Mold-free and rivet-free connection device

A technology of riveting connection and equipment, which is applied in the field of rivetless connection equipment, can solve the problems of large volume, high price, complex structure, etc., and achieve the effect of small volume, simple operation and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

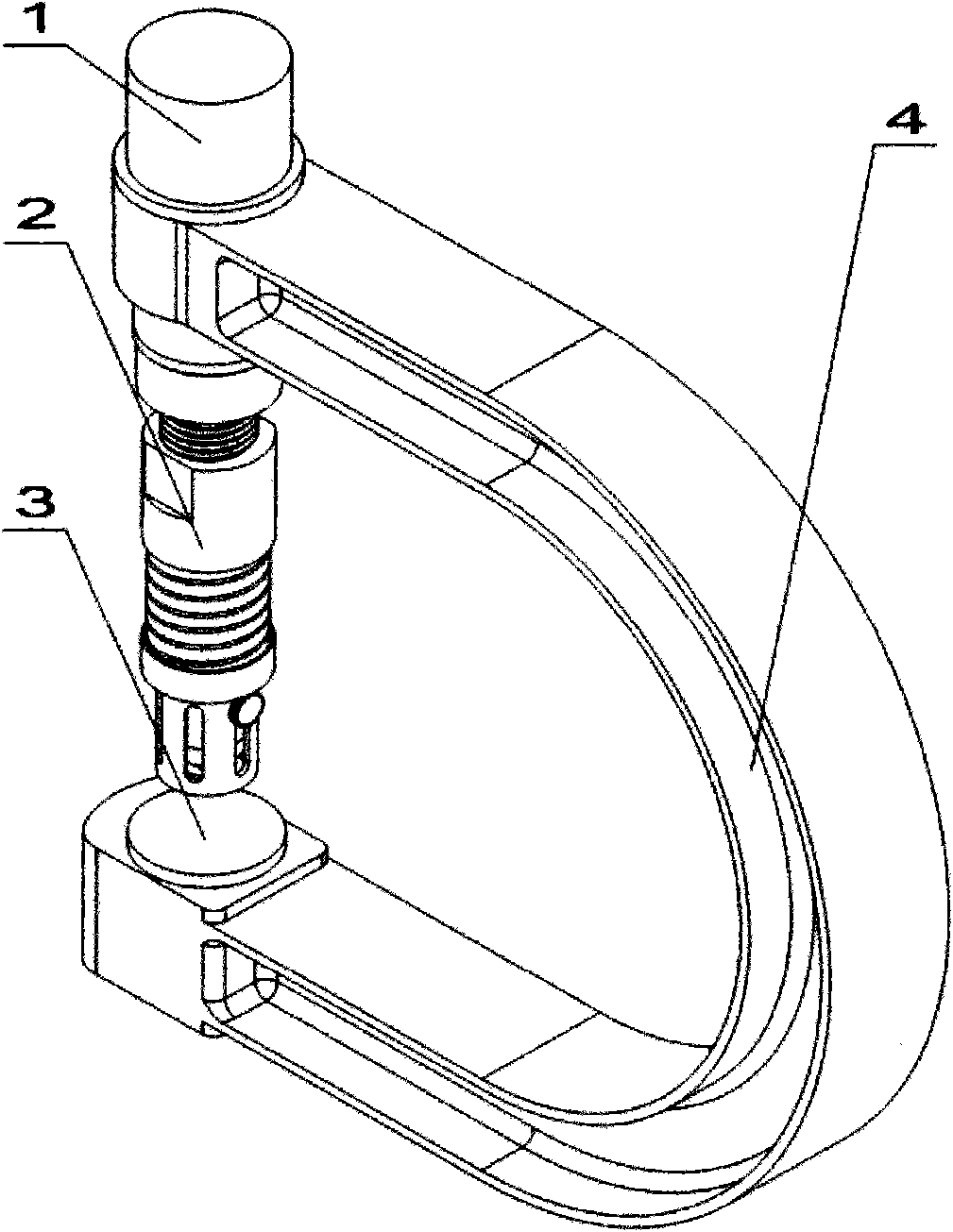

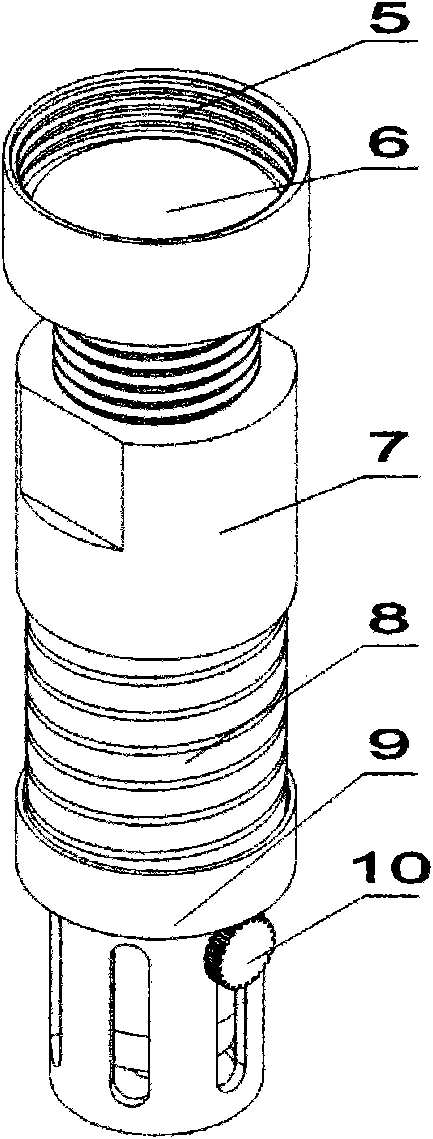

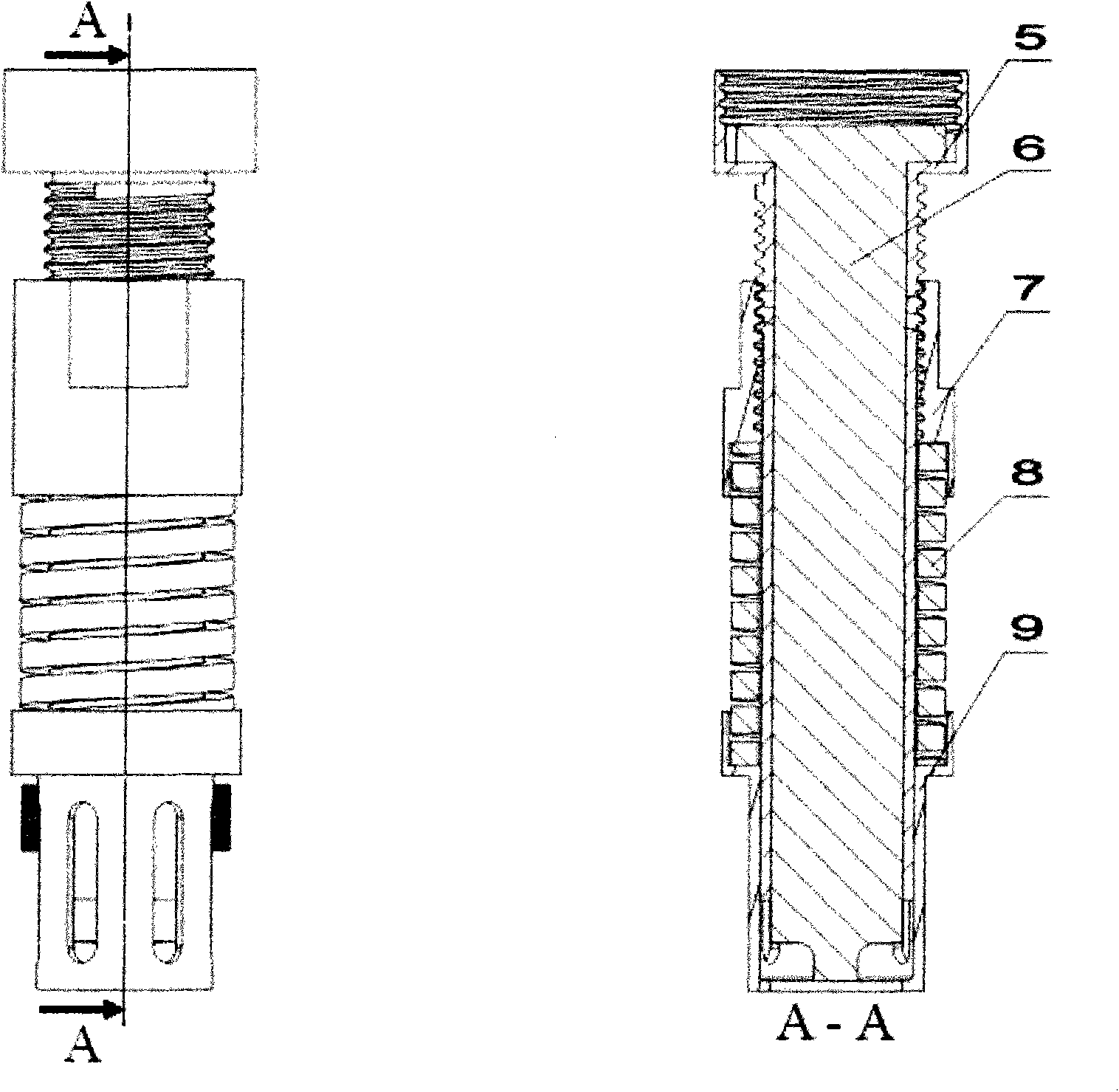

[0014] A kind of moldless and riveted connection equipment of the present invention is realized like this:

[0015] A dieless riveted connection device is composed of a drive motor (1), a punch system (2), a flat anvil (3) and a C-shaped frame (4), wherein the punch system (2) consists of a punch sleeve (5 ), a stepped punch (6), a pressure regulator (7), a spring (8), a blank holder (9) and a positioning pin (10), the lower end of the drive motor (1) is connected to the punch system (2), The punch system (2) can move up and down as a whole driven by the driving motor (1). In the punch system (2), the spring (8) is located between the pressure regulator (7) and the blank holder (9), and the pressure regulator (7) and the punch sleeve (5) are connected through threads, which can be passed Rotate the pressure regulator (7) to adjust its up and down position, so as to adjust the spring force of the initial state and play the role of adjusting the initial pressure of the blank ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com