Transverse rigid rotor blade helicopter

A technology for rotor blades and helicopters, which is applied to rotorcraft, motor vehicles, aircraft parts, etc., can solve the problems of helicopter flight accidents, complicated helicopter manipulation, and complicated flight control, and achieves good maneuverability, high flight aerodynamic efficiency, and rotors. Dynamically simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The accompanying drawings disclose the structural configuration of a preferred embodiment of the present invention without limitation, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

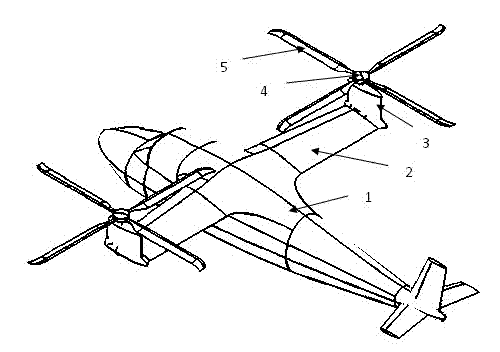

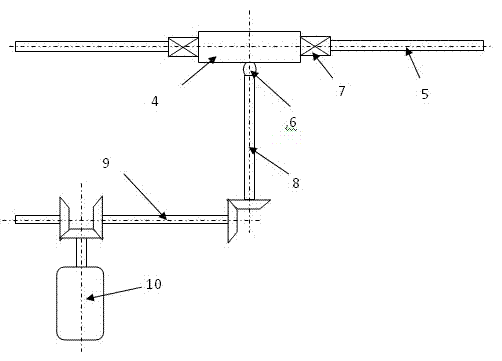

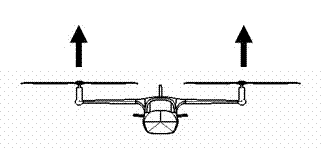

[0045] Such as figure 1 As shown, the tandem rigid rotor blade helicopter of the new configuration of the present invention includes a fuselage 1, a wing 2, a pier 3, a main drive device 10 placed in the fuselage 1, and a main drive device 10 placed in the wing Power transmission shaft 9, rotor drive shaft 8 placed in the pier, universal joint 6, hub 4, axial hinge 7, blade 5. The wing end is fixedly connected with the wing pier. The propeller hub, the axial hinge, and the blades form the rotor, and the axial hinge controls the blades to perform axial variable pitch motion. The rotor has no conventional flapping hinges and shimmy hinges, and the blades do not perform flapping and shimmy motions, so the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com