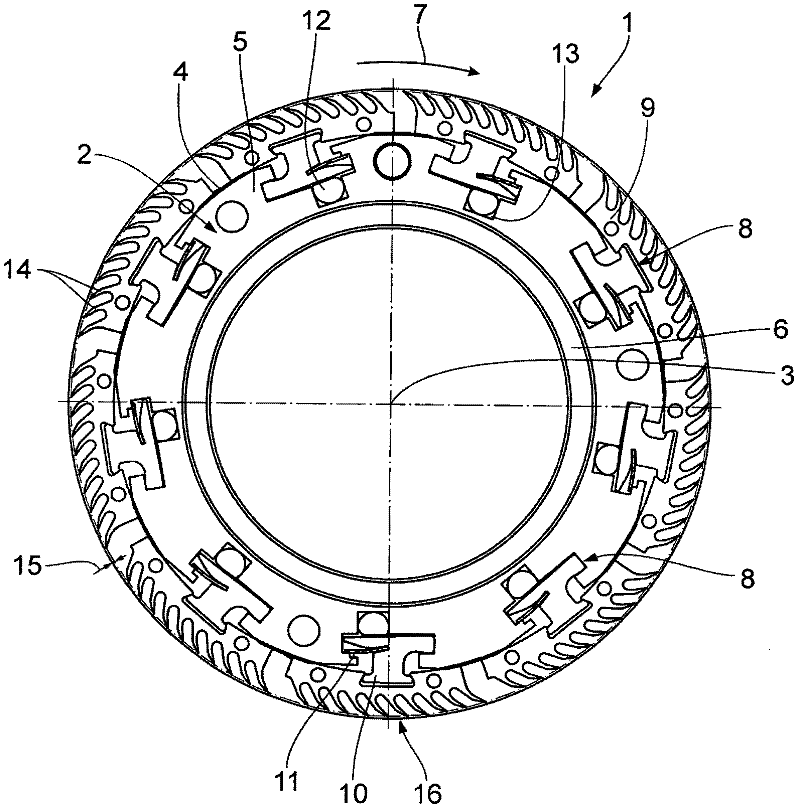

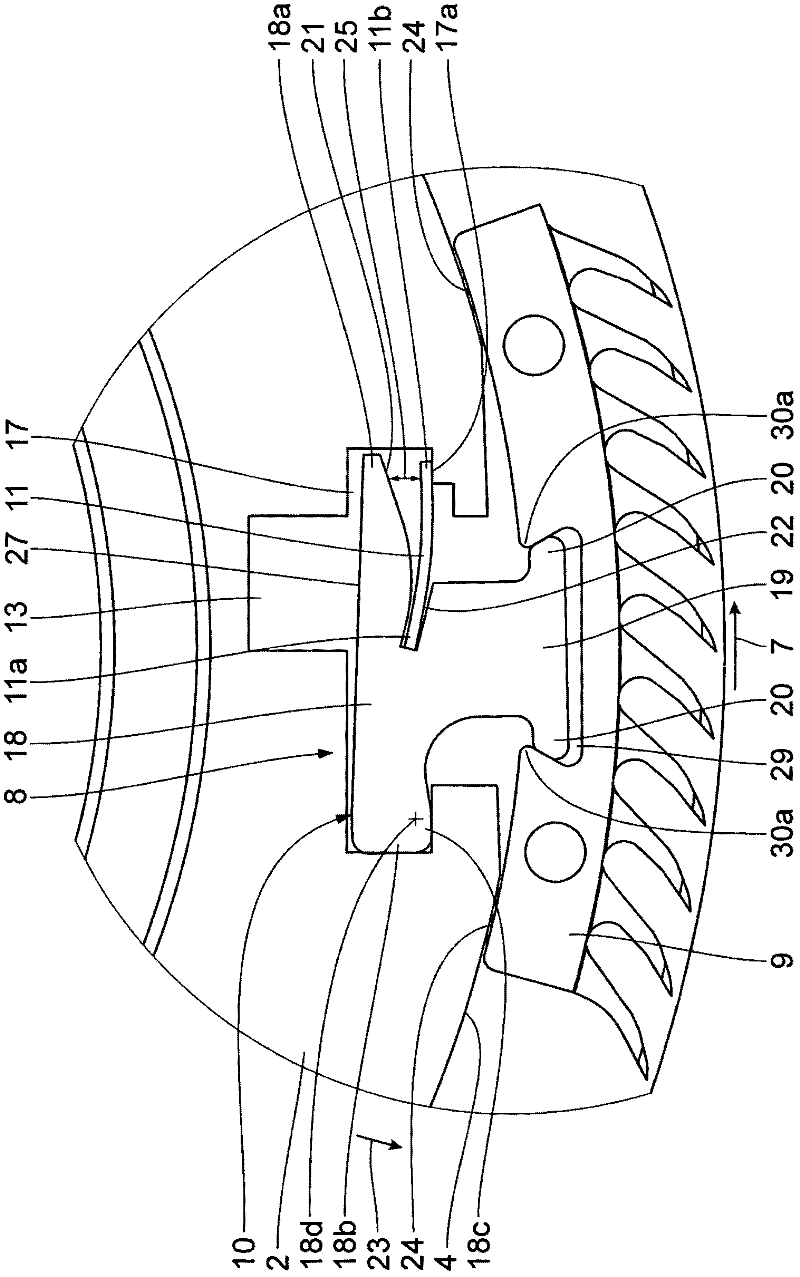

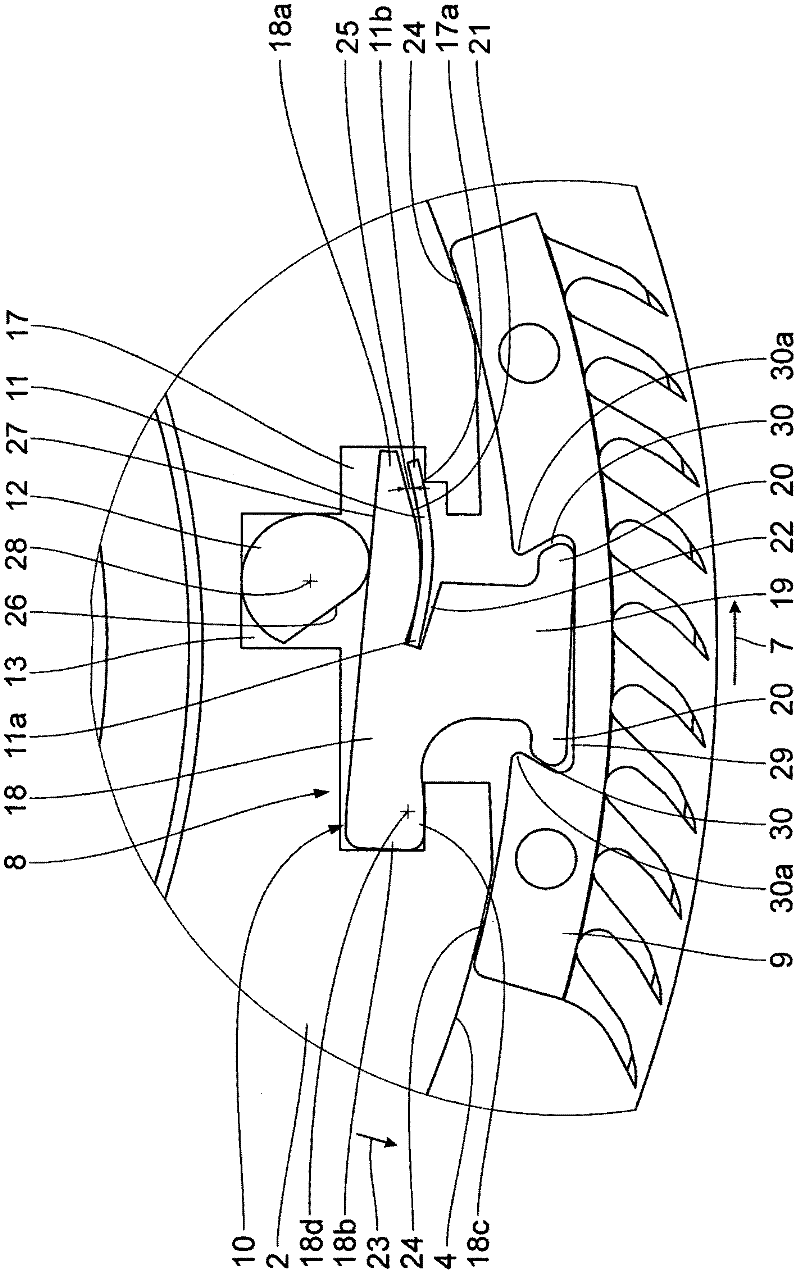

[0047] figure 1 The illustrated circular comb 1 has a hollow cylindrical base body 2 with a central longitudinal axis 3 , outer sides 4 and two end faces 5 (only one of the two end faces is visible). The base body 2 rests on a drive shaft 6 which is likewise designed as a hollow cylinder. The base body 2 can also be driven directly, that is to say without an additional drive shaft 6 . For this purpose, the base body 2 can be designed both as a hollow shaft and as a solid shaft.

[0048] A total of nine positioners 9 are arranged on the base body 2 in the circumferential direction 7 , each fastened by means of a fastening device 8 . The positioner 9 defines the combing area of the circular comb with its axial extension / distribution parallel to the central longitudinal axis 3 .

[0049] Each fixing device 8 comprises a profile 10 and a leaf spring 11 , by means of which each positioner 9 is fastened to the base body 2 in a non-positive manner. For unlocking the non-positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com