Blanking box component of novel fodder silo

A storage bin and feed technology, applied in the field of new feed storage bins, can solve the problems of large storage space, easy to be damp and mildew, and achieve the effect of solving mildew, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

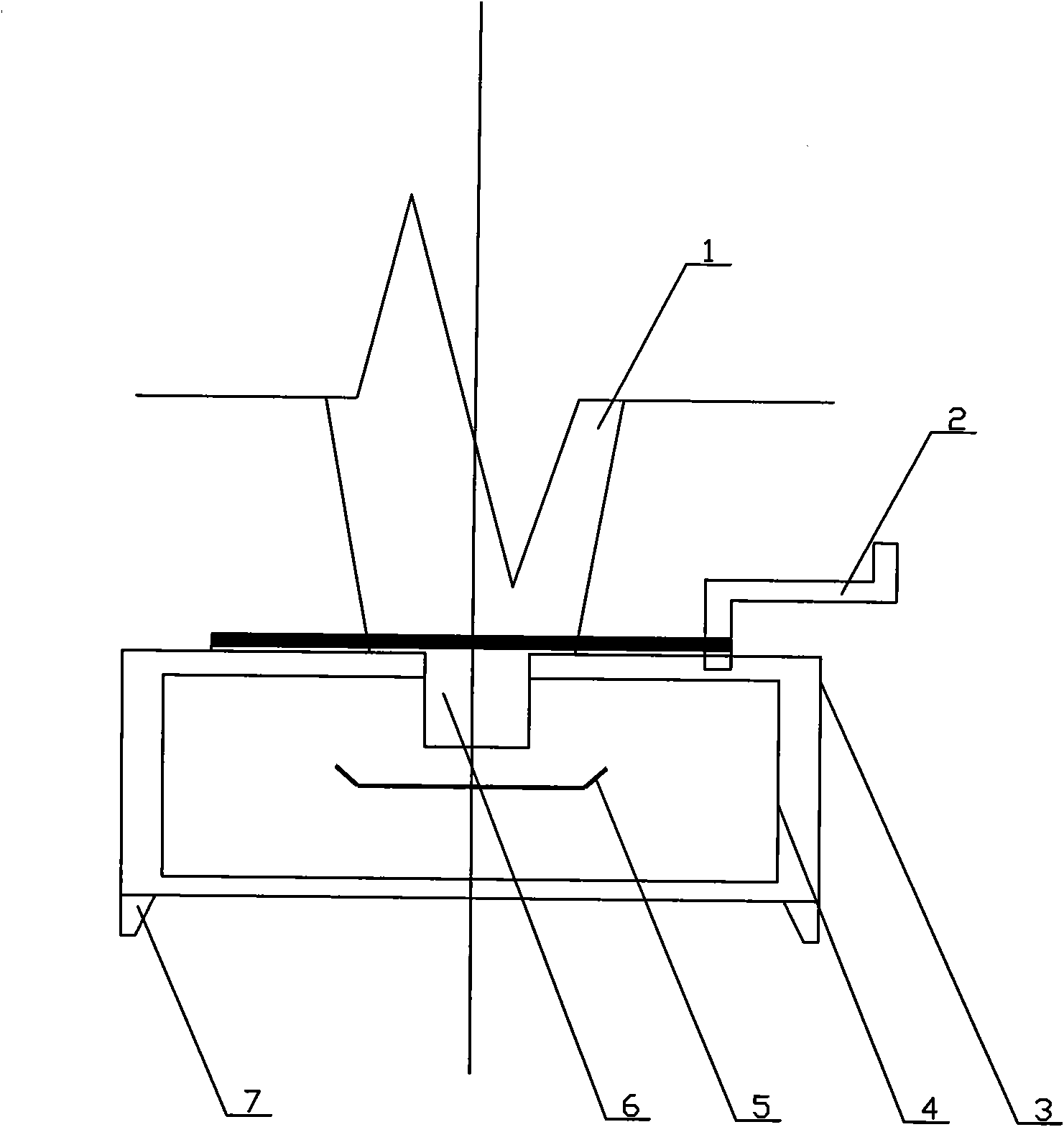

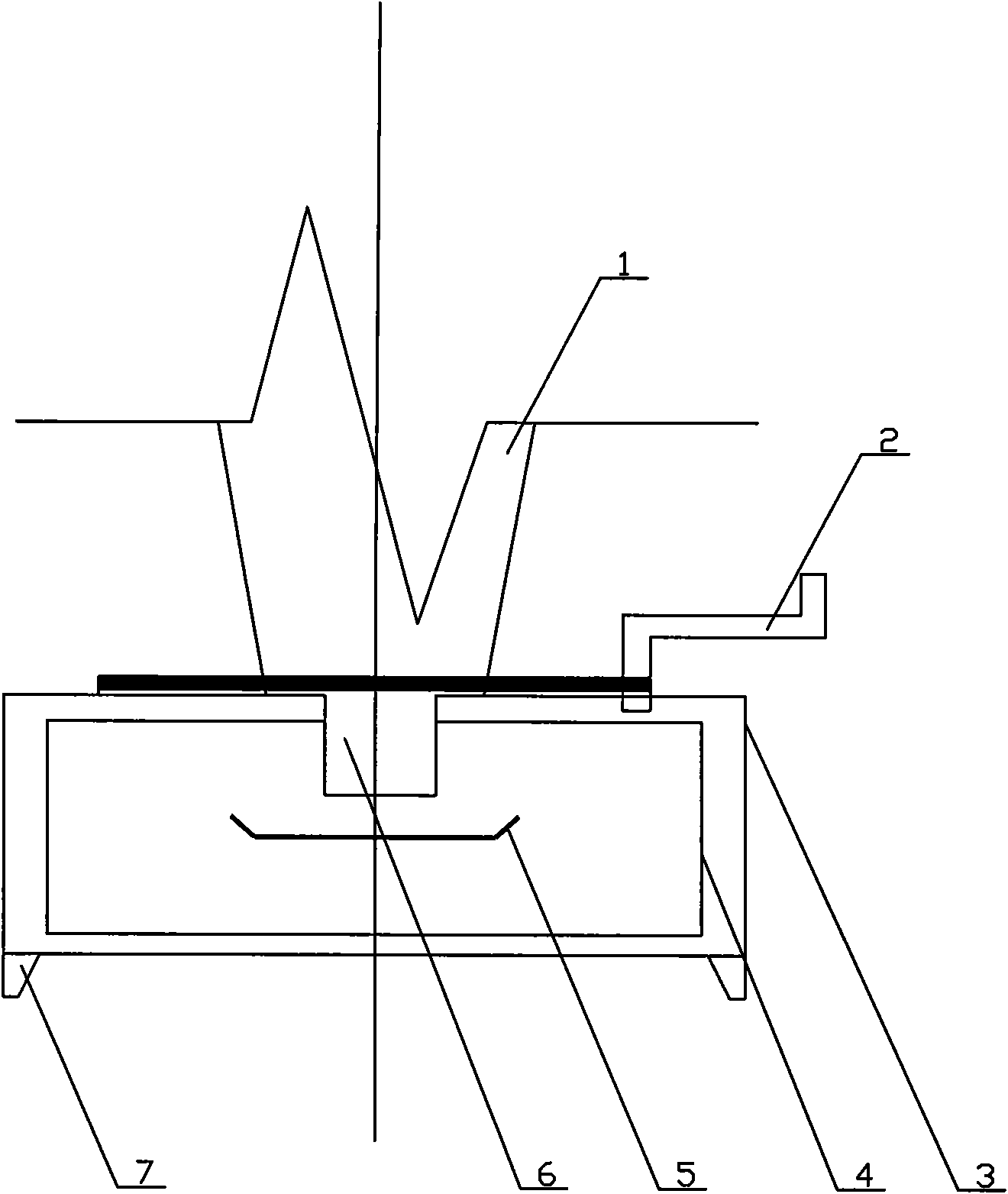

[0006] Such as figure 1 As shown, this specific embodiment adopts the following technical solution: it is composed of a bin body 1, a drawing assembly 2, a housing 3, a drawer 4, a handle 5, a discharge opening 6 and a supporting foot 7. The drawing assembly 2 is arranged at the lower end of the bin body 1, the housing 3 is arranged outside the drawer 4, the handle 5 is arranged at the outermost end of the drawer 4, the feed opening 6 is arranged at the upper end of the housing 3, and the legs 7 It is installed on the four corners of the lower end of the housing 3.

[0007] This specific embodiment has a simple structure, low cost, and can effectively solve the problems of mildew and rodent damage in the background art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com